Understanding the fcc unit cell is fundamental in materials science. The packing efficiency, a crucial attribute, significantly impacts material properties. Cubic crystal structures, a broader class, include the fcc unit cell as a notable example. Metallurgists at MIT, renowned for their materials research, often analyze fcc unit cell structures to optimize alloy performance. The concept of atomic packing factor, a measurable quantity, describes the density within the fcc unit cell. This guide comprehensively explains the intricacies of the fcc unit cell and its significance in various applications.

In the vast landscape of materials science and metallurgy, understanding the underlying structure of materials is paramount. The arrangement of atoms at the microscopic level dictates a material’s macroscopic properties, influencing everything from its strength and ductility to its electrical conductivity and corrosion resistance. Among the various crystal structures found in nature and engineered materials, the Face-Centered Cubic (FCC) structure stands out due to its prevalence and its impact on material behavior.

The Significance of Crystal Structures

Crystal structures are the very foundation upon which the properties of materials are built. They define how atoms are arranged in a solid, and this arrangement dictates how the material will respond to external forces, heat, electricity, and other environmental factors.

Understanding crystal structures allows us to:

-

Predict and control material properties.

-

Design new materials with specific characteristics.

-

Optimize existing materials for enhanced performance.

The Ubiquitous FCC Structure

The Face-Centered Cubic (FCC) structure is one of the most common crystal structures found in metals. Its prevalence stems from its relatively efficient packing of atoms, leading to desirable properties such as ductility and malleability. Many technologically important metals, including aluminum, copper, gold, silver, nickel, and platinum, crystallize in the FCC structure.

The FCC structure’s impact extends far beyond these pure metals. It also forms the basis for many important alloys and compounds. The understanding of FCC structures is thus, indispensable in the field of material science.

Purpose of This Guide

This comprehensive guide aims to provide a detailed understanding of the FCC unit cell. We will delve into its atomic arrangement, key characteristics, and its influence on material properties.

By the end of this guide, you will have a solid foundation in:

-

Understanding the fundamental principles of the FCC structure.

-

Identifying FCC materials and their applications.

-

Appreciating the role of the FCC structure in materials science and engineering.

The understanding of FCC structures is thus, indispensable in the field of material science.

Now that we’ve highlighted the significance of crystal structures and the specific prevalence of the FCC arrangement, it’s time to delve into the specifics. What exactly defines this fundamental building block of materials, and how does its unique atomic arrangement contribute to the properties we observe?

What is the FCC Unit Cell? A Deep Dive

Before we can fully appreciate the intricacies of the Face-Centered Cubic (FCC) unit cell, we must first establish a clear understanding of the broader concepts that underpin it: crystal structures and unit cells. These foundational ideas provide the necessary context for comprehending the specific characteristics of the FCC arrangement.

Defining Crystal Structure

A crystal structure describes the ordered arrangement of atoms, ions, or molecules in a crystalline solid.

This arrangement is not random; it’s a highly organized, repeating pattern that extends in three dimensions. This periodicity is what gives crystalline materials their characteristic properties, distinguishing them from amorphous materials, which lack long-range order.

The specific type of crystal structure a material adopts significantly influences its mechanical, electrical, thermal, and optical properties. Understanding crystal structures is, therefore, essential for predicting and controlling material behavior.

The Concept of a Unit Cell

The unit cell is the smallest repeating unit that possesses the full symmetry of the crystal structure.

Imagine a three-dimensional wallpaper pattern; the unit cell is the smallest section of that wallpaper that, when repeated in all directions, recreates the entire pattern.

By understanding the arrangement of atoms within the unit cell, we can deduce the entire crystal structure. Unit cells are defined by their lattice parameters: the lengths of the cell edges (a, b, c) and the angles between them (α, β, γ).

These parameters dictate the size and shape of the unit cell, which, in turn, influences the material’s properties.

Decoding the FCC Unit Cell: Atomic Arrangement and Location

The Face-Centered Cubic (FCC) unit cell is a specific type of cubic unit cell characterized by atoms located at each of the eight corners of the cube and at the center of each of the six faces.

This arrangement results in a highly symmetrical and relatively close-packed structure.

Arrangement of Atoms: The FCC unit cell has atoms at each corner and in the center of each face.

Location of Atoms: Each corner atom is shared by eight adjacent unit cells, so only 1/8 of each corner atom belongs to a specific unit cell.

