Understanding metal roof components is crucial for any homeowner considering a durable and long-lasting roofing solution. The Metal Roofing Alliance (MRA), a leading industry advocacy group, provides valuable resources for navigating the complexities of these systems. Specifically, gauges and coatings represent critical considerations when selecting metal roof components. Manufacturers such as McElroy Metal offer various profiles and finishes. Furthermore, proper installation, often requiring specialized tools and techniques, ensures the longevity and performance of your metal roof components.

Metal roofing has emerged as a compelling alternative to traditional roofing materials, captivating homeowners and builders alike. Its ascent in popularity stems from a potent blend of durability, longevity, and aesthetic versatility, making it a worthwhile investment.

Metal roofs stand as a testament to resilience, offering decades of reliable protection against the elements. This enduring quality translates to long-term cost savings, minimizing the need for frequent replacements or repairs.

Beyond its practical advantages, metal roofing offers a captivating array of design options, complementing a wide spectrum of architectural styles. From the sleek lines of standing seam panels to the rustic charm of corrugated metal, metal roofing empowers homeowners to express their unique vision.

Why Understanding Metal Roof Components Matters

A metal roof is more than just a collection of panels; it’s a carefully engineered system comprising various interconnected components. Each element plays a vital role in ensuring the roof’s overall performance and longevity.

For homeowners, grasping the intricacies of these components empowers them to make informed decisions. This knowledge enables them to select the right materials, assess the quality of workmanship, and negotiate effectively with contractors.

Builders, on the other hand, must possess a thorough understanding of metal roof systems to ensure proper installation and compliance with building codes. A well-executed metal roof installation not only enhances the property’s value but also safeguards its structural integrity.

Your Comprehensive Guide to Metal Roof Components

This article serves as your comprehensive, beginner-friendly guide to the essential components of a metal roof system. We aim to demystify the technical jargon and provide clear, concise explanations that empower you to navigate the world of metal roofing with confidence.

Whether you’re a homeowner considering a metal roof for your residence or a builder seeking to expand your expertise, this guide will equip you with the knowledge you need to succeed.

Join us as we delve into the intricacies of metal roofing, exploring each component’s function, materials, and installation techniques.

Metal Roofing Panels: The Foundation of Your Roof

Having established a foundational understanding of metal roofing and its multifaceted advantages, we now turn our attention to the cornerstone of any metal roof system: the panels themselves. These panels serve as the primary defense against the relentless forces of nature, bearing the brunt of rain, snow, wind, and sun. Their selection dictates not only the roof’s aesthetic appeal but also its long-term performance and resilience.

The Defining Role of Metal Roofing Panels

Metal roofing panels are far more than just surface coverings. They are engineered barriers designed to withstand the elements and protect the structure beneath. The material, profile, and installation method all contribute to the panel’s ability to shed water, resist impact, and maintain its integrity over decades.

A Spectrum of Panel Types

The world of metal roofing panels is diverse, offering a range of profiles to suit various architectural styles and performance requirements.

Standing Seam: The Epitome of Weather Resistance

Standing seam panels are characterized by their clean, vertical lines and concealed fastener system.

The interlocking design creates a weathertight seal, preventing water from penetrating the roof even in the most challenging conditions.

This design also allows for thermal expansion and contraction, minimizing the risk of buckling or distortion over time.

Aesthetically, standing seam roofs offer a sleek, modern look that complements contemporary homes and commercial buildings.

Corrugated Metal: A Classic and Versatile Choice

Corrugated metal panels, with their distinctive wavy pattern, evoke a sense of rustic charm and industrial durability.

Their ease of installation makes them a popular choice for DIY projects and agricultural buildings.

Corrugated metal’s inherent strength and affordability have made it a staple in roofing for over a century.

Beyond the Basics: Exploring Other Panel Options

While standing seam and corrugated metal are the most prevalent, other panel types offer unique aesthetics and performance characteristics.

Ribbed panels provide a more pronounced texture than standing seam, while tile-look panels mimic the appearance of traditional clay or concrete tiles.

The choice of panel type ultimately depends on the desired aesthetic, budget, and specific performance requirements of the project.

