Understanding linear measurement is crucial in various fields, and the debate of mm versus inch continues to be a relevant topic for professionals and hobbyists alike. Engineering specifications often require precise measurements, and the choice between millimeters (mm) and inches often affects project outcomes. Consider the implications of this choice when using CAD software, which relies on accurate unit selection for design and manufacturing. Further, consider ISO standards, which frequently employ metric units such as millimeters. These considerations underscore the importance of a thorough understanding of mm versus inch.

Measurement is an integral part of our existence, silently shaping our understanding of the world around us. From the dimensions of our homes to the specifications of the devices we use, measurement provides a common language for describing and quantifying physical attributes.

Two systems, however, dominate the landscape: the metric system, with the millimeter (mm) as a fundamental unit, and the imperial system, primarily using the inch (in). Understanding their differences, applications, and conversion is crucial in various fields.

This guide aims to provide a comprehensive and definitive understanding of the mm versus inch debate. We’ll delve into their individual characteristics, compare their strengths and weaknesses, and equip you with the knowledge to navigate between them effectively.

The Ubiquitous Nature of Measurement

Measurement is more than just assigning numbers to physical quantities. It’s the foundation upon which we build, design, and innovate.

Think about it: recipes require precise measurements of ingredients, construction projects rely on accurate dimensions, and scientific experiments demand meticulous data collection.

In essence, measurement is the backbone of both everyday life and highly specialized fields.

Metric vs. Imperial: A Tale of Two Systems

The world of measurement is largely divided between two primary systems: the metric system and the imperial system.

The metric system, with its base-10 structure, offers simplicity and ease of conversion. The millimeter is a key unit within this system, commonly used for precision measurements in engineering, manufacturing, and other technical fields.

Conversely, the imperial system, still prevalent in the United States, relies on units like the inch, foot, and yard.

While conversions within the imperial system can be less intuitive, its familiarity in certain industries and regions necessitates a solid understanding.

Purpose and Scope of This Guide

This guide is designed to bridge the gap between the metric and imperial systems, focusing specifically on the relationship between millimeters and inches.

Our goal is to provide clarity and practical knowledge, covering the following key areas:

- Defining millimeters and inches within their respective systems.

- Comparing the advantages and disadvantages of each system.

- Providing practical conversion techniques and tools.

- Exploring real-world applications across various industries.

- Offering guidance on when to use millimeters versus inches.

By the end of this guide, you’ll have a firm grasp of the mm versus inch dynamic, empowering you to make informed decisions and work effectively with both units of measurement.

Conversely, the imperial system, still prevalent in the United States, relies on a more complex, less intuitive structure. Before comparing these systems directly, it’s crucial to understand each on its own terms. Let’s begin by dissecting the millimeter, a cornerstone of the metric system, and explore its definition, properties, and practical applications.

Decoding the Basics: Millimeters (mm) Explained

The millimeter (mm) is a fundamental unit of length within the metric system, a system celebrated for its simplicity and decimal-based nature. Understanding its definition and relationship to other metric units is crucial for grasping its significance.

Defining the Millimeter

A millimeter is defined as one-thousandth of a meter (1/1000 m).

In simpler terms, if you divide a meter into 1000 equal parts, each part would be a millimeter.

This decimal-based relationship is a hallmark of the metric system, making conversions straightforward and intuitive.

The Millimeter’s Place in the Metric System

The millimeter is closely related to other units within the metric system:

- Centimeter (cm): 1 centimeter equals 10 millimeters (1 cm = 10 mm).

- Meter (m): 1 meter equals 1000 millimeters (1 m = 1000 mm).

- Kilometer (km): 1 kilometer equals 1,000,000 millimeters (1 km = 1,000,000 mm).

This consistent decimal progression makes conversions between units as easy as multiplying or dividing by powers of 10.

This contrasts sharply with the more complex and less intuitive relationships found in the imperial system.

Common Uses of Millimeters

Millimeters are widely used in situations where precision is required. Here are some examples:

-

Engineering: Technical drawings and specifications often use millimeters to define the dimensions of components.

-

Manufacturing: Machining and fabrication processes rely on millimeters for accurate measurements.

-

Photography: The focal length of camera lenses is often expressed in millimeters.

