Stained pine wood projects often begin with careful surface preparation. Minwax, a leading wood finishing product, provides various stains tailored for pine. Understanding the wood grain is crucial for achieving optimal stain absorption. Furthermore, furniture makers are increasingly utilizing stained pine wood because its affordability and aesthetic appeal.

Unlocking the Beauty of Stained Pine Wood

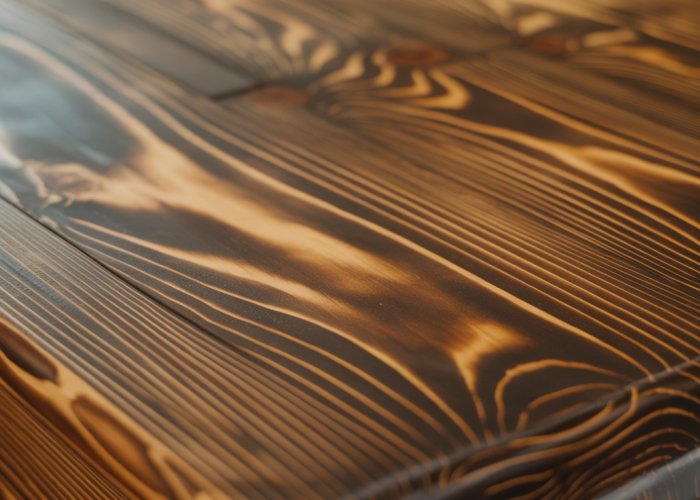

Pine wood, with its readily available nature and light color, has long been a favorite among both seasoned woodworkers and DIY enthusiasts. Its versatility lends itself well to a variety of projects, from rustic furniture to charming home décor.

But it’s the ability to transform pine through staining that truly unlocks its potential, elevating it from a simple building material to a piece of art.

The Allure of Pine

Pine’s appeal lies in several key characteristics. Its light hue provides a blank canvas for a wide range of stain colors, allowing you to achieve the desired aesthetic for your project. The distinctive grain pattern, often featuring prominent knots, adds character and visual interest, especially when enhanced by a well-chosen stain.

Moreover, pine is a relatively soft wood, making it easier to work with than hardwoods like oak or maple. This ease of use makes it an excellent choice for beginners looking to develop their woodworking skills. Its affordability compared to other wood types also makes it an attractive option for projects on a budget.

Why Stain Pine? Aesthetics and Protection

Staining pine goes beyond simply changing its color. It’s about enhancing its natural beauty and providing crucial protection.

A carefully selected stain can accentuate the grain pattern, bringing out the wood’s unique character and creating a richer, more visually appealing surface. Staining allows you to customize the color to match your existing décor or achieve a specific design aesthetic.

Beyond aesthetics, staining offers a layer of protection against moisture, scratches, and UV damage. The stain penetrates the wood fibers, helping to seal them and prevent them from absorbing moisture, which can lead to warping, cracking, or rot. Pigmented stains also offer some degree of UV protection, preventing the wood from fading or discoloring over time.

Your Guide to Staining Pine: Achieving Professional Results

This guide aims to empower you with the knowledge and techniques to achieve professional-looking results when staining pine wood. Whether you’re a seasoned woodworker or a complete beginner, we’ll walk you through every step of the process, from preparing the wood to applying the final finish.

We’ll cover everything from selecting the right stain and tools to mastering essential application techniques.

Our goal is to provide you with a complete, accessible, and easy-to-follow tutorial that will enable you to transform ordinary pine into stunning, durable, and personalized pieces. Let’s embark on this journey and unlock the beauty of stained pine wood together.

Staining allows you to customize the color to match your existing décor or achieve a specific design aesthetic.

Beyond aesthetics, staining offers protection against moisture, UV damage, and everyday wear and tear. This is especially important for pine, which is a relatively soft wood and can be susceptible to scratches and dents. Staining, followed by a protective finish, helps to extend the lifespan of your project and keep it looking beautiful for years to come.