Each face-centered atom is shared by two adjacent unit cells, so 1/2 of each face-centered atom belongs to a specific unit cell.

To calculate the total number of atoms per FCC unit cell:

(8 corners 1/8 atom/corner) + (6 faces 1/2 atom/face) = 1 + 3 = 4 atoms.

Therefore, an FCC unit cell contains a total of 4 atoms.

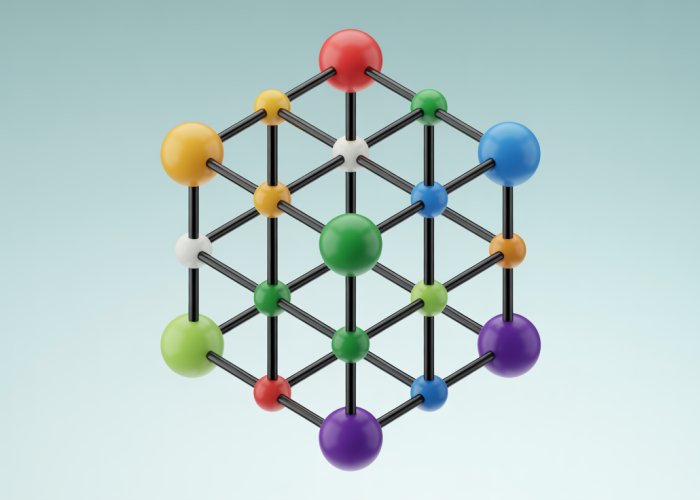

Visualizing the FCC Structure

Understanding the spatial arrangement of atoms in the FCC unit cell is greatly enhanced by visual aids. Diagrams and illustrations provide a clear representation of the atomic positions and their relationship to the overall structure.

These visuals often depict the unit cell as a cube with atoms at the corners and face centers, allowing for easy identification of the key features of the FCC arrangement.

(Include diagrams and illustrations of the FCC Unit Cell here)

The understanding of FCC structures is thus, indispensable in the field of material science.

Now that we’ve highlighted the significance of crystal structures and the specific prevalence of the FCC arrangement, it’s time to delve into the specifics. What exactly defines this fundamental building block of materials, and how does its unique atomic arrangement contribute to the properties we observe?

Key Characteristics: Lattice Constant, Coordination Number, and APF

The Face-Centered Cubic (FCC) unit cell possesses distinct characteristics that govern the behavior of materials adopting this structure. These include the lattice constant, coordination number, and atomic packing factor (APF). Each plays a crucial role in determining the physical and mechanical properties of FCC metals and alloys.

Lattice Constant and Atomic Radius

The lattice constant, denoted as ‘a’, is a fundamental parameter that defines the size of the unit cell. It represents the length of the edge of the cube. In the FCC structure, the lattice constant is directly related to the atomic radius (r) of the constituent atoms.

This relationship arises from the fact that atoms touch each other along the face diagonal of the cube. Through geometric calculations, it can be shown that for an FCC structure:

a = 2√2

**r

This equation is of paramount importance. It allows us to calculate the lattice constant if we know the atomic radius or vice versa. This interrelation is crucial in understanding how the size of atoms influences the overall dimensions of the crystal lattice.

Coordination Number: Neighbors Matter

The coordination number is another essential characteristic. It defines the number of nearest neighbors an atom has within the crystal structure. In simpler terms, it tells us how many atoms are directly touching a given atom.

For the FCC structure, the coordination number is 12. This high coordination number is a direct consequence of the efficient packing of atoms in the FCC arrangement. Each atom is surrounded by twelve equidistant neighbors, contributing to the overall stability and density of the structure.

The high coordination number in FCC structures has significant implications. It directly influences properties such as ductility and the ability of the material to deform plastically without fracturing.

Atomic Packing Factor (APF): Efficiency of Packing

The Atomic Packing Factor (APF) quantifies the fraction of space occupied by atoms within the unit cell. It is a dimensionless number, ranging from 0 to 1, that indicates how efficiently atoms are packed in a crystal structure.

A higher APF implies a denser structure, with atoms occupying a larger proportion of the available space.

