Understanding units of friction is crucial for various engineering applications. This guide provides a comprehensive look at this topic. The Coulomb friction model, a fundamental concept, characterizes frictional forces between surfaces. Specifically, the coefficient of friction, often measured by organizations such as ASTM International, determines the magnitude of this force. Engineers using software like MATLAB also analyze complex systems where units of friction are important. Exploring the work of experts like Leonardo da Vinci, we can see his notes reveal early explorations of friction concepts. Mastering these units of friction and related principles ensures success in numerous fields.

Imagine trying to walk on a perfectly smooth surface, like a sheet of ice covered in oil. Your feet would slip, and you’d struggle to move forward. This simple scenario highlights the crucial role of friction in our everyday lives. It’s a force we often take for granted, yet it’s fundamental to countless actions, from walking and driving to writing and building.

Friction is everywhere. From the microscopic level of atoms interacting to the macroscopic world of machines and structures, its presence is undeniable.

But what exactly is friction, and why is it so important?

Defining Friction: The Force Resisting Motion

At its core, friction is the force that resists the relative motion of two surfaces in contact. This resistance arises from the microscopic interactions between the surfaces, including adhesion, deformation, and surface roughness.

It opposes movement, converting kinetic energy into thermal energy (heat). That’s why rubbing your hands together makes them warm.

Friction manifests itself in many situations.

Whether it’s the tires of a car gripping the road, the brakes slowing a train, or the gears working in sync inside a machine, friction is the unsung hero (and sometimes the villain) of our physical world.

Friction’s Ubiquitous Presence: From Daily Life to Engineering Marvels

The importance of friction extends far beyond preventing slips and falls. In engineering, friction is a critical factor in designing everything from efficient engines to stable bridges.

Understanding and controlling friction is essential for optimizing performance, reducing wear and tear, and ensuring safety.

Consider the design of a car engine. Engineers must carefully consider friction between moving parts to maximize efficiency and minimize energy loss.

Similarly, in the construction of a skyscraper, friction between the foundation and the ground plays a vital role in ensuring stability and preventing collapse.

Even in the seemingly simple act of writing with a pen, friction between the pen tip and the paper allows us to create marks and communicate our thoughts.

Understanding and Converting Friction-Related Concepts

This article delves into the fascinating world of friction, exploring its various types, the factors that influence it, and its practical applications.

We will examine the relationship between friction force, normal force, and the coefficient of friction, providing you with the tools to quantify and analyze frictional phenomena.

The goal is to provide you with a solid understanding of the fundamental principles.

Scope and Practical Examples

We’ll explore the differences between static and kinetic friction and discover how the coefficient of friction varies depending on the materials in contact and the surface conditions.

Through real-world examples, you’ll learn how to calculate the force required to overcome static friction, determine the coefficient of friction from experimental data, and analyze kinetic friction in various scenarios.

By the end of this article, you’ll have a deeper appreciation for the pervasive influence of friction and its critical role in shaping our world.

Consider the simple act of pushing a heavy box. It might not budge at first, no matter how hard you push. Then, with a little more effort, it suddenly starts to slide. This everyday experience hints at the fascinating complexity hidden within the seemingly simple concept of friction. In reality, friction manifests itself in several distinct forms, each with its own unique characteristics and behaviors.

The Many Faces of Friction: Exploring Different Types

Friction isn’t a singular entity; rather, it’s a family of forces that govern how surfaces interact. Understanding these different types of friction is crucial for effectively predicting and controlling motion in various scenarios. We will explore two primary types: static and kinetic friction. Each plays a unique role in determining whether an object remains at rest or begins to move, and how it behaves once in motion. We’ll also examine the overarching concept of friction force and how it applies to everyday situations.

Static Friction: The Force That Prevents Motion

Static friction is the force that prevents an object from starting to move when a force is applied to it. It’s a reactive force that adjusts itself to match the applied force, up to a certain limit. Think of it as an invisible barrier that must be overcome before movement can occur.

Maximum Static Friction

The magnitude of static friction can vary, increasing as the applied force increases. However, it has a maximum value, often denoted as fs,max. This maximum value represents the threshold that must be exceeded to initiate motion. Once the applied force surpasses fs,max, the object will begin to move, and static friction is replaced by kinetic friction.

The relationship between maximum static friction (fs,max), the coefficient of static friction (μs), and the normal force (N) is given by:

fs,max = μs N

This equation highlights that the maximum static friction is directly proportional to both the normal force and the coefficient of static friction.