-

3D Printing: Accuracy is essential in 3D printing. Designs are developed in millimeters and printed accordingly.

-

Paper Sizes: Standard paper sizes, like A4, are defined in millimeters (210 mm x 297 mm).

-

Measuring Small Objects: The thickness of a coin, the diameter of a wire, or the size of a screw are all commonly measured in millimeters.

The millimeter’s versatility and precision make it an indispensable unit of measurement across a wide range of fields. Its integration within the decimal-based metric system further enhances its ease of use and applicability.

Decoding the Basics: Inches (in) Explained

Having established the millimeter as a cornerstone of the metric system, we now turn our attention to its counterpart in the imperial system: the inch. Though less intuitive in its structure than the millimeter, the inch holds significant historical and practical relevance, particularly in the United States. Understanding its definition, fractional representation, and relationship to other imperial units is essential for anyone navigating a world where both systems coexist.

Defining the Inch

The inch (in) is a unit of length within the Imperial System, also known as the United States Customary System.

Unlike the millimeter, which is defined decimally, the inch has a more complex historical foundation.

An inch is often defined in relation to other imperial units.

Specifically, it is equal to 1/12 of a foot.

While its exact origin is debated, it is believed to have been derived from human body measurements.

Fractional Representation

One of the defining characteristics of the inch is its fractional representation.

Inches are commonly divided into fractions such as 1/2, 1/4, 1/8, and 1/16 of an inch.

This fractional approach, while seemingly less straightforward than the metric system’s decimal base, remains deeply ingrained in many industries and everyday practices.

Understanding these fractions is crucial for accurate measurement and communication when working with inches.

For even greater precision, smaller fractions like 1/32 or even 1/64 of an inch are sometimes used, particularly in specialized fields like machining.

The Inch’s Place in the Imperial System

The inch is closely linked to other units within the imperial system:

- Foot (ft): 1 foot equals 12 inches (1 ft = 12 in).

- Yard (yd): 1 yard equals 36 inches (1 yd = 36 in).

- Mile (mi): 1 mile equals 63,360 inches (1 mi = 63,360 in).

These relationships, while not decimal-based, are essential for converting between different imperial units.

Mastering these conversions is critical for tasks such as calculating distances, determining material sizes, and understanding construction plans.

Common Uses of Inches

Despite the increasing adoption of the metric system globally, inches remain prevalent in several contexts, particularly in the United States.

- Construction: Inches are frequently used in building plans, lumber dimensions, and pipe sizes.

- Manufacturing: Many American manufacturers continue to use inches for specifying product dimensions and tolerances.

- Everyday Measurements: Inches are commonly used for measuring the size of screens (TVs, monitors), paper, and clothing.

- Hardware: Bolt lengths, screw sizes, and drill bit diameters are often specified in inches.

The continued use of inches in these areas highlights the importance of understanding this unit of measurement, even in a world increasingly dominated by the metric system.

Having explored the individual characteristics of both millimeters and inches, it’s time to place these units side-by-side. Understanding each system’s strengths and weaknesses is crucial for effective communication and practical application in a world where both systems continue to play significant roles.

Metric vs. Imperial: A Head-to-Head Comparison

The co-existence of the metric and imperial systems often leads to confusion, but understanding their differences, advantages, and disadvantages can clarify their respective roles. This section provides a detailed comparison, considering ease of use, global adoption, historical context, and the necessity of conversion.

Ease of Use: Decimal vs. Fractional

The metric system’s decimal-based structure offers a clear advantage in terms of ease of use. Conversions within the metric system involve multiplying or dividing by powers of 10, making calculations straightforward and intuitive.

For example, converting millimeters to meters simply requires dividing by 1000.

The imperial system, with its fractional representation of inches and inconsistent relationships between units (12 inches in a foot, 3 feet in a yard, etc.), can be more challenging to learn and use.

This complexity often leads to errors, especially in tasks requiring precise measurements.

Global Adoption: A Tale of Two Systems

The metric system enjoys widespread global adoption, serving as the primary system of measurement in most countries worldwide. This near-universal acceptance facilitates international trade, scientific collaboration, and engineering projects.

The United States remains a notable exception, continuing to use the imperial system for many everyday applications.

This creates a situation where individuals and industries must be proficient in both systems to effectively interact on a global scale.