Understanding Pine Wood: Characteristics and Considerations

Before diving into the staining process, it’s crucial to understand the unique characteristics of pine wood. Its inherent properties will influence how it accepts stain and ultimately affect the final outcome of your project.

Pine Wood’s Physical Properties

Pine is a softwood characterized by its:

- Light color: Ranging from creamy white to pale yellow, making it an excellent base for various stain colors.

- Prominent grain pattern: Often featuring distinct knots, adding character and visual interest. The grain can vary from straight to slightly wavy, influencing stain absorption.

- Softness: This makes it easy to work with but also more prone to dents and scratches. Proper surface preparation and protective finishes are essential.

The Pros and Cons of Staining Pine

Pine’s popularity as a staining choice stems from several advantages:

- Cost-effectiveness: Compared to hardwoods, pine is significantly more affordable, making it ideal for budget-conscious projects.

- Widespread availability: Pine is readily available at most lumberyards and home improvement stores, simplifying material sourcing.

- Ease of workability: Its softness allows for easier cutting, shaping, and sanding, making it beginner-friendly.

However, staining pine presents certain challenges:

- Uneven absorption: Due to varying densities within the wood, stain can be absorbed unevenly, leading to blotching. This is especially noticeable around knots and areas with tighter grain.

- Blotching: This is the most common complaint when staining pine. It appears as dark, uneven patches on the surface, detracting from the desired finish.

Mitigating Staining Issues

Fortunately, there are effective methods to overcome these challenges:

- Pre-stain wood conditioner: This is the most crucial step in preventing blotching. It seals the wood pores, promoting more even stain absorption.

- Proper sanding: Thorough sanding with progressively finer grits creates a smooth, uniform surface, improving stain penetration.

- Choosing the right stain: Gel stains are formulated to sit on the surface of the wood, minimizing penetration and reducing blotching.

- Applying thin coats: Multiple thin coats of stain are better than one thick coat. This allows for better control over the color intensity and reduces the risk of uneven absorption.

- Wiping the stain: Wiping the stain after a few minutes removes excess stain and helps to even out the color.

Preparing the Pine Wood: The Foundation for a Flawless Finish

A truly exceptional stained finish begins long before you open the can of stain. Wood preparation is paramount, representing the essential groundwork upon which the final beauty of your project will be built. Rushing this stage invariably leads to imperfections that detract from the overall result.

The Indispensable Role of Sanding

Sanding is the cornerstone of proper wood preparation. It creates a smooth, uniform surface, free from imperfections that could hinder stain absorption.

Grit Progression: From Coarse to Fine

Achieving a flawless surface involves a strategic approach to sanding, utilizing a grit progression. Start with a coarser grit sandpaper (e.g., 80-120) to remove any existing imperfections like scratches, dents, or mill marks.

After addressing initial flaws, transition to progressively finer grits. A typical progression might include 150-grit, followed by 180-grit, and finally, 220-grit sandpaper. This step-by-step approach gradually refines the surface, ensuring optimal smoothness for stain application.

Effective Sanding Techniques

Consistent sanding is key. Sand with the grain to avoid creating unsightly scratches that run perpendicular to the wood’s natural pattern.

Apply moderate, even pressure, avoiding excessive force that could cause uneven sanding. Overlap each pass slightly to ensure complete coverage.

For flat surfaces, a sanding block or orbital sander can help maintain even pressure and prevent gouging. On contoured or detailed areas, hand-sanding may be necessary to reach every nook and cranny.

Cleaning: Removing the Dust of Creation

Sanding inevitably creates dust, which, if left on the surface, can interfere with stain adhesion and create a muddy or uneven finish. Thorough cleaning is therefore crucial.

The Magic of Tack Cloth

A tack cloth is a slightly sticky cheesecloth designed to lift and trap dust particles. Gently wipe the entire sanded surface with the tack cloth, ensuring you cover every area. Replace the cloth when it becomes saturated with dust.

Alternative Cleaning Methods

If you don’t have a tack cloth, several alternatives can work. A slightly damp (not wet!) lint-free cloth can effectively remove dust. Ensure the cloth is clean and wrung out thoroughly to prevent raising the wood grain.

