Newton’s Second Law establishes that force is equivalent to the product of mass and acceleration, thus quantifying force. The International System of Units (SI) uses the Newton (N) as the standard unit, with 1 N defined as the force needed to accelerate 1 kilogram at a rate of 1 meter per second squared. Strain gauges, devices that measure the deformation of materials, indirectly determine force by measuring strain caused by applied force. Understanding what measures force requires knowledge of physics and its many instruments. So, engineering applications often utilize load cells, which directly convert force into an electrical signal, to precisely gauge what measures force and it’s effects.

Decoding Force Measurement: A Comprehensive Guide

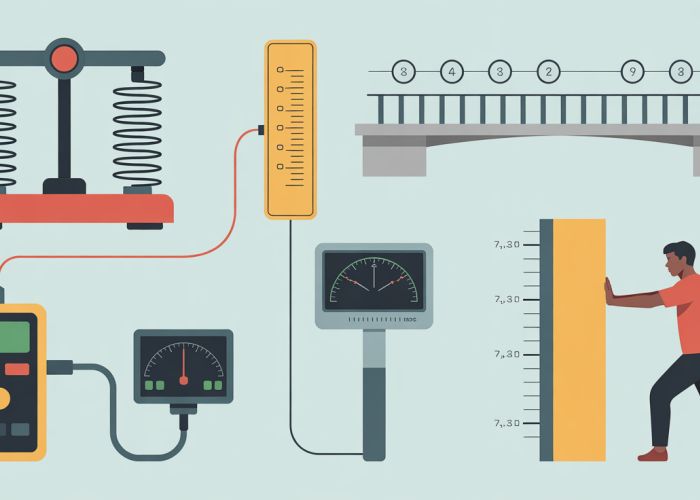

This article delves into the crucial question of "what measures force," providing a detailed explanation of the instruments and methods used to quantify this fundamental physical phenomenon. Understanding force measurement is essential in various fields, from engineering and physics to medicine and sports science.

The Foundation: Defining Force and Its Units

Before exploring the specific instruments, it’s essential to establish a clear understanding of force. Force is a vector quantity that describes an interaction that, when unopposed, will change the motion of an object. In simpler terms, it’s a push or a pull.

- SI Unit: The standard unit of force in the International System of Units (SI) is the Newton (N). One Newton is defined as the force required to accelerate a one-kilogram mass at a rate of one meter per second squared (1 N = 1 kg⋅m/s²).

- Other Units: While the Newton is the preferred unit, other units like pounds-force (lbf) and dynes are still sometimes used in specific contexts.

Primary Instruments for Measuring Force

The following instruments are commonly employed to accurately measure force:

Load Cells

Load cells are transducers that convert force into a measurable electrical signal. They are widely used due to their accuracy, versatility, and ease of integration into various systems.

- Working Principle: Load cells typically utilize strain gauges, which are resistive sensors that change their electrical resistance when subjected to mechanical deformation (strain).

- Types of Load Cells:

- Strain Gauge Load Cells: These are the most common type. Force applied to the load cell causes a small deformation in the strain gauges, which alters their resistance. This resistance change is measured and converted into a force reading.

- Hydraulic Load Cells: These use a fluid-filled chamber where the force applied causes pressure changes. The pressure change is then correlated to the applied force.

- Pneumatic Load Cells: Similar to hydraulic load cells, but they use compressed air instead of fluid.

- Capacitive Load Cells: These load cells use changes in capacitance to measure the applied force.

Force Gauges

Force gauges, also known as push-pull gauges, are handheld instruments specifically designed for measuring tensile and compressive forces.

- Working Principle: Force gauges generally operate on mechanical or electromechanical principles. Mechanical force gauges use a spring mechanism, where the deflection of the spring is proportional to the applied force. Electromechanical force gauges use a load cell integrated within the gauge.

- Applications: Force gauges are frequently used in quality control, materials testing, and ergonomic assessments.

