Successfully drilling cast iron hinges on understanding several crucial aspects. Improper speed selection on your drill press, a common tool for this task, can lead to rapid tool wear. Choosing the right cutting fluid is also paramount; its use helps dissipate heat and ensures a cleaner cut. Moreover, understanding the properties of cast iron itself, a metal known for its brittleness, is essential in preventing cracks and breaks during the process. Finally, safety precautions, like wearing eye protection, need to be followed to make sure that you are kept safe.

Drilling Cast Iron: A Comprehensive Guide to Success

Successfully drilling cast iron requires understanding its unique properties and adapting your techniques accordingly. This guide helps you avoid common mistakes and achieve clean, accurate holes.

Understanding Cast Iron for Drilling

Cast iron is a brittle material with high carbon content. This makes it prone to chipping and cracking if not drilled correctly. Knowing the type of cast iron you’re working with (gray, ductile, etc.) can be helpful, but the fundamental principles remain the same. The goal is to minimize stress and heat build-up during the drilling process.

Types of Cast Iron

While differentiating between types requires more advanced knowledge, understanding their general characteristics helps:

- Gray Cast Iron: Most common type. Known for its good machinability due to the graphite flakes within its structure. Relatively brittle.

- Ductile Cast Iron (Nodular Cast Iron): Stronger and more ductile than gray cast iron. Offers better impact resistance.

- White Cast Iron: Extremely hard and brittle. Difficult to machine.

- Malleable Cast Iron: Heat-treated to improve ductility.

Essential Tools and Materials

Having the right tools significantly improves the outcome when drilling cast iron.

- Drill Press (Recommended): Provides greater stability and control compared to a handheld drill.

- High-Speed Steel (HSS) Drill Bits: Suitable for general-purpose drilling of cast iron. Cobalt drill bits offer improved heat resistance and longer life. Carbide-tipped drill bits are best for harder cast irons and high-volume drilling.

- Cutting Fluid/Lubricant (Important!): Specialized cutting fluids designed for cast iron are ideal. However, if those are not available, use kerosene, light machine oil, or even a dry drilling method. DO NOT use water-based coolants.

- Center Punch and Hammer: Used to create a starting point for the drill bit, preventing it from wandering.

- Clamps or Vise: Securely holds the workpiece in place.

- Safety Glasses: Essential for protecting your eyes from flying debris.

- Work Gloves: Provides a better grip and protects your hands.

Preparing for Drilling

Proper preparation is crucial to prevent issues later in the process.

Securing the Workpiece

Clamping the cast iron piece is the first step. A vise is preferable, especially when using a drill press. Ensure the piece is rigidly supported to prevent vibrations.

Marking the Drilling Location

- Use a ruler or measuring tape to accurately locate the desired hole position.

- Mark the spot clearly with a pencil or marker.

- Using a center punch and hammer, create a small indentation at the marked point. This provides a stable starting point for the drill bit and prevents it from skating across the surface.

Choosing the Right Drill Bit

Select a drill bit appropriate for the desired hole size. Ensure the drill bit is sharp. A dull bit will cause excessive heat and increase the risk of cracking the cast iron. Consider using a set of drill bits to work your way up to the desired size in stages.

The Drilling Process: Step-by-Step

Follow these steps carefully for optimal results when drilling cast iron.

-

Secure the Drill Bit: Firmly insert the drill bit into the drill chuck and tighten it securely.

-

Set the Drill Speed: Cast iron requires a slow drilling speed. Adjust the drill press or handheld drill to a low RPM setting. Refer to this general guideline:

Drill Bit Diameter (Inches) Recommended Speed (RPM) 1/8" – 1/4" 800 – 1200 1/4" – 1/2" 400 – 800 1/2" – 3/4" 200 – 400 3/4" – 1" 100 – 200 These speeds are approximate and may need to be adjusted based on the specific cast iron and drill bit type.