Real-World Examples of Static Friction

Static friction is evident in countless everyday situations. A book resting on a table remains stationary due to static friction between the book’s surface and the table’s surface. Similarly, a car parked on a hill relies on static friction between its tires and the road to prevent it from rolling downhill. Even the simple act of standing relies on static friction between your shoes and the ground to keep you from slipping.

Kinetic Friction: The Force Opposing Motion

Kinetic friction, also known as dynamic friction, is the force that opposes the motion of an object already in motion. Unlike static friction, kinetic friction has a constant magnitude that doesn’t depend on the applied force. It acts to slow down or resist the sliding of one surface over another.

Kinetic Friction vs. Static Friction

A key difference between kinetic and static friction is that kinetic friction is typically lower than the maximum static friction. This is why it takes more force to start an object moving than it does to keep it moving. Once an object is in motion, the frictional force opposing its movement is reduced.

The relationship between kinetic friction (fk), the coefficient of kinetic friction (μk), and the normal force (N) is given by:

fk = μk N

Real-World Examples of Kinetic Friction

Kinetic friction is readily observed in many everyday scenarios. Sliding a box across the floor involves kinetic friction between the box’s bottom surface and the floor. Similarly, a car braking relies on kinetic friction between the brake pads and the rotors to slow the car down. Ice skating is possible because the kinetic friction between the blade and the ice is low, allowing for relatively easy gliding.

Friction Force: The Umbrella Term

The term "friction force" is often used as an umbrella term to refer to either static or kinetic friction. It simply represents the force resisting motion between surfaces in contact.

Friction Force in Everyday Life

Friction force is a fundamental aspect of daily life. It’s essential for walking, driving, writing, and countless other activities. Without friction, we wouldn’t be able to grip objects, and movement would be nearly impossible. While we often focus on overcoming friction, it’s also crucial for many processes such as sanding wood or polishing surfaces. Both static and kinetic friction play vital roles, depending on whether an object is at rest or in motion.

Friction, as we’ve seen, manifests as forces that resist motion, whether an object is at rest or sliding. But how do we quantify this resistance? This is where the coefficient of friction enters the picture, providing a crucial link between friction force and another fundamental force: the normal force.

Coefficient of Friction (μ): The Key to Quantification

The coefficient of friction (μ) is a dimensionless quantity.

It serves as a crucial index representing the relative roughness or slipperiness between two surfaces in contact.

Essentially, it’s a ratio that tells us how much force is needed to overcome friction, relative to the force pressing the surfaces together.

Defining the Coefficient of Friction (μ)

At its core, the coefficient of friction (μ) is defined as the ratio of the friction force (Ff) to the normal force (Fn):

μ = Ff / Fn

This simple equation unlocks a powerful tool for predicting and analyzing frictional behavior.

It allows engineers and scientists to estimate the friction force between two surfaces based on their material properties and the normal force acting upon them.

The coefficient of friction is dimensionless because it’s a ratio of two forces, and the units cancel out.

Static (μs) vs. Kinetic (μk) Coefficients

It’s important to recognize that friction isn’t a one-size-fits-all phenomenon. We distinguish between two primary types of coefficients: static (μs) and kinetic (μk).

Static Coefficient of Friction (μs)

The static coefficient of friction (μs) applies when an object is at rest.

It represents the ratio of the maximum static friction force to the normal force just before the object begins to move.

In most cases, μs is greater than μk. It generally requires more force to initiate movement than to sustain it.

Think back to that heavy box. The force needed to initially budge the box (static friction) is often greater than the force needed to keep it sliding (kinetic friction).

Kinetic Coefficient of Friction (μk)

The kinetic coefficient of friction (μk), also known as the dynamic coefficient, applies when an object is already in motion.

It represents the ratio of the kinetic friction force to the normal force while the object is sliding.

This value is usually lower than the static coefficient.

The smoother, ongoing interaction between the surfaces during motion results in less frictional resistance.

