Building security represents a critical area of concern, especially considering contemporary threats. One solution, polyurea blast coating, offers enhanced protection against explosive events. The United States Department of Defense (DOD), a significant advocate for force protection, has explored this technology’s potential. Finite Element Analysis (FEA) assists engineers in simulating blast scenarios to assess the effectiveness of polyurea blast coating. Consequently, the increasing adoption of polyurea blast coating demonstrates its promise as a practical measure against blast-related damage.

Analyzing the Effectiveness of Polyurea Blast Coating for Building Protection

This document outlines a structured approach to crafting an informative article examining the efficacy of polyurea blast coating in safeguarding buildings. The focus will be on providing a clear, analytical perspective on the technology.

1. Introduction: Setting the Stage

- Hook: Begin with a compelling scenario or statistic highlighting the increasing threat of explosions and the need for building protection. For example, referencing a recent blast incident and its structural consequences.

- Defining Polyurea Blast Coating: Clearly and concisely define what polyurea blast coating is. Emphasize its polymeric nature and its application process. Avoid overwhelming the reader with chemical details early on.

- Thesis Statement: State the article’s central argument. This should address the core question of whether polyurea blast coating effectively protects buildings, acknowledging both its potential benefits and limitations.

2. Understanding the Threat: Why Blast Protection Matters

2.1. Types of Explosions and Their Impact

- Brief overview: Categorize the main types of explosions buildings might face (e.g., accidental industrial explosions, terrorist attacks, natural gas leaks).

- Blast Wave Characteristics: Explain the properties of a blast wave (e.g., pressure, duration, impulse) and how these characteristics affect building structures. Use diagrams to illustrate blast wave propagation and interaction with buildings.

- Common Building Failure Modes: Describe how explosions typically damage buildings. This can include:

- Window breakage and fragmentation

- Wall collapse (partial or complete)

- Structural frame damage

- Flying debris hazards

2.2. Vulnerable Building Types

- Critical Infrastructure: Highlight structures particularly vulnerable and important to protect, such as:

- Government buildings

- Hospitals

- Schools

- Power plants

- Transportation hubs

- High-Occupancy Buildings: Discuss buildings with large populations that require enhanced safety measures (e.g., office buildings, apartment complexes, stadiums).

3. Polyurea Blast Coating: The Technology Explained

3.1. Material Properties

- Chemical Composition (Simplified): Briefly mention the key chemical components of polyurea, emphasizing its rapid curing time and flexibility.

- Key Performance Characteristics: Explain the properties that make polyurea suitable for blast mitigation:

- High tensile strength

- Excellent elongation

- Impact resistance

- Adhesion to various substrates

- Chemical resistance

- Application Process: Describe the typical application method, including surface preparation, mixing, and spraying techniques. Use visual aids like illustrations or diagrams.

3.2. How Polyurea Blast Coating Works

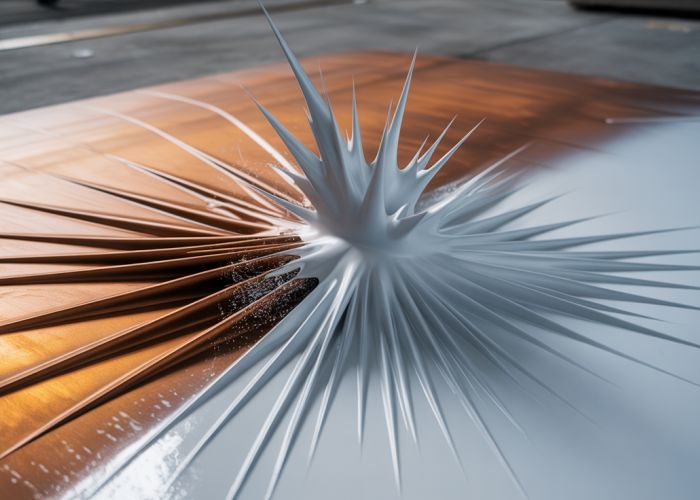

- Energy Absorption: Explain how the polyurea coating absorbs and dissipates the energy of a blast wave.

- Deformation and Load Distribution: Illustrate how the coating allows the structure to deform under pressure while preventing catastrophic failure.

- Fragment Retention: Emphasize the coating’s ability to contain flying debris, reducing the risk of injury.

4. Evidence of Effectiveness: Testing and Real-World Applications

4.1. Experimental Testing

- Blast Simulation Tests: Describe the different types of blast simulation tests used to evaluate polyurea coating performance.

- Key Metrics: Explain the metrics used to assess effectiveness, such as:

- Reduced structural deflection

- Lower peak pressures

- Limited fragmentation

-

Summarize Test Results: Present key findings from relevant studies. Use a table to compare the performance of coated versus uncoated structures.

Metric Uncoated Structure Coated Structure Percentage Reduction Peak Deflection (mm) 150 50 67% Maximum Pressure (kPa) 300 200 33% Fragment Count 100+ <10 90%+

4.2. Case Studies

- Real-World Examples: Provide examples of buildings where polyurea blast coating has been successfully applied. Highlight the specific challenges faced and the benefits achieved.

- Anecdotal Evidence: Include testimonials or quotes from building owners, engineers, or security experts.

5. Limitations and Considerations

5.1. Cost

- Initial Investment: Discuss the upfront cost of applying polyurea blast coating.

- Long-Term Benefits: Contrast the initial cost with the potential savings from reduced damage and repair costs in the event of an explosion.

5.2. Application Challenges

- Surface Preparation: Emphasize the importance of proper surface preparation for optimal adhesion and performance.

- Environmental Factors: Discuss how environmental factors (temperature, humidity) can affect the application process.

- Quality Control: Highlight the need for skilled applicators and rigorous quality control measures.

5.3. Alternative Solutions

- Comparison with other blast mitigation techniques: Briefly mention other strategies such as laminated windows, reinforced walls, and standoff distances. Compare and contrast these alternatives with polyurea blast coating in terms of cost, effectiveness, and practicality.

Polyurea Blast Coating FAQs

This section answers frequently asked questions about polyurea blast coatings and their effectiveness in protecting buildings.

How does polyurea blast coating protect buildings from explosions?

Polyurea blast coating is a tough, flexible material sprayed onto building surfaces. When an explosion occurs, the coating absorbs and dissipates energy, preventing fragments from flying inward and minimizing structural damage. It essentially acts as a shock absorber.

Is polyurea blast coating suitable for all types of buildings?

Polyurea blast coating can be applied to a variety of structures, including commercial buildings, government facilities, and industrial sites. Its suitability depends on factors like the building’s construction, location, and potential threat level. Consulting with a professional is crucial.

How durable is polyurea blast coating? Does it require frequent maintenance?

Polyurea blast coating is extremely durable and resistant to abrasion, chemicals, and weathering. While specific lifespan depends on environmental conditions, it generally requires minimal maintenance compared to other protective measures. Regular inspections are recommended.

What is the application process for polyurea blast coating?

The application process involves surface preparation followed by spraying the polyurea blast coating onto the structure. Proper surface cleaning and preparation are critical for optimal adhesion and performance. Trained and certified applicators should handle the process.

So, what do you think? Is polyurea blast coating the right choice for your project? Hopefully, this article has given you some food for thought. Let me know your questions in the comments!