Understanding structural integrity requires a firm grasp of key principles; bending moment inertia is paramount among these. Engineers utilize bending moment inertia in structural design to predict a beam’s resistance to bending under load. Autodesk Revit, a leading BIM software, provides tools for calculating bending moment inertia, crucial for accurate modeling. The American Institute of Steel Construction (AISC) provides standards and guidelines where calculation of bending moment inertia is applied. By understanding the principles, aided by resources and standards from organizations such as AISC, professionals gain valuable tools for understanding and properly designing to resist bending moment inertia.

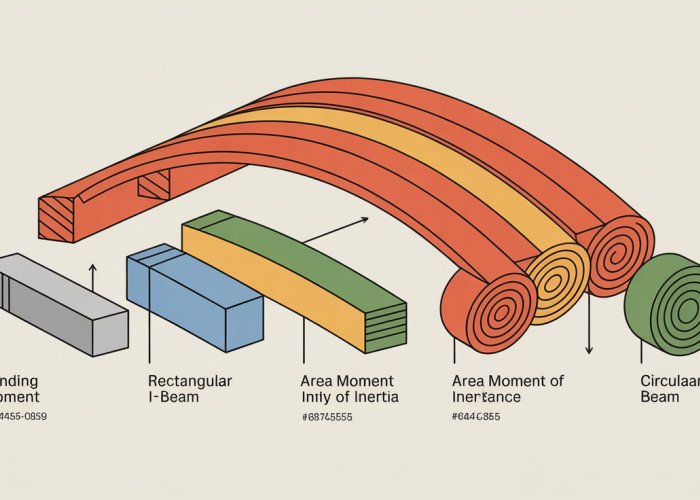

Bending Moment Inertia, also known as Area Moment of Inertia or Second Moment of Area, is a cornerstone concept in engineering. It dictates a structural element’s resistance to bending. Understanding this property is not just an academic exercise; it is a critical skill for engineers across diverse fields. From designing bridges that can withstand tremendous loads to optimizing the lightweight yet robust frames of aircraft, Bending Moment Inertia plays an indispensable role.

The Essence of Bending Moment Inertia

At its core, Bending Moment Inertia quantifies how a structure’s cross-sectional area is distributed relative to its neutral axis. It reflects the efficiency of a shape in resisting bending forces.

A higher Bending Moment Inertia indicates a greater resistance to bending. This means that the material is distributed in a way that maximizes its ability to counteract the stresses induced by bending moments. Think of an I-beam, a common structural element. Its shape places a significant amount of material far from the neutral axis, resulting in a high Bending Moment Inertia and, consequently, excellent bending resistance.

Relevance Across Engineering Disciplines

The principles of Bending Moment Inertia are not confined to a single branch of engineering. Its applications are widespread and crucial in:

- Civil Engineering: Designing bridges, buildings, and other infrastructure to ensure stability and safety under various loads.

- Mechanical Engineering: Optimizing the design of machine components, ensuring they can withstand the forces and stresses of operation without failure.

- Aerospace Engineering: Creating lightweight yet strong aircraft structures that can endure the rigors of flight.

- Automotive Engineering: Designing chassis and frames that provide both safety and performance.

The common thread connecting these diverse applications is the need to create structures that are both strong and efficient. Bending Moment Inertia provides the tools to achieve this balance.

Why a Solid Understanding Is Essential

A comprehensive grasp of Bending Moment Inertia is paramount for any engineer involved in structural design and analysis. A flawed understanding or incorrect application can lead to:

- Structural Failure: Underestimation of stresses can result in catastrophic collapses.

- Inefficient Designs: Over-engineered structures lead to unnecessary material usage and increased costs.

- Compromised Safety: Designs that fail to meet required safety standards pose risks to life and property.

Therefore, a thorough understanding of Bending Moment Inertia is not merely beneficial, but absolutely essential for ensuring the safety, efficiency, and integrity of engineering projects. It empowers engineers to make informed decisions, optimize designs, and ultimately, create structures that stand the test of time.

The principles of Bending Moment Inertia are not confined to a single branch of engineering. Its applications are widespread and crucial in civil, mechanical, and aerospace engineering. Let’s sharpen our focus and provide clarity, offering a precise definition of Bending Moment Inertia, its associated terms, and practical details.