Advantages and Disadvantages Summarized

| Feature | Metric System (mm) | Imperial System (in) |

|---|---|---|

| Ease of Use | Decimal-based, simple conversions | Fractional, complex conversions |

| Global Adoption | Widely adopted, international standard | Primarily used in the United States |

| Scientific Use | Preferred for scientific applications | Less common in scientific contexts |

| Engineering Use | Gaining traction due to standardization | Still used in some industries, like aerospace |

| Everyday Use (US) | Limited | Prevalent in construction and DIY projects |

The Importance of Conversion

Given the parallel existence of these two systems, the ability to convert between them is essential.

Whether it’s interpreting product specifications, collaborating with international partners, or working on projects that require adherence to specific standards, understanding how to accurately convert between millimeters and inches is crucial.

Historical Context: Why Both Systems Persist

The historical context sheds light on why both systems continue to exist.

The imperial system evolved organically over centuries, with units often based on human body measurements.

While seemingly arbitrary, these units became deeply ingrained in certain cultures and industries.

The metric system, developed in the late 18th century, aimed to create a rational and standardized system of measurement.

Despite its inherent advantages, the transition to the metric system has been gradual and incomplete in some parts of the world due to established practices and economic considerations.

Having explored the individual characteristics of both millimeters and inches, it’s time to place these units side-by-side. Understanding each system’s strengths and weaknesses is crucial for effective communication and practical application in a world where both systems continue to play significant roles.

Real-World Relevance: Applications Across Industries

The choice between millimeters and inches isn’t merely academic; it’s a pragmatic decision deeply embedded in the workflows of various industries. From the precision manufacturing of microchips to the large-scale construction of skyscrapers, the selected unit of measurement directly impacts accuracy, efficiency, and ultimately, the success of a project. Let’s examine how these units are employed across diverse sectors.

Manufacturing: Navigating a Dual System

Manufacturing often operates on a global scale, forcing companies to grapple with both metric and imperial systems. A component designed in millimeters in Germany might need to interface with a part manufactured in inches in the United States.

This necessitates a robust system of conversion and quality control.

International clients often dictate the required unit of measurement based on their regional standards.

Imagine a company producing precision gears: Some clients may require dimensions in millimeters for seamless integration with existing metric-based machinery, while others might demand inch-based specifications.

The ability to seamlessly switch between systems is therefore a competitive advantage.

Engineering: Precision in Design and Specifications

Engineering design and specifications demand unparalleled accuracy. Whether it’s designing a bridge, a microchip, or an aircraft engine, the chosen units of length are foundational.

The metric system’s decimal-based structure often lends itself to complex calculations, which is why it is more common in the field.

Millimeters are often favored in precision engineering due to their smaller scale, allowing for finer tolerances.

However, in some countries (like the USA), certain engineering disciplines may still rely on inches, particularly in legacy systems or established industries. This creates a constant need for engineers to be fluent in both systems and capable of converting between them without error.

Construction: Building the World, Unit by Unit

Construction projects are tangible manifestations of design, and the units of measurement used dictate the physical reality of the structure.

Regional standards and building codes often determine the dominant system.

In countries predominantly using the metric system, construction blueprints will specify dimensions in millimeters or meters. Conversely, in the United States, inches and feet are the norm.

This distinction extends to the tools and materials used: Lumber, piping, and other building components are often manufactured to standard sizes based on the prevailing measurement system.

This can lead to complications when working on international projects or importing materials from countries using a different system.

The Tools of the Trade: Rulers, Tape Measures, and Potential Pitfalls

The humble ruler and tape measure are ubiquitous tools, but their effective use requires a keen understanding of both millimeters and inches.

Reading errors are common, especially when dealing with fractional inches or attempting to convert mentally between systems.

It’s crucial to select the appropriate tool for the job and to double-check measurements to avoid costly mistakes.

Digital calipers and laser measuring tools are becoming increasingly prevalent, offering higher precision and reducing the likelihood of human error.

However, even with these advanced tools, a solid grasp of fundamental measurement principles remains essential.