A vacuum cleaner with a soft brush attachment can also be used to remove loose dust particles. Always follow up with a tack cloth or damp cloth to remove any remaining residue.

Pre-Stain Wood Conditioner: Taming Pine’s Thirst

Pine, being a softwood, is notorious for its tendency to absorb stain unevenly, resulting in blotching. Pre-stain wood conditioner is the secret weapon in achieving a uniform, professional-looking finish on pine.

Preventing Blotching: How it Works

Pre-stain conditioner works by partially sealing the wood pores, reducing the amount of stain the wood can absorb. This creates a more consistent base for the stain, minimizing blotching and ensuring even color distribution.

Application Instructions

Apply the pre-stain wood conditioner liberally with a brush or rag, following the manufacturer’s instructions. Allow it to penetrate the wood for the recommended time, typically 5-15 minutes.

Wipe off any excess conditioner with a clean cloth before it dries completely. Proceed with staining within the timeframe specified by the conditioner’s manufacturer, usually within a couple of hours.

By meticulously preparing the pine wood, you set the stage for a stunning, long-lasting stained finish that showcases the wood’s natural beauty while adding character and value to your project.

Choosing the Right Wood Stain: Color and Type

With a freshly prepared surface, the exciting stage of selecting the perfect stain arrives. The array of wood stain options available can feel overwhelming, but understanding the nuances of each type and color will empower you to make an informed decision that aligns with your creative vision and project requirements.

Navigating the Spectrum of Wood Stain Options

The world of wood stains is vast, offering a diverse palette of colors, formulations, and performance characteristics. From traditional oil-based stains to modern water-based alternatives and specialized gel stains, each possesses unique properties that cater to different needs and preferences.

Types of Wood Stain: A Comparative Analysis

Selecting the right type of wood stain is crucial for achieving the desired aesthetic and ensuring long-lasting results. Let’s delve into the characteristics of the three primary types: oil-based, water-based, and gel stains.

Oil-Based Stains: Richness and Grain Enhancement

Oil-based stains are renowned for their ability to penetrate deeply into the wood grain, imparting a rich, vibrant color and accentuating the natural beauty of the wood. They offer excellent color saturation and tend to provide a warmer, more traditional look.

These stains are particularly effective at enhancing the grain pattern, creating depth and dimension in the wood. They are often preferred for projects where highlighting the natural character of the wood is a priority.

Oil-based stains typically have a longer drying time compared to water-based alternatives, and require mineral spirits for cleanup. Proper ventilation is essential during application and drying due to the presence of volatile organic compounds (VOCs).

Water-Based Stains: Eco-Friendly and User-Friendly

Water-based stains have gained popularity in recent years due to their low VOC content, making them a more environmentally friendly choice. They offer easy cleanup with soap and water and often dry faster than oil-based stains.

While water-based stains may not penetrate the wood as deeply as oil-based options, they still provide excellent color and clarity. They tend to produce a more even, uniform color, which can be advantageous for achieving a contemporary look.

They are less likely to raise the wood grain compared to oil-based stains, reducing the need for extensive sanding between coats. This makes them a convenient option for beginners and those seeking a quicker finishing process.

Gel Stains: Versatility for Challenging Surfaces

Gel stains are characterized by their thick, gel-like consistency, which makes them ideal for vertical surfaces, fiberglass, metal, and even previously finished wood.

They excel at providing uniform color coverage on uneven or non-porous surfaces where traditional stains may struggle to adhere properly.

Gel stains do not penetrate the wood grain in the same way as oil-based or water-based stains. Instead, they create a layer of color on the surface. This makes them a great choice for achieving a consistent look across different materials or covering imperfections in the wood.

Color Selection: Harmonizing with Wood Tone and Project Goals

Choosing the right stain color is a pivotal step in the staining process, requiring careful consideration of the existing wood tone and the overall aesthetic you wish to achieve.

