Rubber stress strain, a critical concept in material science, directly influences the performance of numerous applications, including those involving Goodyear Tire & Rubber Company. Finite Element Analysis (FEA) provides valuable tools for predicting rubber stress strain under various loading conditions. The behavior observed and modeled with these tools allows Engineers specializing in Polymer Science to have a full understanding of the products they design. These behaviors under stress strain are often visualized using Stress-Strain Curves, which provide a graphical representation of the material’s response to applied force.

Optimizing Your Article Layout: "Rubber Stress Strain: The Ultimate Guide You Need Now!"

To effectively present "Rubber Stress Strain: The Ultimate Guide You Need Now!", a comprehensive and well-structured layout is crucial. The aim is to educate the reader on the core principles of "rubber stress strain" while maintaining clarity and engagement. Below outlines an optimal structure to achieve this.

1. Introduction: Defining Rubber Stress Strain

The introduction should immediately address the topic and its importance.

- Start with a captivating opening sentence to grab the reader’s attention (e.g., "Understanding rubber stress strain is essential for designing durable and reliable products, from tires to medical devices.").

- Clearly define "stress" and "strain" individually.

- Stress: Explain it as the force applied per unit area. Use simple examples like stretching a rubber band.

- Strain: Define it as the deformation of the material relative to its original size. Again, use the rubber band analogy.

- Then, define "rubber stress strain" as the relationship between these two when applied to a rubber material.

- Briefly mention the factors influencing rubber stress strain (e.g., temperature, loading rate, material composition).

- Outline the scope of the guide: What will the reader learn? What areas will be covered?

2. Fundamentals of Stress

This section will dive deeper into the concept of stress.

2.1 Types of Stress

- Tensile Stress: Stress caused by pulling or stretching forces.

- Example: Stretching a rubber band.

- Compressive Stress: Stress caused by pushing or squeezing forces.

- Example: Compressing a rubber ball.

- Shear Stress: Stress caused by forces acting parallel to a surface.

- Example: Cutting a piece of rubber with scissors.

2.2 Stress Calculation

- Provide the basic formula for calculating stress: Stress = Force / Area

- Explain the units of stress (e.g., Pascals (Pa), pounds per square inch (psi)).

- Illustrate with a simple example: A rubber block with a given cross-sectional area subjected to a specific force. Calculate the stress.

3. Fundamentals of Strain

Similar to the stress section, this part elaborates on strain.

3.1 Types of Strain

- Tensile Strain: Change in length due to tensile stress.

- Compressive Strain: Change in length due to compressive stress.

- Shear Strain: Change in angle due to shear stress.

3.2 Strain Calculation

- Explain the formula for calculating strain: Strain = (Change in Length) / (Original Length)

- Note that strain is dimensionless.

- Provide an example calculation using a rubber sample.

4. The Rubber Stress Strain Curve

This is a crucial section visualizing the relationship.

4.1 Explanation of the Curve

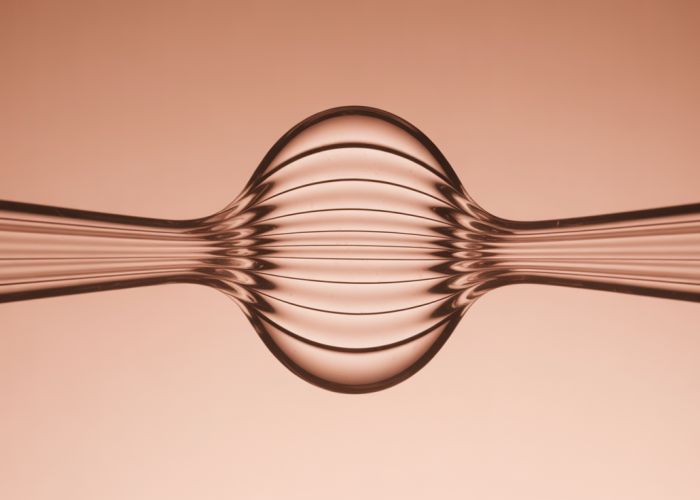

- Introduce the stress-strain curve as a graphical representation of the material’s response to applied force.

- Explain the axes: Stress on the y-axis, Strain on the x-axis.

- Describe the key regions of the curve, using a diagram or illustration:

- Elastic Region: The linear portion where the rubber returns to its original shape after the stress is removed. Relate this to Hooke’s Law.