Material Selection: The Key to Longevity

The material composition of metal roofing panels plays a crucial role in determining their lifespan, corrosion resistance, and overall performance.

Steel: Strength, Durability, and Cost-Effectiveness

Steel is a popular choice for metal roofing due to its exceptional strength, durability, and relatively low cost.

However, steel is susceptible to corrosion, so it’s essential to choose panels with appropriate coatings.

Galvanized steel, coated with a layer of zinc, offers good protection against rust.

Galvalume steel, coated with a combination of zinc and aluminum, provides even greater corrosion resistance.

Aluminum: Lightweight, Corrosion-Resistant, and Reflective

Aluminum is significantly lighter than steel, making it easier to handle and install.

Its inherent resistance to corrosion makes it an ideal choice for coastal environments where salt air can quickly degrade other materials.

Aluminum’s high reflectivity can also help reduce cooling costs in hot climates by reflecting sunlight away from the building.

Other Material Options: Copper and Zinc

While steel and aluminum are the most common, copper and zinc offer unique aesthetic and performance properties.

Copper develops a distinctive green patina over time, adding character and historical charm to a building.

Zinc is also highly corrosion-resistant and can last for over a century with proper installation.

However, copper and zinc are significantly more expensive than steel or aluminum, making them a less common choice for most roofing projects.

Corrugated metal panels, with their distinctive wavy pattern, evoke a sense of rustic charm and offer a cost-effective roofing solution. But the panels alone cannot guarantee complete protection. An often-overlooked yet vital component lies beneath, diligently working to safeguard your investment: the underlayment.

Underlayment: Your Roof’s Secondary Shield

Metal roofs, while incredibly durable, aren’t entirely impervious to the elements. Wind-driven rain, ice dams, or even minor imperfections in panel installation can allow moisture to seep through. This is where the underlayment steps in, acting as a crucial backup barrier against water penetration. Think of it as the unsung hero, silently guarding against potential damage that could compromise the integrity of your entire structure.

The Vital Role of Underlayment

Underlayment serves a critical purpose: to provide a secondary line of defense against water infiltration. Even with perfectly installed metal panels, extreme weather conditions can test the roof’s defenses.

High winds can force rain upwards and under the panels, while ice dams can create a reservoir of water that slowly finds its way through any vulnerable points.

Underlayment is particularly important in areas prone to harsh weather, offering an extra layer of protection against the elements. It also protects the roof deck during installation, before the metal panels are in place.

Choosing the Right Underlayment Material

Selecting the right type of underlayment is crucial for ensuring long-term roof performance. Several materials are available, each with its own strengths and weaknesses. Here’s a closer look at some of the most common options for metal roofs:

Synthetic Underlayment: The Modern Standard

Synthetic underlayments have become increasingly popular due to their superior performance characteristics. Made from materials like polypropylene or polyethylene, these underlayments offer exceptional durability, tear resistance, and water resistance.

They are also typically lighter and easier to handle than traditional felt underlayment, making installation faster and more efficient. Their ability to resist UV degradation during installation is another key advantage.

Self-Adhered Underlayment: Premium Protection

Self-adhered underlayments provide an even higher level of protection, thanks to their ability to create a watertight seal directly to the roof deck. This type of underlayment features an adhesive backing that bonds to the sheathing, preventing water from seeping through even the smallest gaps or imperfections.

Self-adhered membranes are especially useful in critical areas such as valleys, around chimneys, and along eaves, where water is most likely to accumulate. They offer enhanced sealing capabilities and are a great option to consider to maximize protection against water damage.

Felt Underlayment: A Traditional, Economical Option

Felt underlayment, traditionally made from asphalt-saturated paper, has been a roofing staple for many years. While still a viable option, particularly for budget-conscious projects, it has limitations compared to synthetic underlayments.

Felt is less durable, more prone to tearing, and less water-resistant. It also tends to degrade more quickly when exposed to the elements. While cost-effective, its lifespan is generally shorter, potentially leading to higher long-term costs.

Installation Best Practices

Even the best underlayment material will fail if not installed correctly. Proper installation is crucial for maximizing its effectiveness and ensuring long-term roof performance.

-

Overlapping: Ensure proper overlapping of the underlayment sheets, following the manufacturer’s instructions. This creates a shingle-like effect, directing water away from the seams.