Considering the Existing Wood Tone

The natural color of the pine wood will influence the final appearance of the stain. Lighter stains will allow more of the wood’s natural color to show through, while darker stains will mask the underlying tone.

It’s crucial to select a stain color that complements the wood’s inherent warmth or coolness.

Aligning with Project Goals

The stain color should also align with the intended use and style of the project. For example, a rustic farmhouse table might benefit from a weathered gray or dark brown stain, while a modern coffee table could showcase a lighter, more natural finish.

Consider the surrounding décor and furniture in the room to ensure that the stained wood complements the overall aesthetic.

The Importance of Testing Colors

Always test the stain color on a scrap piece of pine before applying it to the entire project. This allows you to visualize the final result and make adjustments as needed.

Apply the stain to the test piece using the same technique you plan to use on the project, and allow it to dry completely before evaluating the color. Testing will save time and prevent potential disappointment.

Popular Wood Stain Brands: A Trusted Selection

Several reputable brands offer a wide range of high-quality wood stains. Here are a few popular choices:

- Minwax: A well-known brand offering a diverse selection of stains in various colors and formulations.

- Rust-Oleum: Renowned for its durable and long-lasting stains, suitable for both interior and exterior projects.

- Varathane: Offers premium stains with exceptional clarity and fade resistance, providing a professional-grade finish.

With the wood prepped and your stain selected, it’s time to bring your vision to life. The actual application of the stain is where the project truly takes shape, transforming bare pine into a work of art. Mastering the techniques and understanding the nuances of application will ensure a professional, even, and beautiful finish.

Applying the Wood Stain: A Step-by-Step Guide

The moment of truth has arrived: applying the wood stain. This stage demands patience, precision, and a keen eye for detail. By following these steps and mastering the techniques, you’ll be well on your way to achieving a stunning, professional-quality finish on your pine wood project.

Gathering Essential Tools and Materials

Before you even crack open the can of stain, ensure you have everything you need within arm’s reach. A well-prepared workspace translates to a smoother, more efficient staining process. Here’s a checklist of essential items:

- Wood stain of your chosen color and type.

- Application tools: High-quality brushes (natural or synthetic, depending on the stain), foam brushes, paint sprayer (optional).

- Clean, lint-free rags or cloths.

- Paint tray or container.

- Stir sticks.

- Gloves to protect your hands.

- Safety glasses.

- Respirator or mask, especially when working with oil-based stains.

- Mineral spirits or water (depending on the type of stain) for cleanup.

- Drop cloths or plastic sheeting to protect your work surface.

- Good lighting to ensure even application.

Application Techniques: Mastering the Methods

The way you apply the stain significantly impacts the final result. There are three primary techniques: brushing, spraying, and wiping. Each offers unique advantages and is suited for different project types and desired effects.

Brushing for a Smooth Coat

Brushing is a classic and versatile method, ideal for smaller projects and detailed work.

Choose a high-quality brush appropriate for the type of stain you’re using (natural bristles for oil-based, synthetic for water-based). Dip the brush into the stain, removing any excess against the side of the can or tray. Apply the stain in smooth, even strokes, following the direction of the wood grain. Avoid applying too much pressure, which can lead to drips and uneven coverage. Overlap each stroke slightly to ensure consistent color.

Spraying for Large Areas

Spraying is an excellent option for larger surfaces, intricate designs, or when you want to achieve a very even, consistent color.

Use a paint sprayer designed for stains (HVLP sprayers are often recommended). Thin the stain according to the manufacturer’s instructions. Practice your spraying technique on a piece of scrap wood to get a feel for the sprayer and ensure even coverage. Apply the stain in light, overlapping coats, holding the sprayer at a consistent distance from the surface. Avoid spraying too much stain in one area, which can lead to runs and drips.

Wiping for Grain Enhancement

Wiping is a technique used to enhance the grain pattern of the wood and achieve a more rustic or textured look.

Apply the stain liberally with a brush or rag. Allow the stain to sit on the surface for a few minutes to penetrate the wood. Then, use a clean, lint-free rag to wipe off the excess stain, working in the direction of the grain. The longer you leave the stain on before wiping, the darker the color will be. This method is great for accentuating the natural beauty of pine wood.

