Understanding structural integrity is paramount in civil engineering, especially when considering frameworks. Finite element analysis (FEA), a critical tool for engineers, simulates stress distribution within various structures, including trusses. The American Society of Civil Engineers (ASCE) provides essential standards and guidelines for safe and efficient construction using these designs. Exploring the Pratt truss, known for its efficient use of materials, reveals why optimized member arrangement is critical for achieving strongest truss designs. Examining case studies of bridge construction in locations like Switzerland, known for its mountainous terrain, highlights how effective implementation of these principles leads to enduring infrastructure.

Trusses stand as quintessential structural elements, their presence felt across a spectrum of engineering marvels. From the graceful arches of bridges that span vast distances to the sturdy frameworks supporting our roofs, trusses silently bear the weight of our built environment.

This intricate assembly of interconnected members exhibits a remarkable ability to redistribute forces, making it indispensable in construction and design. Their applications are incredibly diverse.

This article embarks on a journey to explore the realm of truss designs, focusing intently on identifying and ranking the strongest contenders. We will delve into their unique characteristics, dissect their load-bearing capabilities, and pinpoint their ideal applications.

Defining the Truss: The Cornerstone of Structural Integrity

At its core, a truss is an engineered structure comprised of interconnected members arranged in a geometric pattern, typically triangles. This arrangement is no accident; it’s the key to the truss’s exceptional strength and stability.

The primary function of a truss is to efficiently transfer loads from one point to another.

This transfer is achieved through tension and compression within its members. By distributing forces along these members, trusses minimize bending moments, a phenomenon that can weaken a structure. This makes them exceptionally efficient at spanning long distances while using minimal material.

The Imperative of Design: Strength Through Selection

Selecting the right truss design is paramount to ensuring the strength and long-term stability of any structure.

Each design possesses unique characteristics that make it suitable for specific applications and load conditions. A design ill-suited for its intended purpose can lead to structural deficiencies, increased maintenance costs, or, in the worst-case scenario, catastrophic failure.

Therefore, a thorough understanding of the strengths and weaknesses of different truss designs is crucial for engineers and builders alike.

A Glimpse at the Titans: Previewing Top Truss Designs

Prepare to explore a curated selection of the most robust and widely used truss designs in the field of structural engineering. Each design boasts a unique configuration, offering distinct advantages in terms of load-bearing capacity, material efficiency, and suitability for various applications.

Trusses stand as quintessential structural elements, their presence felt across a spectrum of engineering marvels. From the graceful arches of bridges that span vast distances to the sturdy frameworks supporting our roofs, trusses silently bear the weight of our built environment.

This intricate assembly of interconnected members exhibits a remarkable ability to redistribute forces, making it indispensable in construction and design. Their applications are incredibly diverse.

This article embarks on a journey to explore the realm of truss designs, focusing intently on identifying and ranking the strongest contenders. We will delve into their unique characteristics, dissect their load-bearing capabilities, and pinpoint their ideal applications.

Defining the Truss: The Cornerstone of Structural Integrity

At its core, a truss is an engineered structure comprised of interconnected members arranged in a geometric pattern, typically triangles. This arrangement is no accident; it’s the key to the truss’s exceptional strength and stability.

The primary function of a truss is to efficiently transfer loads from one point to another.

This transfer is achieved through tension and compression within its members. By distributing forces along these members, trusses minimize bending moments, a phenomenon that can weaken a structure. This makes them exceptionally efficient at spanning long distances while using minimal material.

The Imperative of Design: Strength Through Selection

Selecting the right truss design is paramount to ensuring the strength and long-term stability of any structure.

Each design possesses unique characteristics that make it suitable for specific applications and load conditions. A design ill-suited for its intended purpose can lead to catastrophic failure, underscoring the importance of understanding the fundamental principles that govern truss behavior.

Truss Fundamentals: Understanding the Building Blocks of Strength

Before delving into specific truss designs, it’s essential to grasp the underlying principles that dictate their strength and stability.

A truss isn’t just a collection of beams; it’s a carefully orchestrated system where each component plays a crucial role in distributing and managing loads.

Understanding these fundamentals is key to appreciating the nuances of different truss designs and their suitability for various applications.

Decoding the Anatomy of a Truss

A truss comprises three primary components, each contributing to its overall structural integrity:

-

Chords: These are the top and bottom horizontal members of the truss. Chords primarily resist bending forces, experiencing tension on one side and compression on the other. They define the overall shape and span of the truss.

