Achieving optimal performance in your Kohler engine often hinges on mastering Kohler carburetor troubleshooting. The efficiency of the carburetor directly impacts engine power. Proper maintenance ensures longevity. Understanding the role of the idle circuit, the fuel mixture screws, and the carburetor float is vital for preventing common issues. This guide provides a clear pathway to diagnosing and resolving Kohler carburetor troubleshooting challenges, ensuring your equipment runs smoothly.

Mastering Kohler Carburetor Troubleshooting: A Step-by-Step Guide

This guide aims to simplify Kohler carburetor troubleshooting. Forget frustrating repair attempts; this structured approach, focusing on common issues and clear solutions, will help you diagnose and fix your carburetor efficiently.

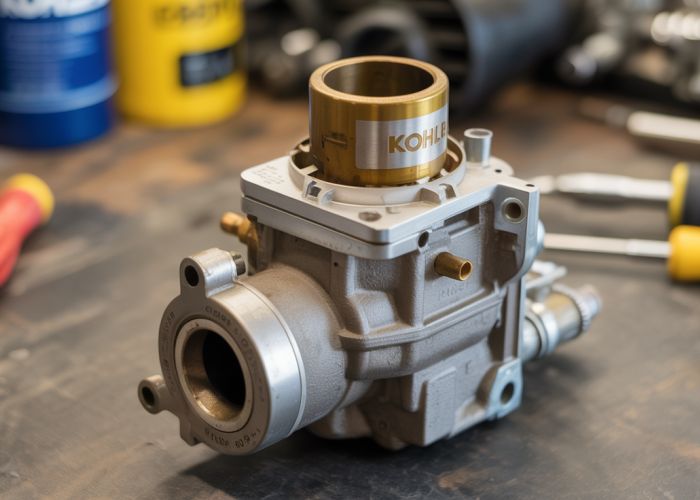

1. Understanding the Basics of a Kohler Carburetor

Before diving into troubleshooting, it’s crucial to understand the fundamental components and function of a Kohler carburetor.

- Function: The carburetor’s primary role is to mix fuel and air in the correct ratio for optimal combustion within the engine.

- Key Components:

- Float Bowl: Holds the fuel supply.

- Float: Regulates fuel level within the float bowl.

- Main Jet: Delivers fuel at higher engine speeds.

- Pilot Jet: Provides fuel at idle and low speeds.

- Throttle Valve: Controls airflow into the engine.

- Choke Valve: Enriches the fuel mixture for cold starting.

2. Identifying Common Kohler Carburetor Problems

Effective troubleshooting starts with correctly identifying the symptoms. Here are some common problems you might encounter:

- Engine Won’t Start: Could indicate a lack of fuel or an incorrect fuel-air mixture.

- Rough Idling: Often caused by a clogged pilot jet or improper idle speed adjustment.

- Engine Stalling: Can be due to fuel starvation or a faulty float.

- Black Smoke: Indicates an overly rich fuel mixture (too much fuel, not enough air).

- White Smoke: Usually signifies burning oil or coolant, but can sometimes be related to a lean fuel mixture in cold conditions.

- Poor Performance at High Speed: A blocked main jet is a likely culprit.

3. Essential Tools and Safety Precautions

Before you start any work, gather the necessary tools and prioritize safety.

- Tools:

- Socket set and wrenches

- Screwdrivers (Phillips and flathead)

- Carburetor cleaner

- Small brushes or picks for cleaning jets

- Compressed air (optional but helpful)

- Safety glasses

- Gloves

- Safety Precautions:

- Work in a well-ventilated area. Carburetor cleaner and gasoline fumes are flammable and harmful.

- Disconnect the spark plug wire to prevent accidental starting.

- Wear safety glasses and gloves to protect your eyes and skin.

- Dispose of used fuel and cleaning materials properly.

4. Step-by-Step Kohler Carburetor Troubleshooting Guide

This section provides a structured approach to diagnose and fix common carburetor problems.

4.1 Checking the Fuel Supply

- Is there fuel in the tank? Sounds obvious, but it’s the first thing to check!

- Is the fuel fresh? Old fuel can become stale and cause issues. Drain the old fuel and replace it with fresh fuel.