Detailing the Staining Process: Thin Coats and Excess Removal

Regardless of the application technique you choose, the key to a flawless finish lies in applying thin, even coats and diligently wiping off any excess stain.

Applying Thin Coats

Resist the temptation to apply a thick coat of stain, hoping to achieve the desired color in one go. Multiple thin coats are always better than one thick coat. Thin coats allow the wood to absorb the stain evenly, preventing blotching and ensuring a consistent color throughout the project.

Wiping Excess Stain

After applying the stain, allow it to penetrate the wood for the recommended time (usually a few minutes, check the stain manufacturer’s instructions). Then, use a clean, lint-free rag to wipe off any excess stain, working in the direction of the grain. This step is crucial for preventing a sticky or uneven finish. It also allows you to control the final color intensity; the more stain you wipe off, the lighter the color will be.

Discussing Drying Time: Factors and Acceleration

Patience is a virtue when it comes to staining wood. Allowing the stain to dry completely is essential for a durable and beautiful finish.

Factors Affecting Drying Time

Several factors influence the drying time of wood stain, including:

- Type of stain (oil-based stains generally take longer to dry than water-based stains).

- Humidity levels (high humidity can significantly slow down drying).

- Temperature (warmer temperatures promote faster drying).

- Ventilation (good ventilation helps the stain to dry more quickly).

- The number of coats applied.

Tips for Faster Drying

While you can’t control the weather, you can take steps to accelerate the drying process:

- Ensure good ventilation in your workspace. Open windows and use fans to circulate air.

- Maintain a warm temperature in the room.

- Use a dehumidifier to reduce humidity levels.

- Apply thin coats of stain, allowing each coat to dry completely before applying the next.

- Consider using a stain with a faster drying time, such as a water-based stain.

By carefully considering these factors and implementing these tips, you can minimize drying time and keep your project moving forward.

With the wood now beautifully stained, the next critical phase is preserving and enhancing your work. This involves two key steps: sealing and finishing. Sealing protects the stained wood from moisture and wear, while finishing adds a final layer of beauty and durability.

Sealing and Finishing: Protecting and Enhancing Your Work

Sealing and finishing are arguably as crucial as the staining process itself. They are what truly lock in your hard work, providing a protective barrier against the elements and daily wear and tear. Without these steps, your stained pine wood is vulnerable to damage and the color will fade over time.

The Importance of Sealing

Sealing your stained pine is non-negotiable if you want a long-lasting, beautiful finish. A sealer acts as a protective shield, preventing moisture from penetrating the wood and causing warping, swelling, or even rot.

It also helps to prevent the stain from fading or discoloring over time due to exposure to sunlight and other environmental factors. Think of it as an investment in the longevity of your project.

Types of Sealers

Choosing the right sealer depends on the type of stain you used and the intended use of the project. Here are some common options:

-

Shellac: A natural resin sealer that provides a good moisture barrier and enhances the wood’s natural color. It’s easy to apply and dries quickly but is not as durable as other options.

-

Lacquer: A fast-drying sealer that provides a smooth, durable finish. It’s available in different sheens, from matte to high gloss. However, lacquer can be brittle and prone to cracking in humid environments.

-

Polyurethane: A synthetic sealer known for its exceptional durability and resistance to water, chemicals, and abrasion. It’s a great choice for high-traffic areas or projects that will be exposed to moisture. Polyurethane is available in both oil-based and water-based formulas.

Understanding Finishing

Finishing takes the protection and aesthetics a step further. It involves applying a topcoat that not only adds another layer of protection but also enhances the overall look and feel of the wood.

The finish coat determines the final sheen (gloss, semi-gloss, satin, or matte) and contributes significantly to the wood’s resistance to scratches, dents, and stains.