Defining Bending Moment Inertia: A Clear Explanation

Bending Moment Inertia, at times a source of confusion due to its multiple names, is a fundamental property in structural mechanics. It is crucial to precisely understand its definition and related terms to avoid errors in engineering calculations and designs.

Demystifying the Terminology

Bending Moment Inertia, Area Moment of Inertia, and Second Moment of Area are effectively interchangeable terms. They all describe the same geometrical property of a cross-section. This property quantifies how the area of the cross-section is distributed relative to a reference axis.

Think of it as a measure of a shape’s "stiffness" against bending. A higher value indicates a greater resistance to bending forces.

While the terms are synonymous, Bending Moment Inertia is generally favored in the context of beam bending. Area Moment of Inertia emphasizes the geometric nature of the property, and Second Moment of Area highlights its mathematical derivation.

The Formula for Bending Moment Inertia

The Bending Moment Inertia, denoted by the symbol I, is calculated using integral calculus. The general formula depends on the shape of the cross-section and the chosen axis of bending. For a general area A, the formula is:

I = ∫ y2 dA

Here, y is the perpendicular distance from the area element dA to the neutral axis.

The neutral axis is the axis within the beam’s cross-section where there is no bending stress or strain. This integral essentially sums up the contributions of each tiny area element (dA) to the overall resistance to bending, weighted by the square of its distance from the neutral axis.

For common shapes, simplified formulas exist, which will be discussed later. These formulas allow engineers to quickly determine the Bending Moment Inertia without resorting to integration.

Units of Measurement

The units of Bending Moment Inertia are units of length raised to the fourth power. In the International System of Units (SI), this is typically expressed as meters to the fourth power (m4). However, due to the relatively small values encountered in many engineering applications, millimeters to the fourth power (mm4) are frequently used.

In the United States customary units, inches to the fourth power (in4) is the standard unit. It is crucial to maintain consistency in units throughout your calculations to avoid significant errors.

Addressing Potential Confusion

Despite the seemingly straightforward definitions, some confusion can arise. This often stems from:

- Choosing the correct axis: The Bending Moment Inertia is always calculated with respect to a specific axis. The resistance to bending will be different depending on the axis chosen.

- Complex shapes: For complex shapes, breaking them down into simpler components is necessary, often involving the use of the Parallel Axis Theorem, which will be discussed later.

- Units: Always double-check and ensure unit consistency in all calculations.

By keeping these points in mind, engineers can confidently apply the concept of Bending Moment Inertia.

Why Area Moment of Inertia Matters in Beam Design

Having established the definition and terminology surrounding Bending Moment Inertia, it’s time to explore why this property is so vital, especially when designing beams. Understanding its impact on beam deflection and stress distribution is paramount to ensuring structural integrity and preventing catastrophic failures.

The Inverse Relationship Between Area Moment of Inertia and Beam Deflection

The Area Moment of Inertia has a direct and critical impact on beam deflection. Deflection refers to the degree to which a structural element is displaced under a load.

The relationship is inversely proportional: as the Area Moment of Inertia increases, the deflection decreases, and vice versa.

Imagine a simple wooden ruler: easy to bend. Now, envision a steel I-beam: significantly more resistant to bending. This difference in resistance is largely due to the disparity in their Area Moment of Inertia.

Quantifying the Impact

The exact relationship can be seen in beam deflection formulas. A typical deflection equation for a simply supported beam with a concentrated load at the center is:

δ = (PL^3) / (48EI)

Where:

- δ = Deflection

- P = Load

- L = Length of the beam

- E = Young’s Modulus (material property)

- I = Area Moment of Inertia

Notice that I is in the denominator. This confirms that as I increases, δ decreases proportionally. Therefore, doubling the Area Moment of Inertia will halve the deflection, assuming all other factors remain constant.

Area Moment of Inertia and Stress Distribution

Area Moment of Inertia does not only influence deflection; it also significantly impacts the distribution of stress within a beam subjected to bending. Stress, in this context, refers to the internal forces that molecules within a continuous material exert on each other, while strain is the measure of the material’s deformation.

When a beam bends, it experiences compressive stress on one side (the side being pushed together) and tensile stress on the other side (the side being stretched).

