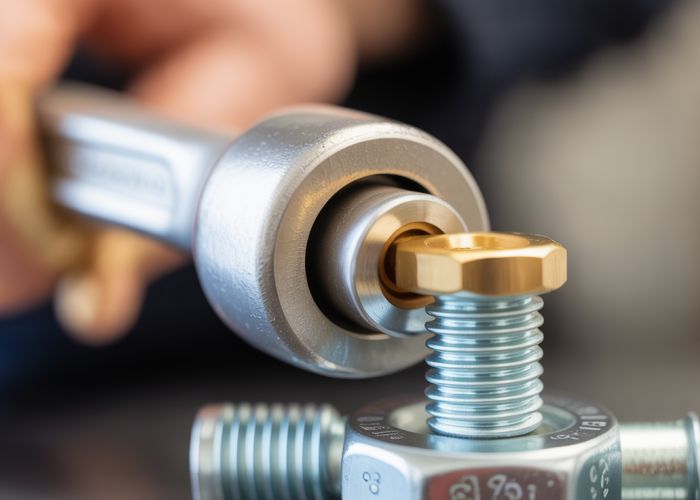

Torque wrench accuracy is crucial for reliable bolted joint integrity, a core principle in the aerospace sector where Snap-on Industrial tools are often employed. A properly calibrated torque wrench, a precision instrument, ensures fastener tension meets specified engineering standards. Incorrect settings can lead to catastrophic failures, making regular calibration services at facilities like Accurate Calibration essential for maintaining safety and operational excellence.

Understanding Torque Wrench Accuracy and Calibration

Torque wrench accuracy is paramount for ensuring proper fastener tightening, preventing both under-tightening (leading to joint failure) and over-tightening (potentially damaging components). Determining whether your torque wrench is accurately delivering the specified torque value is crucial for maintaining safety and performance. This explanation will break down the key aspects related to torque wrench accuracy and calibration.

Why Torque Wrench Accuracy Matters

A torque wrench is designed to apply a specific amount of rotational force, or torque, to a fastener. Deviations from this specified torque can have severe consequences:

- Under-tightening: Fasteners may loosen over time due to vibration or stress, leading to joint failure, leaks, or component damage.

- Over-tightening: Fasteners or the materials they are securing can be damaged, stripped, or weakened. This can also compromise the integrity of the entire assembly.

- Safety Concerns: In critical applications like automotive or aerospace, inaccurate torque can lead to catastrophic failures and potentially dangerous situations.

Factors Affecting Torque Wrench Accuracy

Several factors can influence the accuracy of a torque wrench over time:

- Wear and Tear: Frequent use can cause internal components to wear down, affecting the wrench’s ability to measure torque accurately.

- Improper Storage: Storing a torque wrench incorrectly (e.g., leaving it set at a high torque value) can weaken the internal spring and reduce accuracy.

- Overloading: Exceeding the wrench’s maximum torque capacity can damage internal mechanisms and calibration.

- Environmental Conditions: Temperature and humidity fluctuations can affect the materials within the wrench, impacting accuracy.

- User Error: Applying torque incorrectly (e.g., not pulling smoothly or at the correct angle) can lead to inaccurate readings.

Types of Torque Wrenches and Their Accuracy

Different types of torque wrenches offer varying levels of accuracy and precision:

- Click-Type Torque Wrenches: These are the most common type and provide an audible "click" when the set torque is reached. Their accuracy typically ranges from +/- 3% to +/- 4%.

- Beam-Type Torque Wrenches: These wrenches use a pointer and scale to indicate the applied torque. They are generally less accurate than click-type wrenches, typically +/- 5%.

- Digital Torque Wrenches: These wrenches use electronic sensors to measure torque and display the reading digitally. They offer high accuracy, often +/- 1% or better, and can store data.

- Hydraulic Torque Wrenches: Used for high-torque applications, these wrenches employ hydraulic pressure to apply torque. Their accuracy varies but can be very high with proper calibration.