Finishing Options: Choosing the Right Topcoat

Selecting the appropriate finish is crucial for achieving the desired aesthetic and durability. Consider the following options:

-

Polyurethane: As mentioned earlier, polyurethane is a durable option for both sealing and finishing. It provides excellent protection against moisture, chemicals, and abrasion, making it ideal for tabletops, floors, and other high-use surfaces.

-

Varnish: A traditional finish that offers good protection and a warm, amber-like glow. It’s more flexible than lacquer, making it less prone to cracking. Varnish is available in oil-based and water-based formulations.

-

Lacquer: A fast-drying finish that provides a smooth, clear coat. It’s often used for furniture and musical instruments. However, as mentioned earlier, lacquer is not as durable as polyurethane or varnish and may not be suitable for high-moisture environments.

Step-by-Step Finishing Guide

Follow these steps for a professional-looking finish:

-

Prepare the surface: Ensure the sealed surface is clean, dry, and free of dust or debris. Lightly sand with fine-grit sandpaper (220-grit or higher) to create a smooth surface for the finish to adhere to.

-

Apply the finish: Apply the finish in thin, even coats using a high-quality brush, foam applicator, or spray gun. Follow the manufacturer’s instructions for application techniques and drying times.

-

Allow to dry: Let each coat dry completely before applying the next. Drying times vary depending on the type of finish and environmental conditions (temperature and humidity).

-

Sand lightly between coats (optional): After each coat is dry, lightly sand with fine-grit sandpaper to remove any imperfections or brush marks. This will help to create a smoother, more professional-looking finish.

-

Apply additional coats: Apply two to three coats of finish for optimal protection and durability.

The Importance of Light Sanding Between Coats

Lightly sanding between coats of sealer or finish is a step often overlooked, but it makes a significant difference in the final outcome. This process, known as de-nibbing, involves using fine-grit sandpaper (typically 320-grit or higher) to gently smooth out any imperfections, dust particles, or raised grain that may have occurred during the drying process.

Safety Precautions: Prioritizing a Safe Staining Environment

With your wood now beautifully stained, protected and enhanced, remember that achieving a professional finish shouldn’t come at the expense of your well-being. Staining and finishing involve chemicals that can be harmful if not handled correctly. Therefore, understanding and implementing appropriate safety measures is paramount. Creating a safe working environment isn’t just a recommendation; it’s an essential part of the process.

Why Safety Matters

Safety is not merely a formality; it’s an integral component of any successful staining project. The products used in wood staining, such as stains, sealers, and finishes, often contain volatile organic compounds (VOCs) and other chemicals that can pose health risks if inhaled or absorbed through the skin. Ignoring safety precautions can lead to respiratory problems, skin irritation, and even long-term health issues.

Taking the time to implement safety measures ensures not only your well-being but also the quality of your work. A clear mind and healthy body allow you to focus on the task at hand, resulting in a better finish and a more enjoyable experience.

Ensuring Proper Ventilation

Proper ventilation is arguably the most crucial safety measure when working with wood stains and finishes. VOCs released during application and drying can accumulate in enclosed spaces, leading to dizziness, headaches, and nausea. Long-term exposure can have more severe health consequences.

Here’s how to ensure adequate ventilation:

- Work Outdoors: Whenever possible, move your project to an open, well-ventilated outdoor area. This allows fumes to dissipate naturally.

- Open Windows and Doors: If working indoors is unavoidable, open as many windows and doors as possible to create cross-ventilation.

- Use Fans: Strategically place fans to circulate air and exhaust fumes away from your work area. A window fan can be particularly effective in drawing out contaminated air.

- Consider a Respirator: For prolonged or intensive staining sessions, consider using a respirator with organic vapor cartridges (more on this below).

Essential Protective Gear

Beyond ventilation, wearing the right protective gear minimizes direct contact with harmful chemicals. Here’s a breakdown of essential items:

Gloves

- Chemical-Resistant Gloves: Always wear gloves made of nitrile or neoprene to protect your skin from stains, sealers, and solvents. Latex gloves are generally not suitable, as they can degrade upon contact with certain chemicals. Ensure the gloves fit properly and cover your wrists.