-

Web Members: These are the diagonal and vertical members that connect the chords. Web members resist shear forces, preventing the chords from sliding relative to each other. They distribute the load throughout the truss, ensuring that no single point bears the brunt of the force.

-

Joints: These are the points where the members connect. Joints are critical for transferring forces between members. The design of the joints significantly impacts the truss’s overall strength and stability. They must be strong enough to withstand the forces acting upon them without failing.

Key Concepts in Truss Design

Several key concepts govern the behavior and strength of trusses. A thorough understanding of these concepts is crucial for designing safe and efficient structures:

-

Load-Bearing Capacity: This refers to the maximum load a truss can withstand before failure. It’s a critical parameter in structural design, ensuring that the truss can safely support the intended weight and forces.

-

Tensile Strength: This measures a material’s resistance to being pulled apart. Truss members in tension experience this force, and their tensile strength must be sufficient to prevent them from snapping under load.

-

Compressive Strength: This measures a material’s resistance to being crushed. Truss members in compression experience this force, and their compressive strength must be sufficient to prevent them from buckling or collapsing.

Potential Failure Modes

Understanding how trusses fail is just as important as understanding how they work. Two common failure modes are:

-

Buckling: This occurs when a compressive force causes a member to bend or deform suddenly. Buckling is often a concern for long, slender members that are not adequately supported.

-

Shear Stress: This is the force that causes layers of a material to slide past each other. Excessive shear stress can lead to the failure of joints or web members, compromising the truss’s overall integrity.

The Guiding Principles of Structural Engineering

The design and analysis of trusses are governed by fundamental principles of structural engineering, including:

-

Statics: This branch of mechanics deals with forces in equilibrium. Truss analysis relies heavily on statics to determine the forces acting on each member and ensure that the entire structure is stable.

-

Material Properties: Understanding the properties of the materials used in a truss, such as its modulus of elasticity, yield strength, and density, is crucial for accurate analysis and design.

-

Safety Factors: Structural engineers incorporate safety factors into their designs to account for uncertainties in loading conditions, material properties, and construction practices. Safety factors ensure that the truss can withstand loads significantly greater than its expected service load.

By understanding these fundamental principles and components, we can begin to appreciate the sophistication and efficiency of truss designs, paving the way for a deeper exploration of specific types and their applications.

The Strongest Contenders: A Deep Dive into Top Truss Designs

Having established the fundamental principles that govern truss behavior, we can now turn our attention to some of the most robust and widely used truss designs. Each of these designs offers a unique approach to load distribution and structural efficiency, making them suitable for a variety of applications. Understanding their specific strengths and weaknesses is crucial for selecting the optimal truss for a given project.

Warren Truss: Simplicity and Efficiency

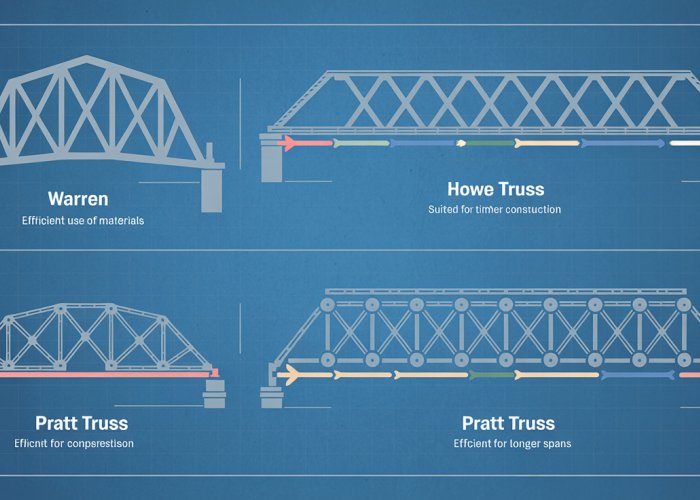

The Warren truss is instantly recognizable by its characteristic series of equilateral or isosceles triangles. This configuration, devoid of vertical members (in its simplest form), relies entirely on diagonal members to distribute loads.

Load Distribution and Efficiency

The beauty of the Warren truss lies in its efficient use of materials. The diagonal members alternately experience tension and compression as loads are applied, effectively distributing forces across the entire span. This even distribution minimizes stress concentrations and maximizes load-bearing capacity for a given amount of material.

Applications

Warren trusses find extensive use in bridges, particularly those with medium spans. Their simple geometry makes them relatively easy to fabricate and assemble, contributing to cost-effectiveness.