-

Sealing Seams: Seal the seams with roofing tape, especially in areas prone to heavy rainfall or snow. This provides an extra layer of protection against water penetration.

-

Fastening Methods: Use the appropriate fasteners to secure the underlayment to the roof deck. Follow the manufacturer’s recommendations for fastener type, spacing, and placement.

By carefully selecting the right underlayment material and following proper installation techniques, you can ensure that your metal roof provides reliable, long-lasting protection against the elements. The underlayment is a vital component to ensure peace of mind.

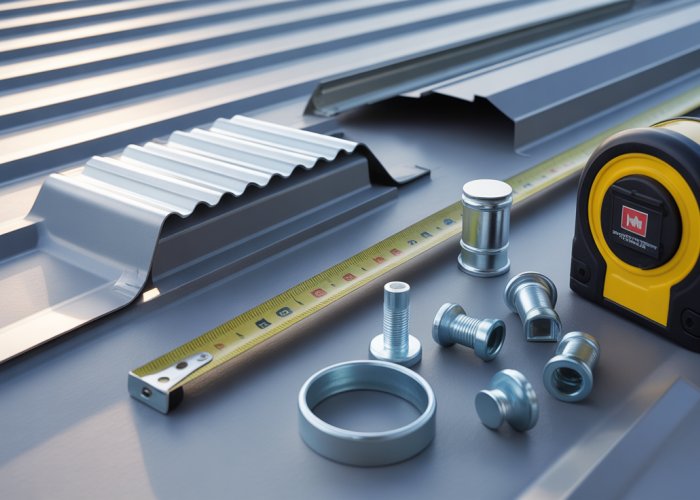

Metal roofing underlayment acts as a crucial moisture barrier beneath the panels, it’s the quality of the connection that truly anchors the roof to the building. This connection relies on fasteners, the unsung heroes that ensure long-term stability and resistance to the relentless forces of nature. Choosing the right fasteners and installing them correctly are paramount to the longevity and performance of your metal roof.

Fasteners: Securing Your Investment

The fasteners used in a metal roofing system are much more than just nails or screws. They are critical components that directly impact the roof’s ability to withstand wind, rain, snow, and even thermal expansion.

Selecting the appropriate fastener is just as important as selecting the right metal panel or underlayment. Compromising on quality or using the wrong type can lead to premature failure, leaks, and costly repairs.

The Critical Role of Fasteners

Fasteners are the linchpin of a metal roof, they bear the responsibility of securely attaching the metal panels, flashing, and other components to the underlying roof structure. They must withstand significant forces, including:

- Wind Uplift: Resisting the force of wind trying to lift the panels off the roof.

- Shear Loads: Holding the panels in place against lateral movement.

- Thermal Stress: Accommodating the expansion and contraction of the metal due to temperature changes.

Without properly selected and installed fasteners, even the most durable metal panels can become vulnerable to damage or even detachment.

Types of Fasteners and Their Applications

The metal roofing industry offers a variety of fasteners, each designed for specific applications and materials. Understanding the differences between them is crucial for ensuring a secure and long-lasting roof.

Screws

Screws are among the most common types of fasteners used in metal roofing. However, not all screws are created equal. Different types are designed for specific purposes:

-

Self-Drilling Screws: These screws are designed to drill their own pilot holes through the metal panel and into the supporting structure, making installation faster and easier. They are ideal for attaching metal panels to metal purlins or steel framing.

-

Wood Screws: As the name suggests, these screws are designed for attaching metal panels to wood sheathing or framing. They typically have a coarser thread pattern for better grip in wood.

-

Considerations for Screws: When using screws, it’s crucial to select the correct length to ensure proper penetration into the supporting structure without protruding excessively. Additionally, using screws with neoprene washers is essential to create a watertight seal around the screw head.

Clips

Clips are primarily used in standing seam roofing systems. These systems are designed to allow for thermal expansion and contraction of the metal panels without putting stress on the fasteners.

-

How Clips Work: Standing seam panels are not directly screwed to the roof deck. Instead, they are attached using clips that are fastened to the deck. The panels then snap or clip onto these fasteners, allowing the metal to expand and contract freely.

