Achieving a flawless finish on Douglas Fir, known for its distinctive grain, requires a blend of technique and the right products. The characteristics of this wood, often used in rustic interior design, can be enhanced dramatically with the correct staining approach. Expert finishers at the Fine Woodworking Association often recommend careful surface preparation to ensure even color absorption when working with douglas fir stained projects. Many woodworkers find that understanding the specific attributes of Douglas Fir is key to a perfect stain.

Douglas Fir Stained: Secrets to a Perfect Finish Revealed!

Achieving a beautiful, lasting finish on Douglas fir wood can be a rewarding experience. While this softwood can sometimes present challenges due to its grain and tendency to absorb stain unevenly, following a structured approach will lead to professional-looking results. Let’s explore the best article layout to guide readers through the process of staining Douglas fir successfully.

Introduction: Setting the Stage for Success

The introduction should immediately grab the reader’s attention and highlight the benefits of staining Douglas fir.

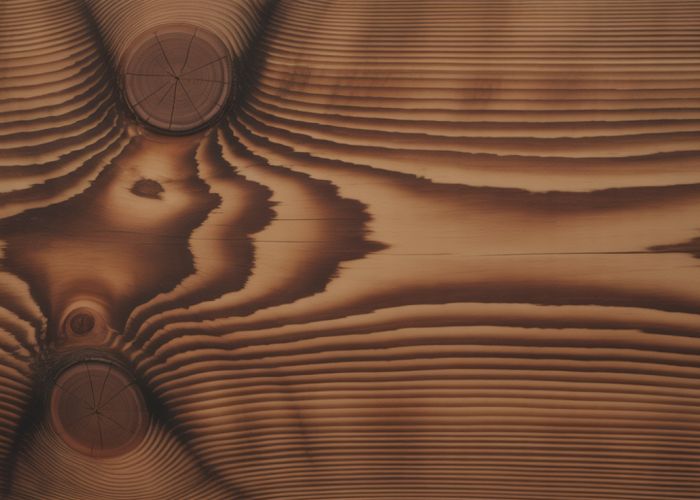

- Hook: Start with a visually appealing image of perfectly stained Douglas fir. This could be a furniture piece, trim, or any project showcasing the wood’s beauty after staining.

- Problem Statement: Acknowledge the challenges of staining Douglas fir, such as uneven absorption and blotchiness. Reassure readers that these issues can be overcome with proper techniques.

- Solution Overview: Briefly outline the key steps and techniques discussed in the article. This provides a roadmap for the reader and encourages them to continue.

- Benefits Highlight: Mention the advantages of a well-stained Douglas fir project, such as enhancing its natural beauty, increasing its durability, and protecting it from the elements.

Preparation is Key: Setting Yourself Up for Success

Proper preparation is crucial for any staining project, especially with Douglas fir.

Surface Preparation: Ensuring a Smooth Canvas

- Cleaning: Explain the importance of removing dirt, dust, and debris from the wood surface. Recommend using a tack cloth or a mild cleaner.

- Sanding: Detail the sanding process, including grit progression (e.g., starting with 120-grit, moving to 180-grit, and finishing with 220-grit). Emphasize the importance of sanding in the direction of the grain.

- Wood Conditioner (Optional): Discuss the benefits of using a wood conditioner or pre-stain treatment to help even out stain absorption. Explain how wood conditioners work and recommend suitable products for Douglas fir.

- Dust Removal: Reiterate the importance of removing all sanding dust before applying stain.

Choosing the Right Stain: Making an Informed Decision

Selecting the appropriate stain is critical for achieving the desired look and performance.

Stain Types: Oil-Based vs. Water-Based

- Oil-Based Stains: Discuss the advantages of oil-based stains, such as deeper penetration, richer color, and longer working time. Mention potential drawbacks like longer drying times and stronger odors.

- Water-Based Stains: Highlight the benefits of water-based stains, including lower VOCs, faster drying times, and easy cleanup. Address potential challenges like raising the grain and requiring more coats for desired color depth.

Color Selection: Achieving Your Desired Aesthetic

- Understanding Undertones: Explain how the natural undertones of Douglas fir can affect the final stain color.

- Testing Stains: Strongly recommend testing stain samples on scrap pieces of Douglas fir before applying it to the entire project. This allows readers to visualize the final color and make adjustments if needed.

- Color Charts and Swatches: Encourage readers to use color charts and swatches as a starting point, but emphasize the importance of testing due to variations in wood grain and absorption.

Application Techniques: Mastering the Art of Staining

The application method greatly impacts the final appearance of the stained Douglas fir.

Application Methods: Brushing, Rags, and Spraying

- Brushing: Describe the proper brushing technique, emphasizing long, even strokes in the direction of the grain. Recommend using a high-quality brush for a smooth finish.