Factors Influencing the Coefficient of Friction (μ)

While the coefficient of friction provides a useful approximation, it’s not a fundamental property of a material alone. Several factors can influence its value:

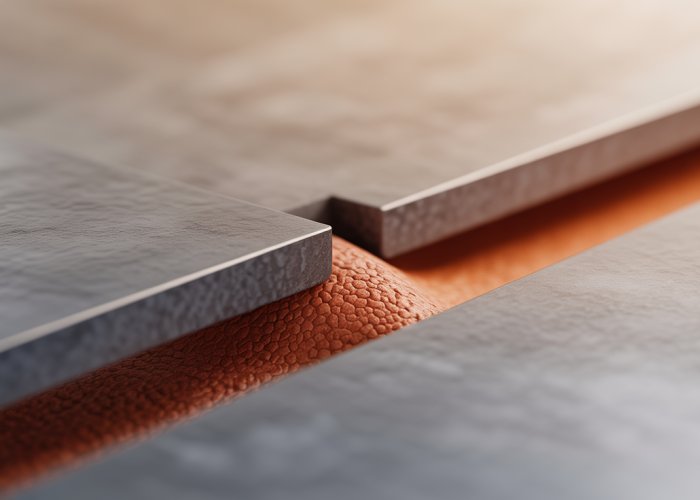

- Materials: The types of materials in contact have the most significant impact. Rubber on asphalt will have a much higher coefficient of friction than ice on ice.

- Surface Conditions: The roughness or smoothness of the surfaces plays a crucial role. A rough surface will generally have a higher coefficient of friction than a smooth one. However, extreme smoothness can also lead to increased friction due to adhesion.

- Temperature: Temperature can affect the properties of the materials, which in turn can influence the coefficient of friction.

- Lubrication: The presence of a lubricant between the surfaces can significantly reduce the coefficient of friction.

- Surface Contamination: Dirt, oil, or other contaminants can alter the surface properties and change the coefficient of friction.

It’s important to consider these factors when using the coefficient of friction in calculations and analyses.

The Role of Normal Force

The normal force is the force exerted by a surface that supports the weight of an object. It acts perpendicular to the surface of contact.

It’s not always equal to the object’s weight; it can be affected by other applied forces.

For example, if you push down on a box resting on the floor, you increase the normal force.

Relationship Between Normal Force and Friction Force

The normal force directly influences the friction force.

A greater normal force means that the surfaces are pressed together with greater force.

This result generally leads to a higher friction force and vice versa.

Variables Affecting Normal Force

Several factors can influence the normal force:

- Weight of the Object: The object’s weight is a primary contributor to the normal force, especially on horizontal surfaces.

- Applied Forces: Any external force acting perpendicular to the surface will affect the normal force. A downward force increases it, while an upward force decreases it.

- Angle of the Surface: On an inclined plane, the normal force is equal to the component of the object’s weight that is perpendicular to the surface.

Understanding these variables is crucial for accurately determining the normal force and, consequently, the friction force.

Friction, as we’ve seen, manifests as forces that resist motion, whether an object is at rest or sliding. But how do we quantify this resistance? This is where the coefficient of friction enters the picture, providing a crucial link between friction force and another fundamental force: the normal force.

Units and Their Significance: Deciphering the Measurements

While the coefficient of friction elegantly describes the relationship between forces, it’s essential to understand the units in which these forces themselves are measured. This section explores the significance of the coefficient of friction as a dimensionless quantity and delves into the units used to measure force, particularly Newtons and pounds-force, clarifying their relationship to the normal force and their role in friction calculations.

The Dimensionless Nature of the Coefficient of Friction (μ)

The coefficient of friction (μ) stands out as a dimensionless quantity. This means it’s a pure number, lacking any physical units like meters, kilograms, or seconds.

Why is this important? Because μ represents a ratio – the ratio of the friction force to the normal force.

Since both friction force and normal force are measured in the same units (e.g., Newtons), the units cancel out in the division, leaving a pure number.

This dimensionless nature allows us to compare the slipperiness or roughness of different surfaces regardless of the specific units used to measure the forces involved.

Measuring Force: Newtons and Pounds-force

Force, in general, is measured in units that reflect its ability to accelerate a mass.

The two most common units are Newtons (N) and pounds-force (lbf).

-

Newton (N): In the International System of Units (SI), the standard unit of force is the Newton. One Newton is defined as the force required to accelerate a 1-kilogram mass at a rate of 1 meter per second squared (1 N = 1 kg⋅m/s²).

It’s a derived unit, built upon the fundamental units of mass, length, and time.

-

Pound-force (lbf): In the imperial system, force is often measured in pounds-force. One pound-force is approximately the force exerted by gravity on a mass of one pound.

While less common in scientific contexts, it remains prevalent in engineering and everyday applications in some regions.

The Interplay of Force, Normal Force, and the Coefficient of Friction

Understanding the relationship between force, normal force, and the coefficient of friction is crucial for applying these concepts effectively.

The normal force (Fn) is the force exerted by a surface that supports the weight of an object, acting perpendicularly to the surface.

The friction force (Ff) is directly proportional to the normal force, with the coefficient of friction (μ) acting as the constant of proportionality.