- Is the fuel filter clogged? Replace the fuel filter if it appears dirty or restricted.

- Is the fuel line blocked or damaged? Check for kinks, cracks, or obstructions in the fuel line.

4.2 Examining the Float and Float Bowl

- Is the float sticking? A sticking float can prevent fuel from entering the carburetor. Gently manipulate the float to ensure it moves freely.

- Is the float damaged or punctured? A damaged float may sink, leading to flooding. Replace the float if necessary.

- Is the float level correct? The float level affects the fuel mixture. Consult your engine’s service manual for the correct float level specification.

- Is the float bowl clean? Remove the float bowl and clean it thoroughly with carburetor cleaner.

4.3 Inspecting and Cleaning the Jets

- Identify the Main and Pilot Jets: These are typically small brass screws or plugs located in the carburetor body.

- Remove the Jets: Carefully remove the jets, noting their positions.

- Clean the Jets: Use carburetor cleaner and a small wire or brush to clear any obstructions in the jet orifices.

- Reinstall the Jets: Ensure the jets are securely tightened but avoid over-tightening.

4.4 Checking the Choke and Throttle

- Choke Operation: Ensure the choke plate opens and closes fully. Check the choke linkage for proper adjustment.

- Throttle Operation: Verify the throttle valve moves smoothly throughout its range of motion.

- Throttle Linkage: Inspect the throttle linkage for any binding or damage.

4.5 Adjusting the Idle Speed

- Locate the Idle Speed Screw: This screw typically adjusts the position of the throttle valve at idle.

- Adjust the Screw: Turn the screw to achieve the correct idle speed, as specified in your engine’s service manual.

- Fine-Tune: Make small adjustments until the engine idles smoothly without stalling.

5. Utilizing Troubleshooting Tables

Sometimes, a structured table can help pinpoint issues faster.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | No fuel, clogged jets, spark issue | Check fuel supply, clean jets, check spark plug and ignition system |

| Rough Idle | Clogged pilot jet, incorrect idle speed adjustment | Clean pilot jet, adjust idle speed screw |

| Engine Stalling | Fuel starvation, faulty float | Check fuel lines and filter, inspect and replace float if necessary |

| Black Smoke | Rich fuel mixture, faulty choke | Adjust carburetor, check choke operation and linkage |

| Poor High-Speed Performance | Clogged main jet | Clean or replace main jet |

This table provides a starting point, but further investigation might be needed depending on your specific situation.

Kohler Carburetor Fix: FAQs

Here are some frequently asked questions about fixing your Kohler carburetor and avoiding future issues.

What are the most common symptoms of a dirty Kohler carburetor?

Common symptoms include difficulty starting, rough idling, stalling, black smoke from the exhaust, and a general lack of power, especially under load. These issues often stem from a build-up of deposits restricting fuel flow. Knowing these signs can help you catch problems early and prevent more serious damage. If you are experiencing these, kohler carburetor troubleshooting is the first step.

What’s the easiest way to clean a Kohler carburetor without taking it completely apart?

While a complete disassembly allows for the most thorough cleaning, you can try using a carburetor cleaner spray. Spray the cleaner into the carburetor throat while the engine is running (or attempting to start). This might dissolve some of the build-up, but remember, this is often a temporary fix. For lasting results, you need to address the root cause of the buildup.

What are some preventative maintenance steps I can take to avoid future Kohler carburetor problems?

Use fresh, high-quality fuel and consider adding a fuel stabilizer, especially during storage. Regularly check and replace your fuel filter. Avoid letting your engine sit for extended periods with fuel in the carburetor. These simple steps go a long way in preventing kohler carburetor troubleshooting situations.

When should I consider replacing my Kohler carburetor instead of trying to fix it?

If your carburetor is severely damaged, has cracks, or repeatedly clogs even after thorough cleaning, replacement is often the most cost-effective solution. Also, if you notice the carburetor body is warped or the throttle shaft is excessively worn, it is often more reliable to replace rather than repair.

Alright, you’ve got the know-how to tackle most Kohler carburetor troubleshooting issues now! Go get ’em, and happy tinkering!