The distribution of these stresses is not uniform across the beam’s cross-section.

How I Influences Stress

The Area Moment of Inertia dictates how effectively a beam resists these bending stresses. A larger I means the material is distributed more effectively away from the neutral axis.

This leads to a more even distribution of stress and reduces the peak stress experienced by the beam.

Conversely, a smaller I concentrates stress, potentially leading to localized yielding or failure.

The relationship between bending stress (σ), bending moment (M), the distance from the neutral axis (y), and the Area Moment of Inertia is given by the flexure formula:

σ = (My) / I

Again, I is in the denominator, indicating that for a given bending moment, a larger Area Moment of Inertia results in lower stress.

The Consequences of Inadequate Area Moment of Inertia

Failing to properly account for Area Moment of Inertia in beam design can have dire consequences.

Structural Failure

If a beam’s Area Moment of Inertia is insufficient for the applied loads, the beam may deflect excessively, leading to aesthetic problems or functional impairment. In more severe cases, it can lead to structural failure.

This failure can manifest as yielding (permanent deformation) or fracture (complete separation of the material).

Over-Engineering and Inefficiency

Conversely, overestimating the required Area Moment of Inertia results in over-engineered beams. This means using more material than necessary.

While this may guarantee structural integrity, it leads to increased costs, added weight, and potentially inefficient designs. It’s about striking the right balance.

The Importance of Accurate Calculations

Therefore, accurate calculation and application of Area Moment of Inertia are vital. It is essential for creating safe, efficient, and cost-effective beam designs. Engineering judgment, combined with a solid understanding of these principles, ensures structural safety and optimal performance.

Area Moment of Inertia does not directly represent the stress experienced by the beam, but it critically influences how stress is distributed throughout the cross-section. A larger Area Moment of Inertia means a greater resistance to bending, and therefore, a reduction in the maximum stress experienced by the material. The relationship is complex, but essentially, a stronger shape, defined by its Area Moment of Inertia, will distribute stress more effectively and withstand greater loads before reaching its yield point. Let’s turn our attention now to the practical side – how do we actually calculate this crucial property for common structural shapes?

Calculating Bending Moment Inertia: Common Shapes Demystified

Calculating the Bending Moment Inertia is a fundamental skill for any engineer involved in structural design. While complex shapes might require advanced techniques or software, understanding how to calculate it for common shapes is essential. Let’s demystify the process with step-by-step instructions and examples for rectangular, circular, I-shaped, and T-shaped beams.

Rectangular Beams

Rectangular beams are among the simplest, yet most commonly encountered structural elements. Their straightforward geometry makes calculating their Area Moment of Inertia relatively easy.

Formula for Rectangular Beams

The formula for calculating the Area Moment of Inertia (I) of a rectangular beam about its centroidal axis (an axis passing through the center of the rectangle) is:

I = (b

**h^3) / 12

Where:

- b = width of the rectangle

- h = height of the rectangle

Note: It’s crucial that ‘h’ is the dimension parallel to the axis about which you are calculating the Area Moment of Inertia. If the beam is oriented differently, you’ll need to adjust which dimension is ‘h’ and which is ‘b’.

Numerical Example

Let’s consider a rectangular beam with a width (b) of 100 mm and a height (h) of 200 mm. To calculate its Area Moment of Inertia:

I = (100 mm** (200 mm)^3) / 12

I = (100 mm

**8,000,000 mm^3) / 12

I = 66,666,666.67 mm^4

Therefore, the Area Moment of Inertia of this rectangular beam is approximately 66.67 x 10^6 mm^4. This value can then be used to predict deflection and stress under load.

Circular Beams

Circular beams, while less common than rectangular ones in some applications, are prevalent in shafts, axles, and other rotationally symmetric structures.

Formula for Circular Beams

The formula for calculating the Area Moment of Inertia (I) of a circular beam about its diameter is:

I = (π** d^4) / 64

Or, expressed in terms of radius (r), since d = 2r:

I = (π

**r^4) / 4

Where:

- d = diameter of the circle

- r = radius of the circle

Nuances in Calculation

Unlike rectangles, the Area Moment of Inertia of a circle is the same about any axis passing through its center. This is due to its perfect symmetry. There’s no need to worry about which dimension is "height" or "width." However, be careful when dealing with hollow circular sections (tubes). The calculation is slightly more complex, involving subtracting the Area Moment of Inertia of the inner circle from that of the outer circle.