Having explored the individual characteristics of both millimeters and inches, it’s time to place these units side-by-side. Understanding each system’s strengths and weaknesses is crucial for effective communication and practical application in a world where both systems continue to play significant roles. The choice between millimeters and inches isn’t merely academic; it’s a pragmatic decision deeply embedded in the workflows of various industries. From the precision manufacturing of microchips to the large-scale construction of skyscrapers, the selected unit of measurement directly impacts accuracy, efficiency, and ultimately, the success of a project. Let’s examine how these units are employed across diverse sectors. Navigating this landscape effectively requires not just an understanding of each unit, but also the ability to seamlessly translate between them. This is where mastering the art of conversion becomes paramount.

Mastering the Conversion: Techniques and Tools

The ability to convert between millimeters (mm) and inches (in) is an indispensable skill in today’s interconnected world. Whether you’re a seasoned engineer, a DIY enthusiast, or simply trying to decipher a foreign product manual, understanding how to accurately translate between these units is essential. This section provides a practical guide to conversion techniques and tools, empowering you to navigate the metric and imperial systems with confidence.

Essential Conversion Factors

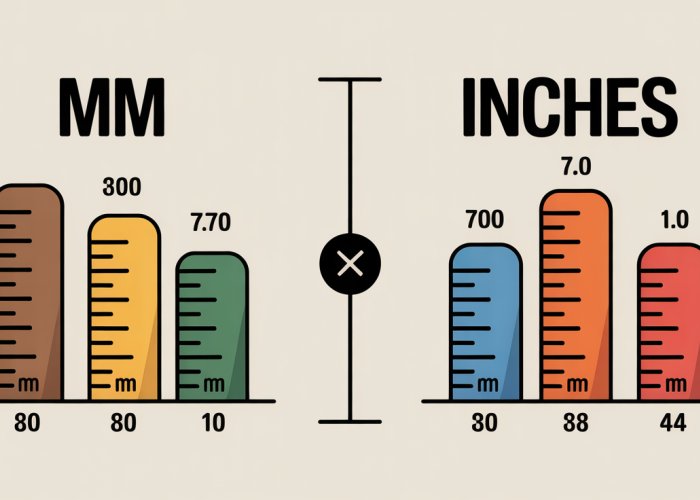

At the heart of any conversion lies a fundamental understanding of the relationship between the units. Here are the most crucial conversion factors to memorize:

- 1 inch (in) = 25.4 millimeters (mm) (This is the defining relationship)

- 1 millimeter (mm) = 0.0393701 inches (in) (For converting from metric to imperial)

These constants form the bedrock of all mm-to-inch and inch-to-mm calculations. Keep these two conversion factors at your fingertips, because they are key to mastering the conversion process.

Manual Conversion Formulas: Step-by-Step

While online tools offer convenience, knowing how to perform manual conversions provides a deeper understanding of the process.

Millimeters to Inches:

To convert millimeters to inches, divide the millimeter value by 25.4.

Formula: inches = millimeters / 25.4

Example: Convert 50 mm to inches.

inches = 50 mm / 25.4 = 1.9685 inches (approximately).

Inches to Millimeters:

To convert inches to millimeters, multiply the inch value by 25.4.

Formula: millimeters = inches

**25.4

Example: Convert 2 inches to millimeters.

millimeters = 2 inches** 25.4 = 50.8 mm.

Performing these calculations provides a transparent view of the conversion process. It empowers you to understand exactly how one unit of measurement relates to the other.

Navigating Online Conversion Tools: A Critical Eye

The internet offers a plethora of conversion tools, ranging from simple calculators to sophisticated software. While these tools can be incredibly useful, it’s crucial to approach them with a critical eye.

Reliable Resources:

Opt for reputable sources such as:

- Dedicated unit conversion websites (e.g., Google Unit Converter)

- Engineering resources and calculators.

- Scientific calculators.

These platforms typically employ accurate algorithms and regularly updated conversion factors.

Beware of Inaccurate Sources:

Be wary of:

- Obscure or unverified websites.

- Calculators with limited decimal places.

- Sources that haven’t been recently updated.

Always double-check the results, particularly when dealing with high-precision applications.

Maintaining Precision and Accuracy: Avoiding Critical Errors

In the world of measurement, precision and accuracy are paramount. Failing to maintain these principles during conversions can lead to significant errors, particularly in engineering, manufacturing, and construction.

Potential Pitfalls:

- Rounding Errors: Prematurely rounding numbers can accumulate errors, especially in multi-step calculations.