-

Benefits of Using Clips: This method prevents the panels from buckling or warping due to temperature changes, which is a common issue with rigidly fastened metal roofs. Clips are particularly important in areas with significant temperature fluctuations.

The Importance of Corrosion Resistance

Metal roofs are designed to last for decades, so it’s essential to use fasteners that can withstand the test of time. Corrosion is a major threat to fasteners, as rust and degradation can weaken them and compromise their holding power.

-

Stainless Steel Fasteners: Stainless steel fasteners offer the best corrosion resistance and are ideal for coastal areas or other environments with high humidity or exposure to salt spray.

-

Coated Fasteners: Alternatively, fasteners coated with protective finishes like zinc or ceramic can also provide good corrosion resistance. These coatings act as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal.

-

Sacrificial Anodes: In some cases, using a fastener made of a metal that is more reactive than the roofing panel can create a sacrificial anode. This means the fastener will corrode first, protecting the more valuable roofing panel.

Proper Spacing and Tightening

Even the best fasteners won’t perform properly if they are not installed correctly. Proper spacing and tightening are crucial for ensuring a secure and watertight roof.

-

Spacing: Fastener spacing should be determined based on the panel manufacturer’s recommendations and local building codes. In general, closer spacing is required in areas with high wind loads.

-

Tightening: Over-tightening fasteners can crush the metal panel or strip the threads, while under-tightening can leave the fastener vulnerable to loosening. It’s important to use a torque-controlled screwdriver or drill to achieve the proper tightening torque.

- Avoid Over-Tightening: Over-tightening can deform the metal around the fastener, creating a pathway for water infiltration.

- Avoid Under-Tightening: Under-tightening can lead to the fastener backing out over time, compromising the roof’s integrity.

By paying close attention to these details, you can ensure that your metal roof fasteners provide the long-lasting performance and protection you expect.

Metal roofing systems, while incredibly durable, are not immune to the threat of water intrusion. While metal panels themselves offer a robust barrier, the areas where the roof is penetrated by chimneys, vents, or where it intersects with walls are particularly vulnerable. This is where flashing comes into play, acting as a crucial shield against leaks and ensuring the longevity of your roofing investment.

Flashing: Guarding Against Leaks in Vulnerable Areas

Flashing is a thin, impervious material used to redirect water away from these vulnerable areas of the roof. It acts as a sealant and a shield, preventing water from seeping into the structure and causing damage. Think of it as the last line of defense where the roof’s primary barrier is interrupted. Without properly installed flashing, even the most robust metal roof can succumb to water damage, leading to costly repairs and structural issues.

Common Flashing Locations: Protecting Critical Areas

Flashing isn’t a one-size-fits-all solution. Its application varies depending on the specific area it’s designed to protect. Understanding these common locations is key to appreciating its importance:

Around Chimneys: Step and Counter Flashing

Chimneys, with their complex shapes and protrusions, present a significant challenge for waterproofing. Two types of flashing are typically employed:

Step flashing consists of individual pieces of flashing that are interwoven with the roofing material along the sides of the chimney.

Each piece directs water away from the chimney and onto the next course of shingles or panels below.

Counter flashing, on the other hand, is embedded into the chimney itself and overlaps the step flashing, providing an additional layer of protection and preventing water from running behind the step flashing.

Around Vents: Ensuring a Watertight Seal

Roof vents, essential for attic ventilation, create another potential entry point for water.

Vent flashing is designed to create a watertight seal around the base of the vent pipe.

It typically consists of a pre-formed collar or flange that integrates with the roofing material, directing water away from the vent opening. The integrity of this seal is crucial to prevent leaks into the attic space.

Valleys: Directing Water Away

Valleys, where two roof slopes meet, are natural channels for water runoff. This concentrated flow requires robust flashing to prevent leaks.

Valley flashing is typically a wider, continuous piece of metal that lines the valley, providing a smooth and watertight channel for water to flow away from the intersection of the roof planes.