This relationship, expressed by the equation Ff = μFn, underscores that the friction force is not just about the materials in contact; it is also dependent on how strongly those surfaces are pressed together.

Increasing the normal force increases the friction force.

The coefficient of friction (μ) dictates how much the friction force increases for a given increase in the normal force.

Overview of Units of Measurement in Friction

In summary, when dealing with friction, it is essential to keep track of the units involved:

- Coefficient of Friction (μ): Dimensionless (no units).

- Friction Force (Ff): Measured in Newtons (N) or pounds-force (lbf).

- Normal Force (Fn): Measured in Newtons (N) or pounds-force (lbf).

By understanding these units and their relationships, you can accurately analyze and predict frictional behavior in various scenarios, ensuring consistency and accuracy in calculations.

Friction, as we’ve seen, manifests as forces that resist motion, whether an object is at rest or sliding. But how do we quantify this resistance? This is where the coefficient of friction enters the picture, providing a crucial link between friction force and another fundamental force: the normal force.

Beyond the Basics: Exploring Additional Factors Influencing Friction

While the concepts of static and kinetic friction provide a solid foundation for understanding how surfaces interact, the world of friction is far more complex than these models suggest. Several additional factors come into play in real-world scenarios, influencing the magnitude and behavior of frictional forces. Let’s delve into two key areas that extend our understanding: tribology and rolling friction.

Tribology: The Intricate Science of Interacting Surfaces

Tribology is the science and engineering of interacting surfaces in relative motion. It encompasses the study of friction, wear, and lubrication.

Unlike simplified models that treat surfaces as perfectly smooth, tribology recognizes that real-world surfaces are characterized by roughness, asperities (microscopic peaks and valleys), and complex chemical and physical properties.

Understanding these surface characteristics is crucial for predicting and controlling friction and wear in various applications, from designing more efficient engines to developing durable artificial joints.

The Role of Surface Roughness

The roughness of a surface significantly impacts friction. Rougher surfaces tend to interlock more, leading to higher friction. However, the relationship isn’t always straightforward.

Extremely rough surfaces may have fewer points of contact due to the peaks bearing the entire load, which can, paradoxically, reduce friction.

Lubrication: Minimizing Friction

Lubrication is a key aspect of tribology, focusing on reducing friction and wear by introducing a lubricant between interacting surfaces.

Lubricants can be liquids (oils), solids (graphite), or gases (air), and their effectiveness depends on factors such as viscosity, pressure, and surface properties.

Lubrication can reduce friction by:

- Separating the surfaces, preventing direct contact.

- Reducing the shear strength of the interface.

- Carrying away heat generated by friction.

Rolling Friction: Understanding Resistance to Rolling Motion

While static and kinetic friction describe resistance to sliding, rolling friction describes the resistance encountered when one object rolls over another. It’s a force that opposes rolling motion and is typically much smaller than kinetic friction.

Factors Influencing Rolling Friction

Several factors influence the magnitude of rolling friction:

- Deformation of the rolling object and the surface: When a wheel rolls on a surface, both deform slightly. This deformation creates a contact area, and energy is lost as the materials are deformed and then recover.

- Material properties: The elasticity and hardness of the materials involved affect the amount of deformation and energy loss.

- Diameter of the rolling object: Larger diameter rollers generally experience lower rolling friction.

- Surface roughness: While less significant than in sliding friction, surface roughness still plays a role in rolling friction.

Rolling Friction vs. Sliding Friction: A Comparison

Rolling friction is generally much lower than sliding friction. This is why wheeled vehicles are far more efficient than dragging an object across a surface.

In rolling, the contact between surfaces is constantly changing and the deformations are usually less severe than the continuous abrasion in sliding.

The lower friction translates to less energy loss and greater efficiency in transportation and machinery.

Friction, as we’ve seen, manifests as forces that resist motion, whether an object is at rest or sliding. But how do we quantify this resistance? This is where the coefficient of friction enters the picture, providing a crucial link between friction force and another fundamental force: the normal force.

Practical Friction: Applying the Concepts with Real-World Examples

The theoretical understanding of friction gains true value when applied to practical situations. By examining real-world scenarios, we can see how the principles of static and kinetic friction, along with the coefficient of friction, dictate the forces at play. Let’s explore a few examples where we put these concepts into action.

Example 1: Calculating the Force Required to Overcome Static Friction

Imagine trying to push a heavy crate across a concrete floor. Before the crate starts to move, you are dealing with static friction, the force that prevents initial motion.