- Incorrect Conversion Factors: Using outdated or incorrect conversion factors will yield inaccurate results.

- Unit Confusion: Ensure you’re converting between the correct units (e.g., millimeters to inches, not millimeters to feet).

Best Practices:

- Carry calculations to several decimal places and only round the final answer.

- Always use the precise conversion factor (25.4) for millimeters and inches.

- Clearly label all units to avoid confusion.

- Validate your results by comparing them with known benchmarks or using multiple conversion methods.

By meticulously following these guidelines, you can minimize the risk of errors and ensure the integrity of your measurements. Mastering the conversion between millimeters and inches isn’t just about performing calculations; it’s about cultivating a mindset of precision and accuracy.

Having mastered the conversion techniques and equipped ourselves with the necessary tools, it’s time to delve into the core principles that underpin all measurements: precision and accuracy. Understanding these concepts is not merely academic; it’s fundamental to ensuring the reliability and validity of any measurement, conversion, or calculation.

Precision and Accuracy: The Cornerstone of Measurement

In the realm of measurement, precision and accuracy are often used interchangeably, but they represent distinct and crucial qualities. Misunderstanding these terms can lead to significant errors, impacting everything from manufacturing tolerances to scientific research.

Defining Precision and Accuracy

Accuracy refers to how close a measurement is to the true or accepted value. A measurement is considered accurate if it is near the actual value of what is being measured.

Precision, on the other hand, refers to the repeatability or reproducibility of a measurement. A precise measurement is one that can be consistently reproduced, even if it’s not necessarily close to the true value.

To illustrate the difference, consider a target shooting analogy.

- High accuracy and high precision: All shots are clustered tightly around the bullseye.

- High precision but low accuracy: All shots are clustered tightly together, but far from the bullseye.

- High accuracy but low precision: Shots are scattered around the bullseye, but their average position is close to the center.

- Low accuracy and low precision: Shots are scattered randomly across the target.

The Impact of Conversion Errors

Errors introduced during the conversion between millimeters and inches can have significant repercussions across various fields.

In manufacturing, for example, incorrect conversions can lead to parts that don’t fit together properly, resulting in defective products and costly rework. Imagine a scenario where a component designed in millimeters is incorrectly converted to inches during production. The resulting discrepancy, even if seemingly small, can cause assembly issues or compromise the structural integrity of the final product.

Similarly, in engineering, inaccurate conversions can lead to flawed calculations and designs, potentially jeopardizing the safety and performance of structures or systems. A bridge designed with incorrectly converted measurements, for instance, could experience structural failure under stress.

These examples highlight the critical need for meticulous attention to detail during the conversion process and a thorough understanding of the potential consequences of errors.

Calibrated Instruments and Reliable Methods

Ensuring the integrity of measurements requires the use of calibrated instruments and reliable conversion methods.

Calibrated instruments are those that have been tested and adjusted to ensure that they provide accurate readings. Regular calibration is essential to account for wear and tear, environmental changes, and other factors that can affect instrument performance.

Reliable conversion methods include using established conversion factors, double-checking calculations, and employing trusted online conversion tools. It is crucial to be wary of unverified sources or shortcuts that may compromise accuracy.

By prioritizing the use of calibrated instruments and adhering to reliable conversion practices, professionals and enthusiasts alike can minimize the risk of errors and ensure the validity of their measurements. Ultimately, the pursuit of precision and accuracy is not just a matter of technical competence; it’s a commitment to quality, safety, and the integrity of our work.

Having mastered the conversion techniques and equipped ourselves with the necessary tools, it’s time to delve into the core principles that underpin all measurements: precision and accuracy. Understanding these concepts is not merely academic; it’s fundamental to ensuring the reliability and validity of any measurement, conversion, or calculation. This understanding naturally leads us to the practical application of these units: discerning when to use millimeters versus inches in different real-world scenarios.

Use Cases: When to Use MM vs. Inch

The choice between millimeters (mm) and inches (in) isn’t arbitrary. It’s often dictated by industry standards, client preferences, project requirements, and even geographical location. Making the right choice can significantly impact efficiency, clarity, and ultimately, the success of a project.

Industry Standards and Conventions

Different industries have, over time, gravitated towards one system or the other. Understanding these conventions is crucial for effective communication and collaboration.