Masks and Respirators

-

Dust Mask (for Sanding): When sanding, wear a dust mask to prevent inhalation of fine wood particles.

-

Respirator (for Staining): When applying stains, sealers, or finishes, use a respirator equipped with organic vapor cartridges. These cartridges filter out harmful VOCs, protecting your respiratory system. Ensure the respirator fits snugly and is properly sealed to your face. Replace cartridges regularly, following the manufacturer’s recommendations.

Eye Protection

- Safety Glasses or Goggles: Protect your eyes from splashes and fumes by wearing safety glasses or goggles. Choose eyewear that provides a snug fit and offers side protection.

Clothing

- Wear appropriate clothing: Long sleeves and pants can minimize skin exposure. Consider wearing a disposable apron or coveralls for added protection.

Safe Disposal of Materials

Proper disposal of staining materials is crucial to prevent environmental contamination and potential hazards.

Here’s a guide:

- Stain-Soaked Rags: Oily rags can spontaneously combust. After use, spread them out flat in a well-ventilated area to dry completely before disposing of them in a metal container with a tight-fitting lid. Alternatively, soak the rags in water and seal them in a plastic bag before disposal.

- Empty Containers: Check the product label for specific disposal instructions. Many containers can be disposed of in regular trash after being completely emptied and dried.

- Leftover Stain or Finish: Do not pour leftover stain or finish down the drain. Instead, allow it to dry completely in the container before disposing of it. For larger quantities, contact your local waste management authority for guidance on proper disposal methods.

- Solvents and Cleaners: Dispose of solvents and cleaners according to local regulations. Many communities offer hazardous waste collection programs for these materials. Never pour solvents down the drain or onto the ground.

With the careful preparation, application, and finishing touches now behind you, it’s tempting to admire your newly stained pine wood. However, even with meticulous work, staining can sometimes present challenges. Recognizing and addressing these common issues is key to achieving a truly professional result.

Troubleshooting Common Staining Problems: Solutions and Prevention

No matter how carefully you prepare and apply your stain, issues can sometimes arise. Understanding these common problems and knowing how to address them can save your project and ensure a beautiful, lasting finish. Prevention, of course, is always the best strategy, but knowing how to correct mistakes is equally important.

Identifying Common Staining Issues

Before diving into solutions, it’s helpful to identify the most frequent culprits behind staining imperfections. These include:

-

Uneven stain absorption, resulting in a patchy or inconsistent color.

-

Blotching, where certain areas of the wood absorb too much stain, creating dark, unsightly spots.

-

Runs and drips, often occurring on vertical surfaces or in corners, leaving visible imperfections.

Uneven Stain Absorption: Diagnosing and Resolving

Uneven stain absorption is a common frustration when working with pine, often resulting in a blotchy or inconsistent finish. This typically occurs when some areas of the wood are more porous than others, leading to variations in stain uptake.

Identifying the Cause

Start by examining the wood surface closely. Are there areas that appear denser or smoother than others? These variations can affect how the stain penetrates the wood.

Addressing Uneven Absorption

Several strategies can help mitigate uneven stain absorption:

-

Pre-Stain Wood Conditioner: As previously discussed, this product is crucial for pine. It seals the wood’s pores, creating a more uniform surface for the stain to adhere to. Apply it evenly and allow it to dry according to the manufacturer’s instructions before staining.

-

Multiple Thin Coats: Instead of applying one thick coat of stain, opt for several thin coats, allowing each coat to dry partially before applying the next. This allows for more even penetration and color build-up.

-

Sanding: Lightly sanding the stained surface with a fine-grit sandpaper (220 or higher) after the first coat can help even out the color. Be careful not to sand through the stain entirely.

-

Gel Stain: Gel stains sit on top of the wood surface rather than penetrating deeply. This can minimize the impact of varying porosity and lead to a more even color.

Blotching: Prevention and Correction

Blotching is perhaps the most dreaded staining problem, especially with softwoods like pine. It manifests as dark, irregular patches where the wood has absorbed an excessive amount of stain.