They are also commonly employed in roof structures, especially in industrial buildings and warehouses where large, open spans are required. The open web design allows for the easy integration of mechanical and electrical services.

Pratt Truss: Optimized for Tension

The Pratt truss is distinguished by its diagonal members, which slope downwards towards the center of the span. This seemingly simple design choice has profound implications for load distribution.

Tension vs. Compression

In a Pratt truss, vertical members are primarily subjected to compressive forces, while diagonal members are primarily subjected to tensile forces. This is a significant advantage, as steel (a common material for Pratt trusses) performs exceptionally well under tension. The diagonals effectively "pull" on the joints, counteracting the compressive forces in the verticals.

Applications

Pratt trusses are frequently used in bridges, particularly for longer spans where tensile strength is a critical factor. The efficient use of steel in tension allows for the creation of strong and lightweight structures capable of supporting heavy loads over considerable distances. They can also be found in large-span roofs and industrial buildings.

Howe Truss: A Historical Perspective

The Howe truss features diagonal members that slope upwards towards the center of the span, a configuration opposite that of the Pratt truss. While less common in modern construction using steel, the Howe truss holds historical significance.

Timber and Steel

Historically, Howe trusses were predominantly constructed from timber. The diagonals, being primarily in tension, were well-suited to the tensile strength of wood. However, the vertical members, experiencing compression, were often reinforced with steel to prevent buckling. This combination of materials reflected the limitations and strengths of available resources at the time.

Steel Trusses: The Strength of Alloy

Steel trusses represent a broad category, encompassing various truss designs (Warren, Pratt, Howe, etc.) constructed using steel as the primary material. The selection of steel unlocks a different level of strength properties when compared to wood-based builds.

Strength Properties

Steel offers superior tensile and compressive strength compared to wood. It also boasts a high strength-to-weight ratio, allowing for the construction of lighter and more efficient trusses. Steel’s ductility and resistance to deformation make it an ideal choice for demanding structural applications.

Wood Trusses: Sustainable and Versatile

Wood trusses are valued for their sustainability, cost-effectiveness, and aesthetic appeal. While not as strong as steel trusses, wood trusses offer a viable option for many residential and light commercial applications.

Strength Properties

The strength of a wood truss depends heavily on the species of wood used and the quality of the connections between members. Engineered wood products, such as laminated veneer lumber (LVL) and wood I-joists, can significantly enhance the strength and stiffness of wood trusses. Wood’s natural insulation properties also contribute to energy efficiency.

Material Selection: Optimizing Strength and Durability

Having explored some of the most effective truss designs, the next critical consideration is the selection of appropriate materials. The material used in truss construction has a profound impact on its strength, durability, longevity, and overall suitability for a given application. A seemingly perfect truss design can be rendered inadequate if constructed from a material that is not up to the task.

The Critical Impact of Material Choice

The material chosen for a truss dictates its performance in several key areas. Strength, both tensile and compressive, is paramount. The truss must be able to withstand the anticipated loads without yielding or fracturing. Stiffness is also crucial, as excessive deflection can compromise the integrity of the structure and its functionality.

Beyond pure mechanical properties, durability is essential for long-term performance. The material must resist degradation from environmental factors like moisture, temperature fluctuations, and chemical exposure. Weight is another important consideration, especially in applications where minimizing the overall load on the supporting structure is critical.

Comparing Steel, Wood, and Aluminum Trusses

Each of these materials offers a distinct set of advantages and disadvantages.

Steel Trusses

Steel is renowned for its high strength-to-weight ratio and exceptional durability. Steel trusses can handle significant loads and are resistant to fire, making them ideal for large-span structures like bridges and industrial buildings.

However, steel is susceptible to corrosion, especially in humid or marine environments. Protective coatings and regular maintenance are necessary to prevent rust and maintain structural integrity. Steel is also a relatively heavy material, which can increase transportation and installation costs.

Wood Trusses

Wood is a renewable and readily available material, making it a cost-effective option for many truss applications. Wood trusses are relatively lightweight and offer good insulation properties. They are also aesthetically pleasing and can be easily shaped and customized.

However, wood is susceptible to moisture damage, rot, and insect infestation. Preservative treatments are necessary to protect wood trusses from these threats. Wood is also less strong than steel, limiting its use in very large or heavily loaded structures. The strength of wood can vary significantly depending on the species, grade, and moisture content.