Common Flashing Materials: Choosing the Right Defense

The choice of flashing material is crucial for its long-term performance and compatibility with the metal roofing system. Two common options include:

Aluminum: Durable and Corrosion-Resistant

Aluminum is a popular choice for flashing due to its excellent corrosion resistance and workability. It’s lightweight, easy to form, and can withstand the elements without degrading. Its natural resistance to rust makes it an ideal option, especially in areas prone to moisture.

Steel: Strong and Compatible

Steel flashing, particularly galvanized steel, offers strength and compatibility with steel roofing panels. It provides a robust barrier against water intrusion and can be easily integrated into the overall roofing system. The galvanization process protects the steel from rust, ensuring long-term performance.

Proper Flashing Installation: The Key to Success

Even the best flashing materials are useless if not installed correctly. Proper installation techniques are paramount to ensuring a watertight seal and preventing leaks.

This includes:

- Overlapping: Flashing pieces must overlap adequately to ensure that water is directed away from vulnerable areas.

- Sealing: Sealing seams and joints with appropriate sealant is crucial for preventing water from seeping through gaps.

- Fastening: Securely fastening the flashing to the roof structure is essential to prevent it from shifting or becoming dislodged.

Attention to detail and adherence to best practices are essential for ensuring that the flashing effectively protects the roof from water damage.

Flashing is the unsung hero, diverting water with precision, but it’s not the only player in the watertight game. Sealants step in to provide that extra layer of defense, ensuring even the smallest gaps are fortified against the relentless assault of moisture. They are the flexible, tenacious barriers that complement flashing and panel design.

Sealants: Achieving a Watertight Seal

Sealants are indispensable for achieving a truly watertight metal roof. They act as a supplemental barrier, filling in any minute imperfections. They address vulnerable areas where water could potentially infiltrate. Sealants are especially critical at panel seams, fastener penetrations, and transitions between different roofing materials.

The Role of Sealants in Metal Roofing

Sealants play a multifaceted role in safeguarding your metal roof against water damage:

-

Sealing Panel Seams: Metal panels are designed to interlock. Even with precise installation, microscopic gaps can exist. Sealants bridge these gaps, creating a continuous, impermeable barrier.

-

Protecting Fastener Locations: Every screw or clip represents a potential entry point for water. Sealants around fasteners create a watertight seal, preventing corrosion and leaks.

-

Bridging Material Transitions: When a metal roof meets other building components, like walls or chimneys, differential expansion and contraction can create stress points. Sealants accommodate these movements while maintaining a watertight seal.

-

Mitigating Capillary Action: Water can be drawn into tight spaces through capillary action. Sealants prevent this by filling these spaces and disrupting the surface tension that drives water infiltration.

Choosing the Right Sealant: Compatibility is Key

Selecting the appropriate sealant is crucial for long-term performance. Not all sealants are created equal, and compatibility with the metal roofing material is paramount. The ideal sealant should exhibit:

-

Adhesion: Strong adhesion to the metal substrate is essential for a durable, long-lasting seal.

-

Flexibility: Metal roofs expand and contract with temperature changes. The sealant must be flexible enough to accommodate this movement without cracking or losing its seal.

-

Weather Resistance: The sealant must withstand prolonged exposure to UV radiation, temperature extremes, and moisture.

-

Chemical Compatibility: The sealant should be chemically compatible with the metal roofing material to prevent corrosion or degradation.

Two common types of sealants that meet these criteria are polyurethane and silicone-based products.

Polyurethane Sealants: Durable and Flexible

Polyurethane sealants are known for their exceptional durability and flexibility. They form a strong, resilient bond with metal surfaces. They can withstand significant expansion and contraction without compromising the seal. Polyurethane sealants also exhibit excellent resistance to weathering and chemical exposure.

Silicone Sealants: Withstanding Temperature Extremes

Silicone sealants excel in their ability to withstand extreme temperature fluctuations. They maintain their flexibility and sealing properties even in harsh climates. Silicone sealants also offer excellent water resistance. They are a reliable choice for areas exposed to frequent rainfall or snow.

Mastering Sealant Application: Techniques for a Watertight Finish

Proper sealant application is as critical as selecting the right product. Careful surface preparation and precise application techniques are essential for achieving a long-lasting, watertight seal.

-

Surface Preparation: Ensure the surfaces to be sealed are clean, dry, and free of dirt, oil, or debris. Use a suitable cleaner or solvent to remove any contaminants that could compromise adhesion.