Preventing Blotching

Prevention is key when it comes to blotching:

-

Pre-Stain Conditioner is Essential: Again, a pre-stain wood conditioner is your best defense. It reduces the wood’s absorbency, preventing excessive stain uptake.

-

Sanding Thoroughly: Ensure the wood is sanded evenly and smoothly, paying particular attention to areas around knots and end grain, which tend to absorb more stain.

-

Avoid Over-Application: Apply the stain in thin, even coats, and wipe off any excess promptly. Don’t allow the stain to pool or sit on the surface for extended periods.

Correcting Existing Blotches

If blotching has already occurred, don’t despair. Here are some corrective measures:

-

Mineral Spirits or Paint Thinner: Dampen a clean cloth with mineral spirits or paint thinner and gently rub the blotchy areas. This can help lift some of the excess stain. Be careful not to remove too much stain, which will result in an inconsistent finish.

-

Re-sanding: In severe cases, you may need to re-sand the affected areas and re-apply the stain. Start with a medium-grit sandpaper (120-150) and gradually move to a finer grit (220 or higher).

-

Applying a Toner: A toner is a diluted mixture of stain and finish that can be sprayed or wiped over the entire surface to even out the color. This is a more advanced technique, so practice on a scrap piece of wood first.

Runs and Drips: Eliminating Imperfections

Runs and drips are most common when staining vertical surfaces or intricate details. These imperfections occur when excess stain accumulates and flows downwards, creating unsightly streaks.

Preventing Runs and Drips

-

Apply Stain Sparingly: Use a brush or cloth to apply the stain in thin, even coats. Avoid overloading the applicator with stain.

-

Work in Sections: When staining vertical surfaces, work in small sections at a time, wiping off any excess stain immediately.

-

Check for Accumulation: Regularly inspect the surface for any signs of pooling or dripping, and address them promptly.

Correcting Runs and Drips

-

Wipe Immediately: If you notice a run or drip while the stain is still wet, wipe it away immediately with a clean cloth.

-

Sand When Dry: If the stain has dried, carefully sand the affected area with fine-grit sandpaper (220 or higher) to remove the imperfection. Be careful not to sand through the surrounding stain.

-

Feather the Edges: After sanding, feather the edges of the repaired area by lightly sanding outwards to blend it with the surrounding finish. Then, re-apply stain to the area, blending it carefully.

By understanding the causes of these common staining problems and implementing the appropriate prevention and correction techniques, you can achieve a flawless, professional-looking finish on your pine wood project. Remember to always test your solutions on a small, inconspicuous area first to ensure compatibility and desired results.

FAQs About Stained Pine Wood

Here are some frequently asked questions about working with and understanding stained pine wood, based on our ultimate guide. We hope these answers clarify any lingering questions you might have!

What makes pine wood a good option for staining?

Pine is a softwood, making it relatively easy to work with and readily accepts stain. Its porous nature allows the stain to penetrate, highlighting the wood’s grain. However, this also means it can be prone to blotching, so proper preparation is key to achieving an even, beautiful stained pine wood finish.

Why is a wood conditioner often recommended before staining pine?

Pine wood’s uneven density can lead to uneven stain absorption. A wood conditioner helps to pre-seal the wood, creating a more uniform surface. This allows the stained pine wood to absorb the stain more evenly, preventing blotchiness and ensuring a consistent color.

What types of stains work best on pine?

Both oil-based and water-based stains can be used on pine, but each offers different advantages. Oil-based stains tend to highlight the grain more and offer longer working times, while water-based stains dry faster and are easier to clean up. Ultimately, the best choice depends on the desired look and your personal preference for working with stained pine wood.

How can I prevent blotching when staining pine wood?

Proper surface preparation is crucial. Sand the wood smoothly, use a wood conditioner as recommended, and apply the stain in thin, even coats. Wiping off excess stain promptly also helps to prevent blotching and ensure a consistent, beautiful finish on your stained pine wood project.

So, what do you think about working with stained pine wood now? Hope this helps you nail your next project! Let me know if you have any questions. Happy staining!