To calculate the force needed to overcome this static friction, we use the formula:

Fstatic ≤ μs Fnormal

**

Where:

- Fstatic is the static friction force.

- μs is the coefficient of static friction between the crate and the floor.

- Fnormal is the normal force, which is typically equal to the weight of the crate (mass** gravity).

Let’s say the crate weighs 500 N (Newtons), and the coefficient of static friction between the crate and the concrete floor is 0.6.

Then, the maximum static friction force is:

Fstatic ≤ 0.6 500 N = 300 N

**

This means you need to apply a force greater than 300 N to get the crate moving. If you apply a force less than 300 N, the static friction will match your applied force, and the crate won’t budge.

Only when your applied force exceeds 300 N will you overcome static friction and initiate movement.

Example 2: Determining the Coefficient of Friction from Experimental Data

In many real-world situations, the coefficient of friction isn’t readily available. Instead, it must be determined experimentally.

Consider an experiment where a block is pulled horizontally across a table at a constant speed. A force sensor measures the pulling force, and the weight of the block provides the normal force.

Since the block moves at a constant speed, we know the pulling force is equal to the kinetic friction force.

The formula for kinetic friction is:

Fkinetic = μk Fnormal**

Where:

- Fkinetic is the kinetic friction force.

- μk is the coefficient of kinetic friction.

- Fnormal is the normal force.

Let’s say the block weighs 20 N, and the force sensor reads 5 N while the block is sliding at a constant speed. To find the coefficient of kinetic friction, we rearrange the formula:

μk = Fkinetic / Fnormal = 5 N / 20 N = 0.25

Therefore, the coefficient of kinetic friction between the block and the table is 0.25. This experimental method allows us to determine the μk value for various material pairings.

Example 3: Analyzing Kinetic Friction in a Sliding Motion Scenario

Once an object is in motion, kinetic friction becomes the dominant force. Let’s analyze a scenario where a hockey puck slides across an ice rink.

The puck has an initial velocity, but due to kinetic friction, it gradually slows down and eventually comes to a stop. To analyze this, we need to consider Newton’s Second Law of Motion:

F = ma

Where:

- F is the net force acting on the puck.

- m is the mass of the puck.

- a is the acceleration of the puck.

In this case, the net force is the kinetic friction force, acting in the opposite direction of the puck’s motion. Therefore:

-Fkinetic = ma

And since:

Fkinetic = μk Fnormal

**

We can rewrite the equation as:

-μk Fnormal = ma**

Assuming the ice rink is level, the normal force is equal to the weight of the puck (mg). Thus:

-μk mg = ma

**

Dividing both sides by m, we get:

a = -μk g**

This tells us the acceleration of the puck is constant and negative, meaning the puck is decelerating. Knowing the initial velocity and the acceleration, we can use kinematic equations to determine the distance the puck travels before stopping or the time it takes to stop.

This analysis demonstrates how kinetic friction affects the motion of an object and how it can be quantified using the coefficient of kinetic friction. These real-world examples highlight the direct application of friction concepts, from overcoming static friction to determining coefficients through experimentation and analyzing motion influenced by kinetic friction.

FAQs: Understanding Friction Unit Conversions

Here are some frequently asked questions to help you further understand the units of friction and their conversions.

What exactly do we mean by "units of friction"?

The term "units of friction" often refers to the various ways the coefficient of friction (μ) is expressed or used in calculations. While μ itself is dimensionless, understanding how it interacts with different units of force (e.g., Newtons, pounds) is key to friction calculations.

Why is the coefficient of friction dimensionless?

The coefficient of friction is a ratio – the ratio of the frictional force to the normal force. Because it’s a ratio of two forces, the units cancel out, leaving a dimensionless value. This means the value of the coefficient remains the same regardless of the units used to measure force.

How do I ensure consistent results when working with friction and different units?

While the coefficient of friction is dimensionless, you must ensure consistency in the units used for force. If you’re using Newtons for the normal force, the frictional force will also be in Newtons. Mixing units (e.g., pounds for normal force, Newtons for frictional force) will lead to incorrect results.

What happens if I mistakenly use incorrect units when calculating friction?

Using inconsistent or incorrect units will result in an inaccurate calculation of the frictional force. Your answer could be off by several orders of magnitude, leading to potentially dangerous outcomes in engineering or design applications involving units of friction. Always double-check your units!

And there you have it! Hopefully, this guide has cleared up any confusion about units of friction and helped you feel more confident working with them. Now go out there and put that knowledge to good use!