For example, the automotive industry widely uses the metric system for engine components and specifications, regardless of the country of manufacture. This promotes standardization and reduces the risk of errors in design and assembly.

Conversely, in the United States construction industry, inches and feet remain the standard for building dimensions, lumber sizes, and spatial planning. This deeply ingrained practice necessitates proficiency in the imperial system for anyone working in this sector.

Client Specifications and Preferences

In many situations, the client’s specifications directly influence the choice of measurement unit.

International projects, for instance, may require adherence to metric standards to align with global regulations or the preferences of international partners.

Similarly, a US-based client might expect all measurements and designs to be presented in inches, even if the project involves collaboration with engineers from metric-dominant countries. Adapting to the client’s needs is paramount, even if it requires converting between systems.

Project Requirements and Precision

The level of precision required for a specific task can also influence the selection of units. Millimeters, being smaller units, offer a higher degree of precision than inches.

For instance, in microelectronics manufacturing, where tolerances are extremely tight, millimeters are often preferred for their fine-grained resolution.

On the other hand, for large-scale projects like highway construction, inches or feet might suffice, as the level of precision required is less demanding. In these cases, using a smaller unit may not be necessary or even practical.

Illustrative Case Studies

To further clarify these principles, let’s examine a few specific scenarios:

Case Study 1: Scientific Research

In scientific research, the metric system, including millimeters, is almost universally preferred. Its decimal-based nature simplifies calculations and data analysis, and its global adoption facilitates international collaboration.

Imagine a researcher measuring the diameter of a microscopic organism. Millimeters, or even micrometers (one-thousandth of a millimeter), provide the necessary precision for accurate data collection and analysis.

Case Study 2: Furniture Design

A furniture designer creating a piece for a US-based client may choose to work primarily in inches to align with local manufacturing standards and customer expectations. However, if the design involves intricate joinery or hardware sourced from metric-dominant countries, the designer must be equally comfortable working with millimeters.

Case Study 3: International Engineering Project

An international engineering firm designing a bridge may encounter the need to reconcile metric and imperial systems. The design might be initially conceived in meters (metric), but certain components sourced from the US might be specified in inches. This necessitates seamless conversion and careful attention to tolerances to avoid costly errors during construction.

Case Study 4: 3D printing and design

In the realm of 3D printing, the selection of units is crucial for design and manufacturing. While the software can handle both, it’s vital to set the units according to the printer’s specifications, usually millimeters, to avoid scaling errors.

Choosing the Right Unit

Ultimately, the decision of when to use millimeters versus inches requires careful consideration of the specific context.

Factors to consider include:

- Industry standards: Adhere to established conventions within your field.

- Client preferences: Accommodate client expectations whenever possible.

- Project requirements: Choose the unit that provides the necessary level of precision.

- Global context: Consider the need for international collaboration and standardization.

By carefully weighing these factors, professionals can make informed decisions that enhance efficiency, minimize errors, and ensure the successful completion of their projects.

vs. Inch Conversion: FAQs

Got questions about millimeters and inches? Here are some common questions to help clarify the differences and conversions between these units of measurement.

What exactly is a millimeter (mm)?

A millimeter is a unit of length in the metric system. It’s equal to one-thousandth of a meter. Understanding mm helps when comparing mm versus inch in various applications.

Why are both millimeters and inches used?

Different industries and countries favor different measurement systems. The metric system (millimeters) is common globally, while inches are still prevalent in the United States, for example. Being proficient in both helps when dealing with measurements and conversions.

How do I quickly convert between mm and inches?

The key is to remember that 1 inch equals 25.4 millimeters. To convert inches to mm, multiply the number of inches by 25.4. To convert mm to inches, divide the number of mm by 25.4. Having a calculator or conversion tool handy can speed up the mm versus inch conversions.

Is one measurement system better than the other?

Neither system is inherently superior. The "best" system depends on the context and industry standards. Metric measurements (like mm) are often favored for their simplicity and decimal-based nature, whereas inches remain useful in applications where familiarity and legacy equipment are important. Deciding between mm versus inch is largely a matter of preference and practicality.

So, that’s the lowdown on mm versus inch! Hopefully, this guide has cleared things up a bit. Now, go forth and measure confidently!