Material science, specifically concerning steel structures, depends heavily on understanding how stress affects various materials. Engineers at ASTM International, known for setting standards, often need to define elastic limit for different alloys, ensuring structural integrity. That threshold, crucial for determining a material’s resilience, prevents permanent deformation, a key factor studied using tools like a universal testing machine.

Defining the Elastic Limit: Understanding Material Behavior

This article layout explains the concept of the elastic limit, aiming for a clear and comprehensive understanding. The primary focus is to define elastic limit in a way that is both informative and easy to grasp.

Introduction: The Elastic Realm

Begin by introducing the idea of elasticity. Discuss how materials deform under stress and, more importantly, how they often return to their original shape when the stress is removed. This sets the stage for understanding the elastic limit.

- Hooke’s Law Briefly Introduced: Mention the basic relationship between stress and strain, providing context. This doesn’t need to be an in-depth explanation but rather a lead-in to the limitations of this relationship.

- Everyday Examples: Give relatable examples of elastic behavior, like stretching a rubber band or bending a ruler slightly.

What Does It Mean to Define Elastic Limit?

This is the core of the article. Provide a precise and easily understandable definition.

Defining the Point of No Return

- The elastic limit is the maximum stress a solid material can withstand before undergoing permanent deformation.

- Beyond this point, the material will not return to its original shape after the stress is removed; it will exhibit plastic deformation.

- Use a simple analogy: Imagine a spring. Stretching it slightly allows it to return to its original length. But stretching it too far will permanently deform it. The elastic limit is the point just before that permanent deformation occurs.

Technical Definition (Optional)

If you choose to include a more technical definition, keep it clear and concise.

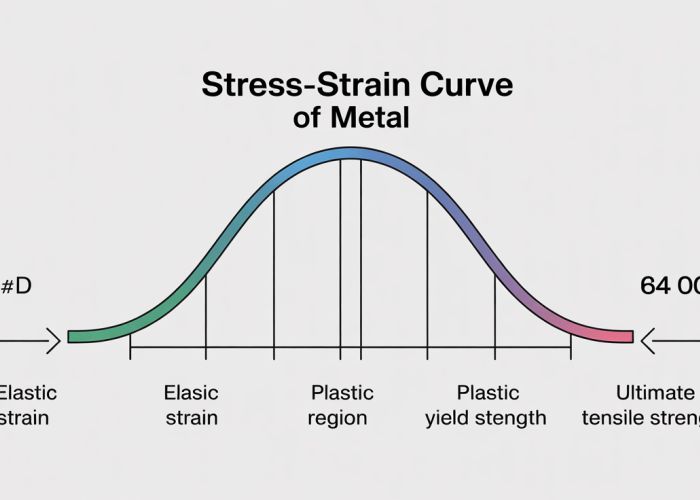

- The stress value on a stress-strain curve where the linear relationship ends and the material starts to deviate from Hooke’s Law.

- Emphasize that this point is often approximated.

Understanding the Difference: Elastic vs. Plastic Deformation

This section clarifies the distinction between elastic and plastic behavior.

-

Elastic Deformation:

- Reversible.

- Material returns to its original shape after stress removal.

- Energy is typically stored and released (e.g., a spring).

-

Plastic Deformation:

- Irreversible.

- Material retains a permanent change in shape.

- Energy is dissipated as heat and other forms.

-

Visual Representation: A simple graphic comparing elastic and plastic deformation would be highly beneficial here.

Factors Affecting the Elastic Limit

Discuss factors that can influence a material’s elastic limit.

- Material Type: Different materials have drastically different elastic limits.

- Example: Steel has a much higher elastic limit than rubber.

- Temperature: Higher temperatures generally lower the elastic limit.

- Explain how increased atomic vibrations weaken the material’s resistance to deformation.

- Manufacturing Processes: Processes like cold working can alter the elastic limit.

- Explain how work hardening can increase the elastic limit by introducing dislocations in the material structure.

- Loading Conditions: The type of stress applied (tension, compression, shear) can influence the observed elastic limit.

- A material might have a different elastic limit in tension compared to compression.

The Elastic Limit vs. Yield Strength vs. Proportional Limit

Clearly distinguish between these related but different concepts. A table can be effective here:

| Property | Definition | Key Difference |

|---|---|---|

| Elastic Limit | The maximum stress before permanent deformation. | The theoretical point where elasticity ends; difficult to measure precisely. |

| Yield Strength | The stress at which a specified amount of permanent deformation occurs (typically 0.2% offset). | A practical measure of the onset of plastic deformation; easier to determine experimentally. |

| Proportional Limit | The stress up to which stress is directly proportional to strain (Hooke’s Law applies). | The point beyond which the stress-strain relationship is no longer linear. Always less than or equal to the elastic limit. |

Practical Applications and Implications

Explain why understanding the elastic limit is important in engineering and other fields.

- Structural Design: Ensuring structures don’t undergo permanent deformation under load.

- Material Selection: Choosing appropriate materials based on their elastic properties for specific applications.

- Manufacturing Processes: Optimizing processes to avoid exceeding the elastic limit and causing damage.

- Safety Considerations: Avoiding catastrophic failures by staying within the elastic limits of materials.

Measuring the Elastic Limit

Briefly touch on methods used to determine the elastic limit.

- Tensile Testing: Describe the basic process of stretching a material and measuring the stress-strain relationship.

- Stress-Strain Curve Analysis: Explain how the elastic limit is identified on a stress-strain curve (although it is usually approximated by the yield strength). Mention the limitations in directly pinpointing the elastic limit.

FAQs: Understanding the Elastic Limit

Have questions about the elastic limit? Here are some common inquiries to help clarify this crucial material property.

What exactly is the elastic limit?

The elastic limit is the maximum stress a solid material can withstand without undergoing permanent deformation. In simpler terms, it’s the point beyond which the material won’t return to its original shape after the stress is removed. To define elastic limit, it marks the transition from elastic (recoverable) behavior to plastic (permanent) behavior.

How does the elastic limit differ from the yield strength?

The elastic limit and yield strength are often close but technically different. The elastic limit is the point where permanent deformation begins. Yield strength is the stress that produces a specified amount of permanent deformation (e.g., 0.2% offset). If no permanent deformation can be measured at the elastic limit, they may be considered the same for practical purposes.

What happens if a material is stressed beyond its elastic limit?

Once the elastic limit is exceeded, the material undergoes plastic deformation. This means even after the stress is removed, the material will retain a permanent change in shape. This can lead to weakening of the material and potential failure under subsequent loading.

Why is understanding the elastic limit important in engineering?

Knowing the elastic limit of a material is vital for designing structures and components. Engineers use this information to ensure that materials are used within their elastic range, preventing permanent deformation and ensuring the long-term integrity and safety of the design. Using materials beyond what define elastic limit can lead to catastrophic failures.

So, there you have it – that’s pretty much what it means to define elastic limit! Hope this explanation helps you understand the concept a little better. Now go forth and impress your friends (or at least survive your next engineering class)!