Defining and Calculating APF

The APF is defined as the ratio of the volume of atoms in the unit cell to the total volume of the unit cell:

APF = (Volume of atoms in the unit cell) / (Total volume of the unit cell)

To calculate the APF for the FCC unit cell, we need to consider the following:

- Number of atoms per unit cell: In the FCC structure, there are effectively 4 atoms per unit cell. This is because there are 8 corner atoms (each contributing 1/8 of an atom to the unit cell) and 6 face-centered atoms (each contributing 1/2 of an atom). Therefore, (8 1/8) + (6 1/2) = 4 atoms.

- Volume of each atom: Assuming atoms are spherical, the volume of each atom is (4/3)πr³, where r is the atomic radius.

- Total volume of the unit cell: The volume of the cube is a³, where ‘a’ is the lattice constant.

Substituting a = 2√2 r into the volume equation we have a³ = (2√2 r)³ = 16√2** r³

Thus, the APF for the FCC structure can be calculated as follows:

APF = (4 (4/3)πr³) / (16√2 r³) = π / (3√2) ≈ 0.74

This result indicates that approximately 74% of the space in an FCC unit cell is occupied by atoms, making it a relatively densely packed structure.

The Role of Ions in FCC Structures

While the discussion so far has centered on atoms in FCC structures, it is important to acknowledge the role of ions. In ionic compounds, the FCC arrangement can also be adopted. Here, the lattice points are occupied by positively charged cations and negatively charged anions.

The arrangement of ions in the FCC lattice, and the charge balance between the ions, dictates the overall stability and properties of the ionic compound. Examples include sodium chloride (NaCl) which adopts an FCC structure.

Understanding how these ions interact and are arranged within the FCC framework is crucial. It allows to predict and tailor the properties of a wide range of ionic materials.

The atomic packing factor and coordination number provide a theoretical understanding of how efficiently atoms are arranged within the FCC lattice. But what does this mean for the real world? Which materials actually adopt this structure, and how do the theoretical properties translate into tangible characteristics that we can observe and utilize?

FCC Materials: Examples and Their Properties

The Face-Centered Cubic structure isn’t just a theoretical construct; it’s a common arrangement found in numerous metals that form the backbone of countless industries. Understanding which metals crystallize in this manner, and how that influences their behavior, is essential for materials selection and engineering design. Let’s explore some prominent examples.

Common FCC Metals

Several well-known metals adopt the FCC structure. This includes:

- Aluminum (Al)

- Copper (Cu)

- Gold (Au)

- Silver (Ag)

- Nickel (Ni)

- Platinum (Pt)

These metals, due to their FCC arrangement, share some common traits. However, the subtle differences in their atomic radii and electronic configurations lead to a spectrum of properties, making each uniquely suited for specific applications.

Properties Dictated by the FCC Structure

The FCC crystal structure significantly impacts the properties of these metals, influencing their mechanical, electrical, and thermal behaviors.

Ductility and Malleability

A hallmark of FCC metals is their high ductility and malleability. This stems from the close-packed planes within the FCC structure. These planes allow for easy slip and deformation under stress. This makes these metals amenable to processes like drawing, rolling, and forging without fracturing.

Electrical Conductivity

Many FCC metals, particularly copper, silver, and gold, exhibit excellent electrical conductivity. The close-packed structure facilitates the easy movement of electrons through the material. This makes them ideal for electrical wiring, connectors, and other electronic components.

Corrosion Resistance

Some FCC metals, like gold and platinum, are known for their exceptional corrosion resistance. Their inert nature prevents them from readily reacting with the environment. This makes them suitable for applications where long-term durability and resistance to degradation are crucial, such as in jewelry, dental implants, and specialized chemical processing equipment.

Applications of FCC Metals

The unique combination of properties stemming from the FCC structure makes these metals indispensable in various applications.

Aluminum

Aluminum’s lightweight nature, coupled with good strength and corrosion resistance, makes it a staple in the aerospace, automotive, and packaging industries. It’s used in aircraft fuselages, beverage cans, and structural components.

Copper

Copper’s high electrical conductivity makes it the go-to material for electrical wiring and components. It is also widely used in plumbing due to its corrosion resistance and thermal conductivity.

Gold and Silver

These precious metals find applications in jewelry, coinage, and electronics. Their inertness and high conductivity are invaluable in specialized electronic components and plating.

Nickel

Nickel is often used as an alloying element to enhance the strength and corrosion resistance of other metals, particularly steel. It is also used in batteries and as a catalyst in chemical reactions.

Platinum

Platinum’s exceptional catalytic properties and corrosion resistance make it essential in catalytic converters for automobiles. It is also used in jewelry, laboratory equipment, and medical implants.