-

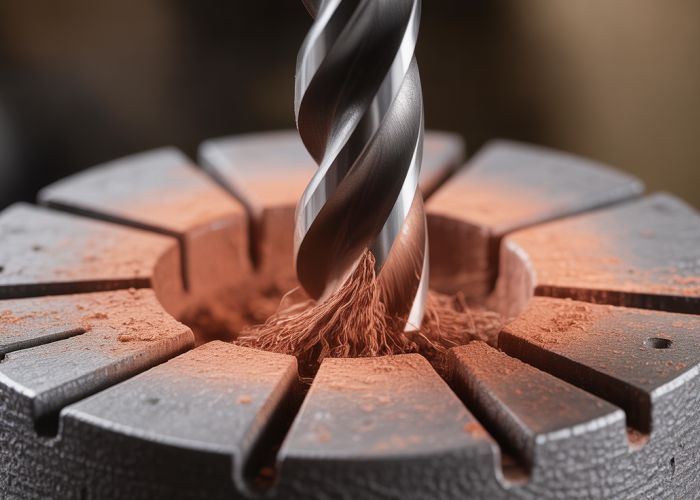

Apply Cutting Fluid/Lubricant: Apply a small amount of cutting fluid to the marked drilling location. Reapply throughout the drilling process to keep the bit cool and lubricated. As mentioned earlier, dry drilling can be considered as an alternative if you are uncomfortable using cutting fluid and have the right setup.

-

Start Drilling: With the workpiece securely clamped, carefully align the drill bit with the center-punched indentation. Apply steady, even pressure to the drill. Avoid forcing the bit, let the drill do the work.

-

Drill in Stages (Especially for Larger Holes): For larger holes, consider drilling a pilot hole first with a smaller drill bit. This helps guide the larger bit and reduces the risk of wandering or chipping. Gradually increase the drill bit size until the desired hole diameter is achieved.

-

Clear Chips Frequently: As you drill, regularly remove the drill bit to clear away any accumulated chips. This prevents the chips from packing into the hole and causing excessive heat or binding.

-

Reduce Pressure as You Exit: As the drill bit nears the backside of the cast iron, reduce the pressure to prevent breakout or chipping. It’s better to slow down and create a clean exit than to rush and damage the material.

Troubleshooting Common Issues

Even with careful preparation, problems can arise. Here are some common issues and their solutions:

- Drill Bit Wandering: Ensure the center punch indentation is deep and precise. Start with a slow speed and apply steady pressure.

- Excessive Heat: Reduce the drilling speed and apply more cutting fluid. Check the drill bit for sharpness.

- Chipping or Cracking: Reduce drilling pressure, especially near the exit point. Use a sharper drill bit. Clamp the workpiece securely to minimize vibrations.

- Drill Bit Binding: Clear chips frequently and ensure the hole is properly lubricated. Check the drill bit for damage.

Alternative Techniques for Drilling Cast Iron

While the above method is most common, other techniques exist for specific scenarios:

-

Step Drill Bits: Designed for creating holes in thin materials, they can be used on cast iron if the thickness is appropriate. They provide clean, burr-free holes.

-

Hole Saws: Used for creating large-diameter holes. Require a slow speed and steady pressure. Ensure the cast iron is securely clamped.

-

Laser Cutting: While not "drilling," laser cutting is an option for complex shapes and precise cuts in cast iron, although it’s typically used for thinner sections.

Drilling Cast Iron FAQs

Here are some frequently asked questions to help you understand the nuances of drilling cast iron effectively and safely.

Why is drilling cast iron different from drilling steel?

Cast iron is brittle and prone to cracking if not drilled carefully. It also produces a unique dust that can be messy. Drilling cast iron requires slower speeds and different techniques compared to drilling steel to prevent damage.

What’s the best drill bit for drilling cast iron?

High-speed steel (HSS) drill bits are a good starting point. Cobalt drill bits are even better due to their increased hardness and heat resistance. Carbide-tipped bits are the most durable option for drilling cast iron, especially for larger holes.

Do I need cutting fluid when drilling cast iron?

No, cutting fluid isn’t necessary and is generally discouraged when drilling cast iron. It can actually trap the swarf and create a paste that reduces cutting efficiency and increases friction. It’s best to drill dry and remove the swarf frequently.

What speed should I use when drilling cast iron?

A slower speed is crucial for drilling cast iron. Start with a low RPM and gradually increase it until you achieve a smooth, controlled cut. Excessive speed can lead to overheating and cracking of the cast iron.

So, go ahead and tackle that drilling cast iron project! Just remember these tips, and you’ll be well on your way to a smooth and successful outcome. Happy drilling!