- Rags: Explain how to apply stain using a clean, lint-free rag. Highlight the importance of wiping off excess stain to prevent blotching.

- Spraying: Discuss the advantages of spraying, such as even coverage and faster application. Mention the need for proper ventilation and safety precautions.

Wiping Techniques: Achieving Consistent Color

- Even Application: Stress the importance of applying stain evenly across the entire surface.

- Wiping Excess: Explain how to wipe off excess stain within a specific timeframe (e.g., 5-10 minutes) to prevent uneven color and tackiness.

- Directional Wiping: Emphasize the importance of wiping in the direction of the grain for a natural-looking finish.

Drying Times: Patience is a Virtue

- Recommended Drying Times: Provide general guidelines for drying times based on the type of stain used (oil-based vs. water-based).

- Environmental Factors: Explain how temperature and humidity can affect drying times.

- Testing for Dryness: Recommend testing the stained surface for dryness before applying a topcoat.

Topcoat Protection: Enhancing Durability and Longevity

A topcoat protects the stained surface and enhances its durability.

Types of Topcoats: Varnish, Polyurethane, Lacquer

- Varnish: Discuss the advantages of varnish, such as its durability and resistance to moisture.

- Polyurethane: Highlight the benefits of polyurethane, including its hardness, scratch resistance, and ease of application.

- Lacquer: Explain the advantages of lacquer, such as its fast drying time and smooth finish. Mention the need for proper ventilation and safety precautions.

Application of Topcoat: Achieving a Flawless Finish

- Sanding: Lightly sand the stained surface with fine-grit sandpaper (e.g., 320-grit) to create a smooth base for the topcoat.

- Cleaning: Remove all sanding dust before applying the topcoat.

- Application: Apply the topcoat in thin, even coats using a brush, spray gun, or applicator pad.

- Drying: Allow the topcoat to dry completely according to the manufacturer’s instructions.

- Sanding (Optional): Lightly sand between coats for an even smoother finish.

- Repeat: Apply multiple coats for enhanced protection and durability.

Troubleshooting: Addressing Common Issues

Even with careful planning, problems can arise. This section will address common issues.

Blotchy Staining: Identifying and Resolving the Issue

- Causes: Explain the causes of blotchy staining, such as uneven wood density and inadequate surface preparation.

- Solutions: Recommend solutions for addressing blotchy staining, such as using a wood conditioner, sanding more thoroughly, and applying a tinted topcoat.

Uneven Color: Achieving Consistent Results

- Causes: Explain the causes of uneven color, such as improper application techniques and variations in stain absorption.

- Solutions: Recommend solutions for achieving consistent color, such as applying multiple thin coats of stain, wiping off excess stain evenly, and using a pre-stain treatment.

Peeling or Chipping Finish: Preventing and Repairing Damage

- Causes: Explain the causes of peeling or chipping finishes, such as inadequate surface preparation, incompatible finishes, and exposure to moisture.

- Solutions: Recommend solutions for preventing and repairing peeling or chipping finishes, such as sanding thoroughly, using compatible finishes, and protecting the wood from the elements.

By following this layout and incorporating these details, you can create a comprehensive and informative article that empowers readers to successfully stain Douglas fir and achieve beautiful, lasting results.

Douglas Fir Stained: Frequently Asked Questions

Here are some common questions about staining Douglas fir, especially regarding achieving a professional and lasting finish.

Why is Douglas fir considered difficult to stain?

Douglas fir is a softwood with a significant difference between the hard, dense earlywood and the soft, porous latewood. This variation in density can cause stain to absorb unevenly, resulting in a blotchy or inconsistent finish. Properly prepping the wood before staining is crucial.

What is the best way to prep Douglas fir for stain?

Sanding is key. Start with a coarser grit (around 120) to even out the surface, then gradually move to finer grits (220-320) for a smooth finish. Applying a wood conditioner specifically designed for softwoods before staining can also help create a more uniform absorption of the douglas fir stained finish.

What type of stain works best on Douglas fir?

Gel stains are often recommended for douglas fir stained projects. They sit on the surface of the wood rather than penetrating deeply, minimizing blotchiness. Pigmented stains, which contain solid particles of pigment, can also provide more even color compared to dye stains. Oil-based stains often provide better results than water-based, as they tend to penetrate more evenly.

How many coats of stain should I apply to Douglas fir?

Generally, one coat of stain is sufficient for douglas fir stained projects if you’ve properly prepped the wood and are using a good quality stain. Applying multiple coats can darken the color, but also increase the risk of an uneven finish. Always test the stain on a scrap piece of Douglas fir first to ensure you achieve the desired color.

So, there you have it! All the secrets to getting that perfect douglas fir stained finish. Now go grab your brushes, and let’s make some woodworking magic happen!