Dynamometers

Dynamometers are sophisticated devices used for measuring torque and rotational speed, and from these measurements, power can be derived. While not directly measuring linear force, they are crucial for assessing the force produced by rotating machinery, engines, and motors.

- Working Principle: Dynamometers typically employ braking mechanisms (e.g., hydraulic, eddy current, or friction brakes) to apply a load to the rotating shaft. The force required to resist this load is measured and used to calculate torque.

- Types of Dynamometers:

- Absorption Dynamometers: These absorb the power produced by the engine or motor being tested.

- Transmission Dynamometers: These measure the power transmitted through a shaft without absorbing it.

- Motor Dynamometers: These can both absorb and supply power, allowing for testing of motors under various load conditions.

Pressure Sensors

While not directly measuring force, pressure sensors are often used to indirectly measure force by relating it to the pressure exerted over a specific area (Force = Pressure x Area).

- Working Principle: Pressure sensors use various technologies (e.g., piezoresistive, capacitive, piezoelectric) to convert pressure into an electrical signal.

- Applications: These are especially useful when dealing with fluid forces or when the force is distributed over a surface.

Factors Influencing Force Measurement Accuracy

Several factors can impact the accuracy of force measurements. It’s crucial to consider these factors to ensure reliable and valid results.

- Calibration: Regular calibration of force measurement instruments is essential. Calibration involves comparing the instrument’s readings to known standards and adjusting the instrument to minimize errors.

- Environmental Conditions: Temperature, humidity, and vibration can affect the performance of force sensors. It’s important to control these variables or compensate for their effects.

- Sensor Overload: Exceeding the rated capacity of a force sensor can damage the sensor and compromise its accuracy.

- Loading Conditions: The way in which the force is applied to the sensor can influence the measurement. Ensure the force is applied axially and without any bending moments.

- Sensor Selection: Choosing the appropriate sensor for the specific application is crucial. Consider the force range, accuracy requirements, and environmental conditions.

Application-Specific Considerations

The choice of force measurement method and instrument often depends on the specific application. Here are a few examples:

| Application | Suitable Instruments | Key Considerations |

|---|---|---|

| Material Testing | Universal Testing Machines (with load cells) | Accuracy, force range, compliance, testing speed |

| Industrial Weighing | Load cells, weighbridges | Capacity, accuracy, environmental protection, legal metrology requirements |

| Medical Research | Force plates, hand dynamometers | Sensitivity, accuracy, range of motion, bio-compatibility |

| Automotive Engineering | Dynamometers, load cells | Torque, power, speed, vibration, environmental conditions |

| Sports Science | Force plates, instrumented treadmills | Ground reaction force, impact forces, running mechanics |

FAQs: Understanding How to Measure Force

Here are some frequently asked questions about measuring force, aiming to clarify key concepts discussed in "What Measures Force? Secrets You Need to Know Now."

What are the common units used to express what measures force?

The most common unit for measuring force is the Newton (N) in the International System of Units (SI). In the Imperial system, pounds (lbs) are frequently used. Understanding these units is crucial when determining what measures force in practical applications.

How do force sensors, like load cells, work to measure force?

Load cells are transducers that convert force into a measurable electrical signal. They typically use strain gauges that deform under pressure, changing their electrical resistance. This change is then calibrated to determine what measures force being applied.

Can what measures force vary depending on the direction of application?

Yes, force is a vector quantity, meaning it has both magnitude and direction. The effect of a force changes based on the angle at which it is applied. Therefore, when considering what measures force, direction is always a critical factor.

Is it possible to directly observe what measures force or do we always rely on instruments?

Directly observing force is usually impossible. We rely on instruments such as spring scales, dynamometers, or force plates to quantify the effects of force and provide a measurable value. These instruments provide the data needed to understand what measures force in a given situation.

Hopefully, you now have a better grip on what measures force! There’s a lot to unpack, but remember the core concepts, and you’ll be well on your way to understanding force in all its forms.