Aluminum Trusses

Aluminum offers an excellent strength-to-weight ratio and is highly resistant to corrosion. Aluminum trusses are lightweight and easy to transport and install. They are also non-magnetic and non-sparking, making them suitable for specialized applications.

However, aluminum is more expensive than steel or wood. It also has a lower modulus of elasticity than steel, meaning it is more prone to deflection under load. Aluminum is also susceptible to fatigue cracking under cyclic loading conditions.

Environmental Factors and Corrosion Resistance

The service environment plays a significant role in material selection. Structures in coastal areas require materials with high corrosion resistance, such as aluminum or galvanized steel.

In regions with extreme temperature fluctuations, materials with low thermal expansion coefficients are preferred to minimize stress build-up. In areas prone to seismic activity, materials with high ductility are essential to absorb energy and prevent catastrophic failure.

Choosing the right material involves a careful evaluation of these factors, along with consideration of cost, availability, and aesthetic requirements. Consulting with a structural engineer is highly recommended to ensure optimal material selection for your specific project.

Advanced Analysis: Leveraging FEA for Optimal Truss Design

Having established the importance of material selection in determining truss performance, it’s crucial to explore the analytical tools that enable engineers to push the boundaries of truss design. Advanced analysis techniques, particularly Finite Element Analysis (FEA), are indispensable for optimizing truss designs, ensuring structural integrity, and maximizing efficiency.

Understanding Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a powerful computational technique used to simulate the behavior of structures under various loading conditions.

It involves dividing a complex structure, like a truss, into smaller, discrete elements.

These elements are then analyzed individually, and their behavior is combined to predict the overall response of the structure.

This allows engineers to virtually test and refine designs before physical prototypes are even created, saving time and resources.

Predicting Stress Distribution and Structural Behavior

One of the key capabilities of FEA is its ability to predict stress distribution within a truss. By simulating the application of loads, FEA can identify areas of high stress concentration, revealing potential weak points in the design.

This information is invaluable for optimizing the geometry and material selection to ensure that the truss can withstand the anticipated forces.

Furthermore, FEA can simulate buckling behavior, a critical failure mode for slender truss members under compression. By identifying the critical buckling load, engineers can design truss members that are adequately braced and resistant to instability.

This predictive capability extends to overall load-bearing capacity, allowing engineers to determine the maximum load that a truss can safely support.

Optimizing Truss Designs for Maximum Efficiency and Safety

The benefits of using FEA for truss design optimization are numerous.

By accurately predicting stress distribution, buckling behavior, and load-bearing capacity, FEA allows engineers to fine-tune truss designs for maximum efficiency. This means achieving the desired strength and stiffness with the minimum amount of material, reducing weight and cost.

Moreover, FEA helps to ensure the safety and reliability of truss structures.

By identifying potential failure modes and weaknesses, engineers can implement design modifications to prevent catastrophic failures.

This is particularly important in critical applications such as bridges and buildings, where structural integrity is paramount.

Practical Applications of FEA in Truss Design

The practical applications of FEA in truss design are diverse and far-reaching. It’s used extensively in the design of bridges, allowing engineers to optimize the geometry and material selection for maximum load-carrying capacity and durability.

In the construction of buildings, FEA is used to ensure that roof trusses can withstand wind loads, snow loads, and other environmental factors.

FEA also plays a crucial role in the design of aerospace structures, where weight is a critical consideration. By optimizing truss designs using FEA, engineers can minimize the weight of aircraft and spacecraft without compromising structural integrity.

Having explored the analytical power of FEA in optimizing truss designs, the theoretical knowledge must now meet practical implementation. Examining real-world applications allows us to appreciate the strengths and limitations of different truss designs when subjected to the unpredictable demands of real-world projects. It’s within these case studies that we find the true testament to a truss’s effectiveness.

Real-World Applications: Case Studies of Strong Truss Designs in Action

The true measure of a truss design’s efficacy lies in its performance within real-world structures. By examining case studies of successful implementations, we can gain a deeper understanding of the benefits and challenges associated with each design.

These examples demonstrate the critical importance of selecting the right truss for a specific application.

Bridges: Warren and Pratt Trusses in Spanning Gaps

Bridges provide some of the most visually striking and structurally demanding applications of truss systems. The Warren truss, characterized by its diagonal members forming a series of equilateral or isosceles triangles, is often employed in shorter-span bridges.

Its simple geometry and efficient use of materials make it a cost-effective choice.