Numerical Example

Consider a circular beam with a diameter of 50 mm (radius of 25 mm). Let’s calculate its Area Moment of Inertia:

I = (π** (25 mm)^4) / 4

I = (π

**390,625 mm^4) / 4

I ≈ 306,796.15 mm^4

The Area Moment of Inertia of this circular beam is approximately 306.8 x 10^3 mm^4.

I-Beams and T-Beams

I-beams and T-beams represent a step up in complexity. These shapes are commonly used in construction due to their excellent strength-to-weight ratio. Calculating their Area Moment of Inertia requires breaking them down into simpler rectangular components and applying the Parallel Axis Theorem.

Breaking Down Complex Shapes

The key to tackling I-beams and T-beams (and other complex shapes) is to divide them into simpler, recognizable shapes – typically rectangles. Calculate the Area Moment of Inertia of each individual rectangle about its own centroidal axis. Then, use the Parallel Axis Theorem to find the Area Moment of Inertia of each rectangle about the overall centroidal axis of the entire composite shape.

Applying the Parallel Axis Theorem

The Parallel Axis Theorem states:

I = I

_c + Ad^2

Where:

- I = Area Moment of Inertia about the desired axis

- I_c = Area Moment of Inertia about the centroidal axis of the shape

- A = Area of the shape

- d = distance between the centroid of the shape and the desired axis

This theorem is essential because it allows us to "shift" the Area Moment of Inertia from a local centroid to a global centroid. It is used to compute the moment of inertia of an area about any axis parallel to the centroidal axis.

Example Calculations (I-Beam)

Let’s outline the general steps for an I-Beam (a full numerical example would be lengthy, but this provides the methodology):

- Divide the I-beam: Divide the I-beam into three rectangles: the top flange, the web, and the bottom flange.

- Calculate individual Areas and Centroids: Calculate the area and centroid location for each rectangle.

- Determine the overall Centroid: Determine the location of the overall centroid of the I-beam. This is often along the vertical axis of symmetry.

- Calculate Ic for each Rectangle: Calculate the Area Moment of Inertia (Ic) of each rectangle about its own centroidal axis (using the b**h^3/12 formula).

- Apply Parallel Axis Theorem: For each rectangle, calculate the distance (d) between its centroid and the overall centroid of the I-beam. Apply the Parallel Axis Theorem to find the Area Moment of Inertia of each rectangle about the overall centroidal axis.

- Sum the Moments of Inertia: Sum the Area Moments of Inertia of all three rectangles (calculated in the previous step) to find the total Area Moment of Inertia of the I-beam.

The process for a T-beam is similar, but involves only two rectangular components and may require a bit more calculation to find the overall centroid location, as it will not always be along an axis of symmetry as in the case of the I-Beam.

Mastering these calculations for common shapes provides a solid foundation for understanding the behavior of beams under bending and allows for more informed and efficient structural design.

The Parallel and Perpendicular Axis Theorems: Essential Tools

Having established the methods for calculating Bending Moment Inertia for basic shapes, we now need tools to tackle more complex geometries. The Parallel and Perpendicular Axis Theorems provide precisely that – a way to determine the Bending Moment Inertia of a shape about any axis, provided we know its Bending Moment Inertia about a centroidal axis. These theorems are indispensable for analyzing composite sections, opening the door to a wider range of structural designs.

Parallel Axis Theorem: Shifting the Reference Point

The Parallel Axis Theorem is used to calculate the Area Moment of Inertia of a shape about an axis that is parallel to its centroidal axis. This is crucial because often, the axis of interest for a structural calculation isn’t conveniently located at the centroid.

Unveiling the Theorem

In essence, the Parallel Axis Theorem states that the Area Moment of Inertia about any axis parallel to the centroidal axis is equal to the Area Moment of Inertia about the centroidal axis plus the product of the area of the shape and the square of the distance between the two axes.

This allows us to find the Bending Moment Inertia around a new axis without having to perform a full integration.