The Significance and Real-World Applications of FCC Structures

We’ve seen that specific metals tend to adopt the FCC structure, and how their atomic arrangement dictates certain theoretical characteristics.

But the true impact of the Face-Centered Cubic structure becomes apparent when we examine how it shapes the real-world properties and applications of materials. From the ease with which metals can be shaped to their ability to conduct electricity, the FCC arrangement plays a pivotal role.

Mechanical Properties: Ductility, Malleability, and Strength

One of the most significant impacts of the FCC structure is on the mechanical behavior of metals. FCC metals are renowned for their ductility and malleability. These properties, which describe a material’s ability to deform under tensile stress (ductility) and compressive stress (malleability) without fracturing, are directly linked to the FCC crystal lattice.

The close-packed planes within the FCC structure—specifically the {111} planes—allow for the easy movement of dislocations. Dislocations are line defects in the crystal lattice, and their movement is the primary mechanism by which metals deform plastically.

The presence of multiple close-packed planes and directions within these planes provides numerous avenues for dislocation motion, facilitating significant plastic deformation before failure.

This is in stark contrast to other crystal structures, like the Body-Centered Cubic (BCC) structure at lower temperatures, which have fewer easily accessible slip systems, leading to more brittle behavior.

While FCC metals excel in ductility and malleability, their strength—the resistance to deformation—is also influenced by the crystal structure, but in a more complex way.

The ease of dislocation motion, while beneficial for ductility, can lead to lower strength in pure FCC metals. However, various strengthening mechanisms, such as solid solution strengthening (alloying), work hardening (cold working), and grain size refinement, can be employed to enhance the strength of FCC metals while retaining a reasonable level of ductility.

Electrical Conductivity: Structure-Property Correlation

The FCC structure also influences the electrical conductivity of metals. Metals conduct electricity because of the presence of delocalized electrons, which can move freely through the crystal lattice.

The electronic band structure, which describes the allowed energy levels for electrons in a solid, is influenced by the arrangement of atoms in the crystal lattice.

FCC metals generally exhibit high electrical conductivity due to the favorable electronic band structure, which allows for efficient electron transport.

For example, copper, silver, and gold, all FCC metals, are among the best electrical conductors known. Their FCC structure contributes to the high mobility of electrons, making them ideal for electrical wiring, contacts, and other electronic applications.

The presence of defects and impurities in the crystal lattice can scatter electrons, reducing conductivity. Therefore, the purity and structural perfection of FCC metals are crucial for achieving optimal electrical performance.

Other Relevant Properties

Beyond mechanical and electrical properties, the FCC structure can also influence corrosion resistance and magnetic behavior.

Corrosion Resistance

Some FCC metals, such as platinum and gold, exhibit excellent corrosion resistance. This is primarily due to their inert nature and the formation of a passive oxide layer on their surface, which protects the underlying metal from further oxidation.

The FCC structure itself does not directly dictate corrosion resistance, but it can influence the formation and stability of protective surface layers.

Magnetic Properties

The magnetic properties of FCC metals are more complex and depend on the specific element and its electronic configuration.

Some FCC metals, such as nickel, are ferromagnetic, meaning they can exhibit spontaneous magnetization. Ferromagnetism arises from the alignment of electron spins within the material, which is influenced by the electronic band structure and atomic arrangement.

Other FCC metals, such as copper and aluminum, are non-magnetic. The magnetic properties of FCC alloys can be tailored by varying the composition and processing conditions, leading to a wide range of magnetic materials for various applications.

The properties we’ve explored so far, such as ductility and electrical conductivity, clearly demonstrate the significant impact of the FCC structure. However, to truly appreciate the nuances of the Face-Centered Cubic arrangement, it’s essential to place it within the context of other common crystal structures. How does the FCC stack up against alternatives like Simple Cubic and Body-Centered Cubic? What are the trade-offs inherent in each structure, and how do these differences manifest in material behavior? Let’s delve into a comparative analysis.

FCC vs. Other Unit Cell Structures: A Comparative Analysis

The Face-Centered Cubic (FCC) structure is just one of several ways atoms can arrange themselves in a crystalline solid. To fully understand its characteristics, it’s helpful to compare it to other common unit cell structures, namely the Simple Cubic (SC) and Body-Centered Cubic (BCC) structures. Each of these arrangements dictates different material properties and suitability for specific applications.