The Pit River Bridge: A Warren Truss Triumph

The Pit River Bridge in California stands as an iconic example. Its Warren truss design is well-suited for handling the tensile and compressive forces generated by traffic loads across a moderate span.

However, Warren trusses can become less economical for very long spans due to the increasing weight of the truss itself.

For longer spans, the Pratt truss often emerges as the preferred choice. This design utilizes vertical members to resist compression and diagonal members to resist tension. This configuration proves particularly efficient in handling the bending moments and shear forces associated with longer spans.

The Forth Bridge: A Pratt Truss Masterpiece

The Forth Bridge in Scotland, a UNESCO World Heritage Site, is a quintessential example of a Pratt truss bridge. Its design excels at distributing loads efficiently across its immense span.

The strategic arrangement of its members allows for the use of relatively lightweight materials while maintaining exceptional strength and stability. The size and scale demonstrate the long-term utility and durability of the design.

Roofs: Howe and Fan Trusses in Enclosing Spaces

Trusses are equally crucial in roof construction, where they provide long-span support for a variety of building types. The Howe truss, distinguished by its diagonal members sloping upwards towards the center, was historically favored for timber bridges.

Modern applications often incorporate steel for the vertical members to enhance strength and durability.

Industrial Warehouses: A Howe Truss Workhorse

Howe trusses are frequently used in industrial warehouses and large commercial buildings. Their simple design and ease of fabrication make them a cost-effective solution for supporting large roof spans.

However, the specific geometry of the Howe truss may not be optimal for all roof shapes or loading conditions.

For complex roof geometries or situations requiring minimal internal supports, the fan truss offers a viable alternative.

Aircraft Hangers: Fan Trusses for Clear Spans

Fan trusses, with their radiating web members, are often used in structures like aircraft hangars and sports arenas. Their design allows for clear, unobstructed spans. This is ideal for accommodating large equipment or maximizing usable space.

The increased number of web members, however, can add to the overall cost and complexity of fabrication.

The Role of Material Selection: A Comparative Analysis

The choice of material significantly impacts the performance and longevity of truss structures. Steel trusses offer high strength-to-weight ratios and excellent resistance to tension and compression. This makes them ideal for bridges, high-rise buildings, and other demanding applications.

However, steel is susceptible to corrosion. It requires protective coatings and regular maintenance.

Wood trusses, while offering a lower strength-to-weight ratio compared to steel, provide a sustainable and aesthetically pleasing option for residential and light commercial construction. Wood is also naturally resistant to corrosion, but it is vulnerable to moisture, insects, and fire.

Careful treatment and design considerations are necessary to mitigate these risks.

Challenges and Considerations

While truss designs offer numerous advantages, it’s crucial to acknowledge potential challenges:

- Complex Loadings: Real-world structures are often subjected to complex and unpredictable loading conditions, including wind loads, seismic forces, and dynamic loads from moving vehicles or equipment.

- Environmental Factors: Exposure to harsh environmental conditions, such as extreme temperatures, humidity, and corrosive substances, can degrade truss materials over time, compromising their structural integrity.

- Maintenance and Inspection: Regular maintenance and inspection are essential for identifying and addressing potential problems, such as corrosion, cracking, or loose connections.

By carefully considering these challenges and implementing appropriate design and maintenance strategies, engineers can ensure the long-term safety and reliability of truss structures.

FAQs: Truss Design for Ultimate Strength

Here are some frequently asked questions about truss designs and how they achieve maximum strength.

What makes a truss design strong?

A strong truss design efficiently distributes weight and force. This is accomplished by arranging members in a triangular pattern, minimizing bending stresses and maximizing tensile and compressive forces. The best designs avoid long, unsupported spans.

Which truss design is generally considered the strongest?

While the "strongest" depends on specific loading and span conditions, the Warren truss and Howe truss are often cited for their strength-to-weight ratio. These strongest truss designs are efficient at handling various load types.

How does material choice impact truss strength?

The material used significantly affects the overall strength of a truss. High-strength steel or engineered wood products are commonly chosen for their ability to withstand high tensile and compressive forces. Proper material selection is crucial for building the strongest truss designs.

What factors should I consider when selecting a truss design?

Consider the span length, load type (static vs. dynamic), environmental factors (wind, snow), and available materials. Consulting with a structural engineer is recommended to ensure you select the most appropriate and strongest truss design for your specific application.

Alright, that’s a wrap on strongest truss designs! Hopefully, you’ve got some solid ideas to build on. Go forth and engineer something awesome!