The Formula

The mathematical representation of the Parallel Axis Theorem is as follows:

I = Ic + Ad2

Where:

- I = Area Moment of Inertia about the new axis

- Ic = Area Moment of Inertia about the centroidal axis

- A = Area of the shape

- d = Distance between the centroidal axis and the new axis

Illustrative Examples

Let’s consider a rectangular beam with a hole drilled through it. To calculate the Area Moment of Inertia of the entire section about its base, we can:

-

Calculate the Area Moment of Inertia of the entire rectangle about its base.

-

Calculate the Area Moment of Inertia of the hole about its centroidal axis.

-

Use the Parallel Axis Theorem to shift the Area Moment of Inertia of the hole to the base of the rectangle.

-

Subtract the Area Moment of Inertia of the hole (about the base of the rectangle) from the Area Moment of Inertia of the entire rectangle (about its base).

This example clearly shows how the Parallel Axis Theorem simplifies complex calculations.

Another application can be seen in finding the moment of inertia of an I-beam section. The I-beam consists of multiple rectangular sections. The parallel axis theorem can be used to calculate the moment of inertia of the flanges about the neutral axis of the entire I-beam.

When Does It Apply?

The Parallel Axis Theorem is always applicable when you need to find the Area Moment of Inertia about an axis parallel to the centroidal axis. However, it’s crucial to remember that Ic must be the Area Moment of Inertia about the centroid. If it isn’t, the theorem won’t yield the correct result.

It cannot be used to find the Area Moment of Inertia about an axis that is not parallel to a centroidal axis without first rotating your coordinate system.

Perpendicular Axis Theorem: A 2D Limitation

The Perpendicular Axis Theorem provides a method for determining the Area Moment of Inertia of a planar (2D) shape about an axis perpendicular to the plane, given the Area Moments of Inertia about two perpendicular axes lying in the plane.

Explaining the Theorem

The Perpendicular Axis Theorem states that the Area Moment of Inertia about an axis perpendicular to the plane (often called the polar moment of inertia, J) is equal to the sum of the Area Moments of Inertia about two perpendicular axes lying in the plane.

The Formula

The Perpendicular Axis Theorem is mathematically expressed as:

J = Ix + Iy

Where:

- J = Polar Moment of Inertia about the z-axis (perpendicular to the plane)

- Ix = Area Moment of Inertia about the x-axis

- Iy = Area Moment of Inertia about the y-axis

Practical Examples

A common application is for circular shapes. Knowing the Area Moment of Inertia about the x and y axes (which are equal for a circle), we can easily find the polar moment of inertia.

For example, if Ix = Iy = πr4/4 for a circle of radius r, then J = πr4/2. This is crucial in calculating torsional stresses in shafts.

Applicability and Limitations

The key limitation of the Perpendicular Axis Theorem is that it only applies to planar (2D) objects. It cannot be used directly for 3D objects. Additionally, the axes Ix and Iy must be perpendicular to each other and lie in the same plane.

For 3-dimensional objects, the concept extends to calculating mass moment of inertia, but the perpendicular axis theorem in its original form does not apply.

By understanding and applying these theorems correctly, engineers can accurately calculate the Bending Moment Inertia for a wide range of complex shapes, leading to safer and more efficient structural designs.

Having equipped ourselves with the knowledge of calculating Bending Moment Inertia for various shapes and wielding the power of the Parallel and Perpendicular Axis Theorems, it’s time to see how these concepts translate into real-world structural engineering applications. Understanding how Bending Moment Inertia influences design decisions is crucial for ensuring the safety and efficiency of structures.

Bending Moment Inertia in Structural Engineering: Applications and Importance

Bending Moment Inertia is not merely an abstract calculation; it’s a cornerstone of structural engineering practice. It directly influences how engineers design beams, columns, and other structural elements to resist bending and prevent failure. By understanding its applications, we can appreciate its true significance in ensuring the integrity of buildings, bridges, and other infrastructure.

Beam Design and Bending Moment Inertia

Bending Moment Inertia plays a pivotal role in determining the load-bearing capacity and deflection characteristics of beams. When a beam is subjected to bending loads, it experiences internal stresses that resist deformation. The Bending Moment Inertia directly quantifies a beam’s resistance to bending.

A higher Bending Moment Inertia indicates a greater resistance to bending, which means the beam can withstand larger loads without excessive deflection or stress.