The following table summarizes the common torque wrench types and their typical accuracy ranges:

| Torque Wrench Type | Typical Accuracy | Advantages | Disadvantages |

|---|---|---|---|

| Click-Type | +/- 3% to +/- 4% | Easy to use, audible indication, relatively affordable | Can be less accurate than digital wrenches |

| Beam-Type | +/- 5% | Simple design, durable, no need for calibration in some designs | Lower accuracy, requires careful visual monitoring of the scale |

| Digital | +/- 1% or better | High accuracy, digital display, data storage capabilities | More expensive, requires battery power |

| Hydraulic | Varies | High torque capacity, precise control | Complex operation, specialized equipment required |

Determining if Your Torque Wrench Needs Calibration

Regularly checking and calibrating your torque wrench is crucial for maintaining its accuracy. Here are some signs that your wrench may need calibration:

- Dropped or Damaged: If the wrench has been dropped or subjected to physical trauma, it should be checked for accuracy.

- Frequent Use: Wrenches used daily should be calibrated more frequently than those used occasionally.

- Uncertainty About Readings: If you suspect that the wrench is not providing accurate readings, it’s best to have it calibrated.

- Exceeding Torque Capacity: Overloading the wrench can damage internal components and affect accuracy.

- Elapsed Time: Even if the wrench is not used frequently, it should be calibrated periodically (e.g., every 6-12 months) to account for potential drift.

The Calibration Process

Torque wrench calibration involves comparing the wrench’s output to a known standard. This process typically includes the following steps:

- Visual Inspection: The wrench is inspected for any signs of damage or wear.

- Cleaning: The wrench is cleaned to remove any dirt or debris that could affect accuracy.

- Calibration Testing: The wrench is tested at multiple torque values using a calibrated torque analyzer. This analyzer measures the actual torque applied by the wrench.

- Adjustment (if needed): If the wrench is found to be out of calibration, adjustments are made to bring it back within the specified tolerance.

- Certification: A calibration certificate is issued, documenting the wrench’s accuracy and traceability to national or international standards.

Where to Get Your Torque Wrench Calibrated

Torque wrenches should be calibrated by a qualified calibration laboratory. These labs have the necessary equipment and expertise to accurately assess and adjust torque wrenches. When choosing a calibration lab, look for the following:

- Accreditation: Ensure the lab is accredited to ISO/IEC 17025, demonstrating its competence in calibration services.

- Traceability: Verify that the lab’s standards are traceable to national or international metrology institutes (e.g., NIST in the United States).

- Calibration Certificate: The lab should provide a detailed calibration certificate documenting the results of the calibration.

- Turnaround Time and Cost: Inquire about the lab’s turnaround time and cost for calibration services.

Maintaining Torque Wrench Accuracy

Proper care and maintenance can help prolong the life and accuracy of your torque wrench:

- Storage: Store the wrench in its case or a designated location to protect it from damage. Release the tension on the spring by setting the wrench to its lowest torque setting.

- Cleaning: Clean the wrench regularly with a soft cloth. Avoid using solvents or harsh chemicals that could damage internal components.

- Handling: Handle the wrench with care and avoid dropping it or subjecting it to unnecessary shocks.

- Proper Use: Use the wrench correctly, applying torque smoothly and at the proper angle. Follow the manufacturer’s instructions.

- Calibration: Calibrate the wrench regularly, following the recommended calibration interval.

Torque Wrench Accuracy: Frequently Asked Questions

Here are some common questions about torque wrench accuracy and calibration, helping you ensure your tools are working correctly.

How often should I calibrate my torque wrench?

Generally, a torque wrench should be calibrated every 5,000 uses or every 12 months, whichever comes first. Regular calibration ensures consistent torque wrench accuracy. For high-use or critical applications, more frequent calibration is recommended.

What happens if my torque wrench is out of calibration?

If your torque wrench isn’t calibrated, the applied torque will be inaccurate. Over-tightening can damage fasteners or components, while under-tightening can lead to loosening and failure. Maintaining proper torque wrench accuracy is crucial for safety and performance.

Can I calibrate my torque wrench at home?

While specialized tools and equipment are typically required for precise calibration, you can perform some basic checks at home. These checks will not provide accurate torque wrench accuracy, but can help assess the approximate wrench condition. If you suspect issues, it’s best to consult a professional calibration service.

What type of torque wrench is easiest to keep calibrated?

Beam-type torque wrenches tend to hold their calibration longer than click-type wrenches, as they have fewer moving parts. However, even beam-type wrenches require occasional checks and calibration to ensure optimal torque wrench accuracy over time.

So, there you have it! Hopefully, you’ve got a better grip on what affects torque wrench accuracy. Don’t skimp on calibration, and keep those fasteners tight!