Simple Cubic (SC): A Basic Arrangement

The Simple Cubic structure is the most basic arrangement, with atoms located only at the corners of the cube.

This results in a relatively open structure with atoms not closely packed.

Key Characteristics of Simple Cubic

-

Coordination Number: The coordination number in SC is 6, meaning each atom has six nearest neighbors.

-

Atomic Packing Factor (APF): The APF for SC is approximately 0.52, indicating that only about 52% of the space is occupied by atoms. This is the lowest APF compared to FCC and BCC.

-

Properties and Examples: Due to its low packing efficiency, the SC structure is relatively rare in metals. Polonium is one of the few elements that exhibits this structure. SC structures generally exhibit lower strength and are less ductile compared to FCC and BCC metals.

Body-Centered Cubic (BCC): Increased Packing Efficiency

The Body-Centered Cubic structure features atoms at each corner of the cube, with an additional atom at the center of the cell. This central atom increases the packing efficiency compared to the Simple Cubic structure.

Key Characteristics of Body-Centered Cubic

-

Coordination Number: The coordination number in BCC is 8, reflecting the presence of the central atom which increases the number of nearest neighbors.

-

Atomic Packing Factor (APF): The APF for BCC is approximately 0.68, a significant improvement over the SC structure, but still lower than FCC.

-

Properties and Examples: Many metals, such as iron (at room temperature), chromium, and tungsten, exhibit the BCC structure. BCC metals generally possess high strength and moderate ductility. However, at lower temperatures, BCC metals can become brittle, as their slip systems are not as readily available as in FCC structures.

Contrasting FCC with SC and BCC: A Detailed Comparison

The FCC structure stands out when compared directly with SC and BCC structures. Its higher APF and unique slip systems contribute to distinct material properties.

Atomic Packing Factor (APF)

-

FCC APF: The FCC structure boasts an APF of 0.74, indicating the most efficient packing of atoms among the three structures.

-

SC APF: As mentioned earlier, SC has the lowest APF at 0.52.

-

BCC APF: BCC falls in between with an APF of 0.68.

The higher APF in FCC implies greater density and, often, improved stability.

Coordination Number

-

FCC Coordination Number: FCC has a coordination number of 12, the highest among the three structures.

-

SC Coordination Number: SC has the lowest coordination number of 6.

-

BCC Coordination Number: BCC has a coordination number of 8.

A higher coordination number generally leads to stronger interatomic bonding and increased stability.

Mechanical Properties

-

FCC: FCC metals are known for their excellent ductility and malleability. This is due to the numerous close-packed planes that facilitate dislocation movement.

-

SC: SC structures are typically brittle and weak due to the limited number of slip systems.

-

BCC: BCC metals offer a balance of strength and ductility, although they can become brittle at low temperatures.

Other Properties

The crystal structure also influences other properties such as electrical conductivity, thermal expansion, and corrosion resistance. FCC metals generally exhibit good electrical conductivity and corrosion resistance.

The arrangement of atoms in the FCC structure significantly influences its material properties. By comparing it with simpler arrangements like Simple Cubic and Body-Centered Cubic, we gain a deeper appreciation for the trade-offs inherent in each structure and how these differences dictate their suitability for various engineering applications.

FCC Unit Cell FAQs

Have more questions about the Face-Centered Cubic (FCC) unit cell? Here are some common queries to help you better understand its structure and properties.

What exactly defines an FCC unit cell?

An FCC unit cell is a type of cubic unit cell where, in addition to atoms at all eight corners of the cube, there are also atoms centered on each of the six faces. These face-centered atoms are key to the unique properties of the fcc unit cell.

How many atoms are there within an FCC unit cell?

While there are atoms at each corner and face, they are shared with adjacent unit cells. After accounting for this sharing, there are effectively 4 atoms per fcc unit cell.

What are some common examples of materials with an FCC structure?

Several common metals crystallize in an FCC structure. Examples include aluminum, copper, gold, and silver. These metals exhibit properties closely linked to their fcc unit cell arrangement.

How does the FCC structure affect material properties?

The face-centered cubic structure leads to properties such as high ductility and malleability. The close-packed arrangement of atoms in the fcc unit cell allows for easier deformation without fracture.

Alright, that wraps up our deep dive into the fascinating world of the fcc unit cell! Hopefully, you’ve got a solid grasp on things now. Go forth and conquer those crystal structures!