Structural engineers use Bending Moment Inertia to select appropriate beam sizes and shapes for specific applications, ensuring that the structure can safely support the intended loads.

Essentially, the required Bending Moment Inertia is determined by the applied loads and allowable deflection limits.

Radius of Gyration: Understanding Stability

The Radius of Gyration (r) provides a measure of how effectively a cross-sectional area resists buckling. It represents the distance from the centroidal axis at which the entire area of the cross-section can be assumed to be concentrated to produce the same Bending Moment Inertia. In simpler terms, it describes the distribution of an object’s cross-sectional area around its centroidal axis.

The formula for the radius of gyration is:

r = √(I/A)

Where:

- r = Radius of Gyration

- I = Bending Moment Inertia

- A = Cross-sectional area

The Radius of Gyration is particularly important in column design. Columns are structural members subjected to compressive axial loads. The higher the Radius of Gyration, the more stable the column is against buckling under compressive loads.

A larger Radius of Gyration implies a more compact cross-section, which is more resistant to buckling. Engineers use the Radius of Gyration to determine the appropriate size and shape of columns to prevent instability.

Section Modulus: Resisting Bending Stress

Section Modulus (S) is a geometric property of a cross-section that relates its Bending Moment Inertia to its extreme fiber distance. It essentially indicates a beam’s resistance to bending stress.

The formula for Section Modulus is:

S = I/y

Where:

- S = Section Modulus

- I = Bending Moment Inertia

- y = Distance from the neutral axis to the outermost fiber of the section

A higher Section Modulus indicates a greater capacity to resist bending stress. This means the beam can withstand larger bending moments without exceeding its allowable stress limits.

Relationship Between Section Modulus and Bending Moment Inertia

Section Modulus is directly derived from Bending Moment Inertia. It represents the Bending Moment Inertia normalized by the distance to the extreme fiber.

This relationship highlights the fundamental importance of Bending Moment Inertia in determining a structural member’s resistance to bending. Engineers use Section Modulus to calculate the maximum bending stress in a beam under a given load, ensuring that it remains within safe limits.

Having equipped ourselves with the knowledge of calculating Bending Moment Inertia for various shapes and wielding the power of the Parallel and Perpendicular Axis Theorems, it’s time to see how these concepts translate into real-world structural engineering applications. Understanding how Bending Moment Inertia influences design decisions is crucial for ensuring the safety and efficiency of structures.

Advanced Applications and Tools for Bending Moment Inertia

Bending Moment Inertia, while fundamentally a geometric property, forms the bedrock of more advanced analytical techniques used in structural engineering. Euler-Bernoulli Beam Theory and Finite Element Analysis (FEA) represent two powerful approaches that rely heavily on a precise understanding and application of Bending Moment Inertia. Additionally, awareness of common pitfalls in its calculation and application is essential for avoiding costly errors.

Euler-Bernoulli Beam Theory: A Foundation for Structural Analysis

Euler-Bernoulli beam theory, often referred to as elementary beam theory or engineer’s beam theory, provides a simplified method for calculating the load-carrying and deflection characteristics of beams.

This theory makes several key assumptions, including that plane sections remain plane during bending, and that deflections are small relative to the beam’s length.

Core Principles of Euler-Bernoulli Theory

The theory connects the applied bending moment to the beam’s curvature and the material’s elastic modulus. The Bending Moment Inertia (I) enters the equations directly, quantifying the beam’s resistance to bending deformation.

In essence, Euler-Bernoulli beam theory allows engineers to predict how a beam will respond to a given load, based on its geometry (including its Bending Moment Inertia) and material properties.

Limitations of Euler-Bernoulli Theory

It’s crucial to recognize that the Euler-Bernoulli theory has limitations. It is generally unsuitable for:

- Short, stubby beams where shear deformations become significant (Timoshenko beam theory is more appropriate in these cases).

- Beams with large deflections.

- Beams with complex loading conditions or geometries.

Bending Moment Inertia’s Role in the Theory

Despite its limitations, the Euler-Bernoulli theory remains a valuable tool for preliminary design and analysis, especially when a quick, approximate solution is needed. The accuracy of the theory heavily depends on the accurate determination of the Bending Moment Inertia.