- Yield Point: The point beyond which the rubber begins to deform permanently.

- Plastic Region: The region where permanent deformation occurs.

- Ultimate Tensile Strength (UTS): The maximum stress the rubber can withstand before it starts to neck down (decrease in cross-sectional area).

- Fracture Point: The point at which the rubber breaks.

4.2 Key Material Properties Derived from the Curve

- Young’s Modulus (Elastic Modulus): Defined as the slope of the stress-strain curve in the elastic region. Relates to stiffness.

- Tensile Strength: The maximum stress a material can withstand before failure.

- Elongation at Break: The strain at the point of fracture.

- Resilience: The ability of the rubber to absorb energy when deformed elastically and release that energy upon unloading. Relate this to the area under the elastic region of the curve.

5. Factors Affecting Rubber Stress Strain

This section explores variables influencing the behavior.

5.1 Temperature

- Explain how temperature affects the elastic modulus and tensile strength.

- Higher temperatures generally lead to lower modulus and tensile strength.

5.2 Strain Rate

- Explain how the speed of applying stress impacts the material response.

- Higher strain rates can increase the stiffness and tensile strength.

5.3 Material Composition

- Discuss how different types of rubber (e.g., natural rubber, synthetic rubber) exhibit different stress-strain behaviors.

-

Also mention the impact of fillers, plasticizers, and other additives. Provide a table example:

Additive Effect on Stress Strain Carbon Black Increases stiffness, tensile strength, and abrasion resistance Plasticizers Decreases stiffness, increases flexibility Sulfur (Vulcanization) Increases crosslinking, improves strength and elasticity

6. Applications of Rubber Stress Strain Analysis

Show the practical relevance of the topic.

6.1 Product Design

- Explain how understanding "rubber stress strain" is crucial for designing durable and reliable rubber products.

- Examples: Tires, seals, hoses, vibration dampers.

6.2 Material Selection

- Discuss how "rubber stress strain" data helps engineers choose the right rubber material for a specific application.

6.3 Failure Analysis

- Explain how "rubber stress strain" analysis can be used to investigate the cause of rubber product failures.

7. Testing Methods for Rubber Stress Strain

Describe how this data is acquired.

7.1 Tensile Testing

- Explain the procedure for performing a tensile test on a rubber sample.

- Describe the equipment used (e.g., universal testing machine).

- Mention relevant standards (e.g., ASTM D412).

7.2 Compression Testing

- Explain the procedure for performing a compression test.

- Describe the equipment and relevant standards.

7.3 Hardness Testing

- While not directly measuring stress-strain, explain how hardness relates to the material’s resistance to deformation.

- Describe common hardness scales (e.g., Shore A).

8. Common Mistakes and Misconceptions

Address potential misunderstandings.

- Mixing up stress and strain.

- Assuming linear behavior beyond the elastic region.

- Ignoring the effects of temperature and strain rate.

- Using inappropriate testing methods.

Rubber Stress Strain: Frequently Asked Questions

Here are some common questions about rubber stress strain to help you understand the concepts better.

What exactly is rubber stress strain?

Rubber stress strain describes the relationship between the force applied to a rubber material (stress) and the resulting deformation (strain). It’s a key measure of rubber’s elasticity and ability to return to its original shape after being stretched or compressed. Understanding this relationship is crucial in various engineering applications.

Why is understanding rubber stress strain important?

Knowing the rubber stress strain characteristics allows engineers to predict how rubber components will behave under load. This information is crucial for designing reliable and durable products like tires, seals, and vibration isolators. Without it, premature failure can occur.

How does temperature affect rubber stress strain?

Temperature significantly impacts rubber stress strain behavior. Higher temperatures generally decrease the stiffness of the rubber, leading to lower stress values at a given strain. Conversely, lower temperatures can make the rubber more brittle and less flexible, altering the rubber stress strain curve.

What’s the difference between stress and strain in rubber?

Stress is the force applied per unit area of the rubber material. It’s a measure of the internal forces within the rubber resisting deformation. Strain, on the other hand, is the amount of deformation relative to the original size. Think of stress as the cause and strain as the effect when analyzing rubber stress strain.

Alright, that’s the lowdown on rubber stress strain! Hope this guide helped clear things up. Now go forth and put that knowledge to good use! Cheers!