-

Proper Bead Size: Apply a bead of sealant that is appropriately sized for the gap being sealed. Too little sealant may not provide adequate coverage, while too much can be messy and wasteful.

-

Consistent Application: Maintain a consistent bead size and application speed for uniform coverage. Avoid air pockets or voids in the sealant bead.

-

Tooling: Tool the sealant immediately after application to create a smooth, professional finish. Tooling forces the sealant into the gap, ensuring optimal adhesion and a watertight seal. Use a clean, rounded tool to avoid tearing or damaging the sealant.

-

Curing Time: Allow the sealant to cure fully according to the manufacturer’s instructions before exposing it to water or other environmental elements.

By understanding the crucial role of sealants and mastering proper application techniques, you can fortify your metal roof against water damage and ensure its longevity. A well-sealed roof is a testament to meticulous attention to detail and a commitment to long-term performance.

Sealants are the steadfast guardians, ensuring even the most vulnerable spots on your metal roof are shielded. However, as we move from the broader sealing strategy to the roof’s highest point, another critical component comes into focus.

Ridge Caps: Guardians of the Roof’s Peak

The ridge cap sits atop your roof, a seemingly simple piece with a vital purpose. It’s more than just an aesthetic finishing touch. It’s the shield that defends the vulnerable peak from water damage. The ridge cap is the final closure, carefully engineered to withstand the elements.

Functionality and Purpose

The primary function of the ridge cap is to seal the apex of the roof. This crucial component prevents water from infiltrating the point where the roof planes meet. Without a properly installed ridge cap, wind-driven rain and snow melt can easily find their way into the attic or underlying structure.

Beyond waterproofing, the ridge cap also provides a clean, finished appearance to the roofline. It creates a visual harmony, complementing the overall aesthetic of the metal roof. The visual impact is substantial, adding a sense of completeness.

Styles and Materials

Ridge caps come in a variety of styles and materials, each with its own set of benefits. Choosing the right type depends on the roof design, climate, and aesthetic preferences.

Matching Metal Ridge Caps

These are crafted from the same metal as the roofing panels, creating a seamless and cohesive look. Their primary advantage is their durability and weather resistance, matching that of the roof itself. The material consistency ensures uniform expansion and contraction, minimizing stress. They offer longevity and a premium aesthetic.

Ventilated Ridge Caps

These specialized ridge caps incorporate vents that promote airflow within the attic space. This ventilation helps to regulate temperature and reduce moisture buildup. Minimizing the risk of condensation, mold growth, and premature deterioration of roofing materials is critical. They are especially beneficial in climates with significant temperature swings.

Installation Best Practices

Proper ridge cap installation is paramount to ensuring a watertight seal and maximizing the lifespan of your metal roof. Several key techniques should be followed.

Overlapping and Sealing

Ridge cap sections should be overlapped properly to prevent water from seeping through the joints. Apply sealant beneath the overlaps to create a watertight barrier. Sealant selection should always align with manufacturer specifications.

Fastening Techniques

Use appropriate fasteners designed for metal roofing. Secure the ridge cap to the roof structure with the correct spacing and tightening. Over-tightening can damage the metal. Under-tightening can lead to leaks and wind uplift. Always use corrosion-resistant fasteners to prevent rust and degradation.

Ensuring a Watertight Seal

The goal is to create a continuous, impermeable barrier along the roof’s peak. Inspect the installed ridge cap carefully for any gaps or imperfections. Address any potential weak points immediately to prevent future water damage. Professional evaluation is highly recommended.

Sealants are the steadfast guardians, ensuring even the most vulnerable spots on your metal roof are shielded. However, as we move from the broader sealing strategy to the roof’s highest point, another critical component comes into focus.

Eaves: Directing Water Away from Your Home

The eaves are more than just an edge to your roof; they are a critical design element that protects your home from water damage. They act as the first line of defense against the elements, channeling water away from the foundation and safeguarding the walls. Neglecting the eaves can lead to serious structural problems.

The Role of Eaves in Water Management

Eaves serve a fundamental purpose: to extend the roofline beyond the exterior walls of the building. This extension is vital for directing rainwater runoff away from the foundation. Without properly functioning eaves, water can accumulate around the base of the building.