Finite Element Analysis (FEA): A Powerful Computational Tool

Finite Element Analysis (FEA) is a numerical technique used to simulate the behavior of complex structures under various loading conditions.

FEA software divides a structure into smaller elements and uses numerical methods to solve the governing equations for each element. These equations incorporate material properties, boundary conditions, and, crucially, Bending Moment Inertia.

FEA Simulations and Bending Moment Inertia

Within FEA simulations, the Bending Moment Inertia of each element directly influences its stiffness and its response to applied loads. A structure with a higher Bending Moment Inertia will exhibit greater stiffness and resist deformation more effectively.

FEA allows engineers to analyze structures with complex geometries, material properties, and loading conditions that are beyond the scope of simpler analytical methods like Euler-Bernoulli beam theory.

Advantages and Disadvantages of FEA

FEA offers numerous advantages, including:

- The ability to model complex geometries and material behaviors.

- The ability to simulate various loading conditions.

- The ability to visualize stress and strain distributions within a structure.

However, FEA also has disadvantages:

- It can be computationally expensive, especially for large and complex models.

- The accuracy of the results depends on the quality of the model and the input data.

- Requires specialized software and expertise.

Common Mistakes to Avoid

Accurate calculation and application of Bending Moment Inertia are crucial for reliable structural analysis and design. Several common mistakes can lead to significant errors:

-

Incorrect Units: Using inconsistent units can lead to errors of several orders of magnitude. Always double-check that all values are expressed in consistent units (e.g., mm4, in4).

-

Misapplication of the Parallel Axis Theorem: Forgetting to account for the distance between the centroid of a composite shape’s components and the overall centroid can lead to a gross overestimation or underestimation of the Bending Moment Inertia.

-

Neglecting Section Properties: Failing to consider the actual cross-sectional shape and dimensions of a structural element can lead to inaccurate calculations.

-

Incorrectly Assuming Symmetry: Assuming symmetry where it does not exist can lead to simplified calculations that do not accurately represent the structure’s behavior.

-

Ignoring Stress Concentrations: While Bending Moment Inertia helps determine overall bending resistance, it doesn’t account for local stress concentrations that can occur at sharp corners or other geometric discontinuities.

Tips for Avoiding Errors:

-

Always double-check your calculations and units.

-

Use reliable software or online calculators to verify your results.

-

Carefully consider the assumptions underlying the chosen analytical method.

-

Seek a second opinion from a colleague or experienced engineer.

By understanding the advanced applications of Bending Moment Inertia and being aware of common mistakes, engineers can utilize this fundamental concept to design safe, efficient, and reliable structures.

Real-World Examples: Bending Moment Inertia in Action

Having equipped ourselves with the knowledge of calculating Bending Moment Inertia for various shapes and wielding the power of the Parallel and Perpendicular Axis Theorems, it’s time to see how these concepts translate into real-world structural engineering applications. Understanding how Bending Moment Inertia influences design decisions is crucial for ensuring the safety and efficiency of structures.

Let’s delve into some concrete examples that illustrate the profound impact of accurate Bending Moment Inertia calculations, and the potential pitfalls of neglecting this critical parameter.

Case Study 1: The Hyatt Regency Walkway Collapse

One of the most tragic and well-documented examples highlighting the critical importance of accurate structural calculations is the Hyatt Regency walkway collapse in Kansas City, Missouri, in 1981. This disaster serves as a stark reminder of the devastating consequences of seemingly minor errors in engineering design.

The Design Flaw

The original design for the suspended walkways called for the support rods to pass directly through the upper walkway and connect to the lower walkway. However, a design change was implemented where the upper walkway’s support rods were connected only to the roof, and the lower walkway was hung from the upper walkway’s support rods.

This seemingly small alteration doubled the load on the connection between the upper walkway and its support rods.

Consequences of Underestimation

The revised design effectively halved the Bending Moment Inertia (and consequently the load-bearing capacity) of the connection point.

On July 17, 1981, during a tea dance, the overloaded connection failed, causing both walkways to collapse onto the crowded lobby below.

The collapse resulted in 114 deaths and over 200 injuries, making it one of the deadliest structural failures in US history.

Lessons Learned

The Hyatt Regency walkway collapse underscores the critical importance of thoroughly reviewing and recalculating structural designs whenever any modification is made.

Even seemingly minor changes can have significant impacts on load distribution and structural integrity. It also highlights the need for clear communication and collaboration between engineers, architects, and contractors to ensure that designs are correctly interpreted and implemented.

Case Study 2: The Burj Khalifa: A Triumph of Engineering

In stark contrast to the Hyatt Regency disaster, the Burj Khalifa in Dubai stands as a testament to the power of accurate and innovative structural engineering. Its groundbreaking design and record-breaking height required meticulous attention to detail, including precise calculations of Bending Moment Inertia.

Overcoming Wind Loads

One of the major challenges in designing the Burj Khalifa was mitigating the effects of wind loads on such a tall structure.

The engineers employed a unique "Y" shaped floor plan, which disrupts wind flow and reduces wind forces on the building.

Optimizing Structural Performance

The shape also maximizes the building’s Bending Moment Inertia, providing exceptional resistance to bending and twisting under high wind conditions.

Careful analysis and optimization of the building’s geometry were essential to ensure its stability and prevent excessive sway. The Bending Moment Inertia was a key factor in these calculations.

Material Selection and Innovation

The Burj Khalifa’s construction also involved the use of high-strength concrete and advanced construction techniques.

These innovations allowed the engineers to create a structure that was both strong and lightweight, further optimizing its resistance to wind loads and minimizing the overall weight of the building.

A Success Story

The Burj Khalifa stands as a symbol of engineering excellence, demonstrating how a deep understanding and application of structural principles, including Bending Moment Inertia, can lead to the creation of groundbreaking and iconic structures.

The Importance of Accuracy and Consequences of Errors

These two case studies vividly illustrate the critical importance of accuracy in Bending Moment Inertia calculations and structural design in general.

Accuracy is Paramount

Inaccurate calculations can lead to underestimation of stress, deflection, and overall load-bearing capacity.

This can result in structural failure, as seen in the Hyatt Regency walkway collapse, with potentially catastrophic consequences.

Consequences Extend Beyond Safety

The consequences of errors extend beyond safety.

Inaccurate calculations can also lead to inefficient designs, resulting in wasted materials, increased construction costs, and reduced structural performance.

The Role of Software and Peer Review

Modern engineering software can greatly assist in performing complex calculations and simulations.

However, it is crucial to remember that software is only a tool, and the engineer remains responsible for verifying the accuracy of the results and ensuring that the design meets all applicable codes and standards.

Peer review is also a crucial aspect of ensuring accuracy and identifying potential errors in design calculations.

A fresh set of eyes can often catch mistakes that the original engineer may have overlooked.

In conclusion, Bending Moment Inertia is not just a theoretical concept. It is a fundamental parameter that directly impacts the safety, efficiency, and performance of real-world structures. A thorough understanding and accurate application of this concept are essential for all engineers involved in structural design.

FAQs: Mastering Bending Moment Inertia

Here are some frequently asked questions to help clarify concepts discussed in "Master Bending Moment Inertia: The Ultimate Guide!".

What exactly is bending moment inertia?

Bending moment inertia, often just called moment of inertia in the context of beams and bending, is a geometric property of a cross-section that indicates how effectively it resists bending caused by applied forces. A higher bending moment inertia means the cross-section is more resistant to bending.

How is bending moment inertia different from just regular "inertia"?

Regular inertia refers to an object’s resistance to changes in translational motion (moving in a straight line). Bending moment inertia, on the other hand, describes resistance to rotational motion specifically induced by bending forces. They’re both related to an object’s resistance to change, but in different ways.

Why is understanding bending moment inertia so important for structural design?

Understanding bending moment inertia is crucial because it directly impacts how a beam or structural member will deform under load. If the bending moment inertia is insufficient, the structure could deflect excessively or even fail.

How do I calculate bending moment inertia for complex shapes?

For complex shapes, you typically divide the shape into simpler geometric components (rectangles, triangles, circles, etc.). Then, you calculate the bending moment inertia of each individual component and use the parallel axis theorem to find the total bending moment inertia for the entire shape about the desired axis.

So there you have it! Hopefully, this ultimate guide helped you get a solid handle on bending moment inertia. Now go forth and build stuff (safely, of course!).