This accumulation can lead to a host of problems, including:

- Foundation damage

- Basement flooding

- Soil erosion

- Compromised structural integrity

By effectively channeling water away, eaves help preserve the longevity and stability of the entire structure.

Essential Components of the Eaves

The eaves consist of several key components that work together to ensure effective water management and proper ventilation. Two of the most critical elements are the fascia and the soffit.

Fascia: The Finishing Touch and Protective Barrier

The fascia is the vertical board that caps the ends of the rafters, creating a clean and finished look along the eaves. Beyond aesthetics, the fascia serves as a crucial protective barrier, preventing water from penetrating the rafter ends and causing rot.

It also provides a mounting surface for gutters, which further enhance the eaves’ ability to direct water away from the building. The fascia is often made of wood, aluminum, or composite materials, chosen for their durability and resistance to the elements.

Soffit: Ventilating the Attic and Preventing Moisture Buildup

The soffit is the horizontal surface that spans the underside of the eaves, connecting the fascia to the exterior wall. Its primary function is to ventilate the attic, allowing air to circulate and preventing moisture buildup.

Proper attic ventilation is essential for:

- Preventing mold and mildew growth

- Reducing energy costs

- Extending the lifespan of the roofing materials

Soffits are often vented, featuring small openings or perforations that allow air to flow freely into the attic space. Materials commonly used for soffits include aluminum, vinyl, and wood, each offering varying degrees of durability and aesthetic appeal.

Sealants are the steadfast guardians, ensuring even the most vulnerable spots on your metal roof are shielded. However, as we move from the broader sealing strategy to the roof’s highest point, another critical component comes into focus.

Valleys: Efficient Water Drainage Systems

Valleys are integral to the design of roofs with intersecting planes. These areas, where two roof slopes meet, are natural channels for water runoff.

A well-designed valley is crucial for preventing leaks, protecting the underlying structure, and ensuring the longevity of your metal roof. Neglecting the valleys can lead to significant water damage and costly repairs.

The Importance of Valley Design

Valleys are high-risk areas for water intrusion. The converging slopes concentrate water flow, especially during heavy rainfall or snowmelt.

Proper valley design ensures this water is efficiently channeled off the roof and away from vulnerable areas. This minimizes the risk of leaks and protects the roof deck from moisture damage.

Furthermore, a well-executed valley contributes to the overall structural integrity of the roof by preventing water from pooling and potentially weakening the underlying materials. Efficient water management is paramount for a long-lasting roof.

Materials and Techniques for Durable Valleys

Creating a durable and leak-proof valley requires careful material selection and installation techniques. The best approach will depend on your local climate and the specific design of your roof.

Open Valleys

Open valleys are characterized by exposed metal flashing that directs water flow. They are a simpler design, suitable for regions with moderate rainfall and minimal debris accumulation.

The flashing is typically made of aluminum or steel, chosen for their durability and resistance to corrosion. The flashing must be wide enough to handle the expected water volume.

The simplicity of open valleys makes them relatively easy to install. This can make them a more cost-effective solution. Regular maintenance, such as clearing debris, is essential for their continued effectiveness.

Closed Valleys

Closed valleys offer enhanced protection against water intrusion, making them ideal for areas with heavy rainfall, snow, or significant debris accumulation. In a closed valley, the roofing material itself covers the valley flashing.

This design provides a double layer of protection, minimizing the risk of leaks even under severe weather conditions.

There are two primary types of closed valleys: woven and cut. Woven valleys involve overlapping the roofing material from both sides of the valley. Cut valleys involve overlapping the roofing material from one side of the valley and cutting the material from the other side to create a smooth, water-resistant seam.

Closed valleys require more skill and precision to install than open valleys. However, the added protection they provide can be well worth the investment in challenging climates.

The key to a successful closed valley lies in proper flashing installation, careful alignment of the roofing material, and secure fastening to prevent water from seeping underneath.

So, there you have it – a basic rundown of metal roof components! Hopefully, you’re now a little more confident navigating the world of metal roofing. Good luck with your project, and feel free to ask if anything comes up!