The foundation of any successful electronics project lies in a well-equipped workspace, and creating your own electronic test bench offers unparalleled customization. Tektronix, a leading manufacturer of oscilloscopes, provides critical tools often found on a professional test bench. The ability to accurately measure voltage, current, and resistance is paramount, making a quality multimeter an indispensable component. For hobbyists delving into circuit design, having access to prototyping boards can drastically accelerate the development process. This article will guide you through designing and building your own dream electronic test bench, empowering you to tackle complex projects with ease.

For anyone delving into the world of electronics, whether as a seasoned professional or an enthusiastic hobbyist, the importance of a dedicated workspace cannot be overstated.

Imagine a surgeon operating without a sterile environment, or a chef creating a masterpiece in a disorganized kitchen. The same principle applies to electronics: a well-equipped and organized workspace, specifically an electronic test bench, is critical for success.

This article will guide you through the process of creating your own DIY electronic test bench, tailored to your specific needs and budget.

We’ll explore the advantages of such a personalized setup and provide a roadmap for building a workspace that fosters creativity, efficiency, and safety.

The Significance of a Dedicated Electronic Test Bench

Why is a dedicated space so crucial for electronics work? The answer lies in the nature of the work itself.

Electronics projects often involve intricate tasks, delicate components, and precise measurements.

A cluttered or shared workspace can lead to frustration, errors, and even damage to valuable equipment.

Enhanced Efficiency and Productivity

A dedicated electronic test bench provides a consistent and controlled environment.

Having all your tools and equipment readily available eliminates the time wasted searching for misplaced items.

Furthermore, a well-organized bench promotes a smoother workflow, allowing you to focus on the task at hand and boost your overall productivity.

Imagine the difference between trying to solder a tiny component on your kitchen table versus having a stable, well-lit bench with all your tools within easy reach.

The latter scenario dramatically reduces the risk of mistakes and improves the speed and quality of your work.

The DIY Advantage: Customization and Cost-Effectiveness

While commercially available test benches exist, the DIY approach offers significant advantages, primarily in terms of customization and cost.

One size rarely fits all.

A DIY bench allows you to tailor the workspace to your specific project requirements, the equipment you use, and your personal preferences.

Tailoring to Your Needs and Budget

Do you primarily work with microcontrollers? Or are you more interested in RF circuits?

Perhaps you need a large surface area for assembling complex projects, or a compact bench for working in a limited space.

A DIY approach allows you to design a bench that perfectly fits your needs.

Furthermore, building your own bench can be significantly more cost-effective than purchasing a pre-built model.

You can choose materials that fit your budget and avoid paying for features you don’t need.

The Satisfaction of Building

Beyond the practical benefits, there’s a unique satisfaction in building your own workspace.

Creating something with your own hands fosters a sense of ownership and connection to your work.

It also allows you to develop a deeper understanding of the tools and equipment you use, as well as the principles of ergonomics and workspace design.

Article Roadmap: A Step-by-Step Guide

This article will serve as your comprehensive guide to building your dream electronic test bench.

We’ll start with planning and design, helping you assess your needs, optimize your space, and prioritize ergonomics.

Next, we’ll delve into the essential equipment and tools you’ll need, from core measurement instruments like multimeters and oscilloscopes to basic hand tools and electronic components.

We’ll then provide a step-by-step guide to building the physical bench, covering material selection, equipment mounting, and lighting considerations.

Safety is paramount, so we’ll dedicate a section to ESD protection, electrical safety, and safe soldering practices.

Finally, we’ll cover organization and storage tips to help you maintain a tidy and efficient workspace, as well as basic testing and calibration steps to ensure the accuracy of your instruments.

Planning and Design: Laying the Foundation

The allure of diving headfirst into building your electronic test bench is understandable. However, resist the urge to immediately start assembling components. Careful planning and design are the cornerstones of a successful and satisfying build. This crucial stage involves more than just sketching a rough idea; it demands a thorough assessment of your needs, a strategic approach to space optimization, and a deep consideration of ergonomics. By investing time upfront, you will ensure a workspace that is not only functional but also comfortable, efficient, and perfectly tailored to your specific requirements.

Needs Assessment: Defining Your Project Requirements

The first step in planning your electronic test bench is to conduct a thorough needs assessment. This involves identifying the types of projects you anticipate working on. Are you primarily focused on microcontroller programming, analog circuit design, or RF communication projects? The answer to this question will dictate the necessary equipment, tools, and space requirements for your bench.

For example, someone working on high-frequency circuits will require an oscilloscope with a significantly higher bandwidth than someone primarily focused on low-frequency audio projects. Similarly, projects involving soldering surface mount components will necessitate a soldering station with precise temperature control and potentially a hot air rework station.

Consider the scale of your projects as well. Will you be working with small, breadboard-based circuits, or larger, more complex systems? This will influence the amount of workspace required. Moreover, make a list of the specific equipment and tools you know you will need (e.g., multimeter, power supply, soldering iron, etc.), as well as any specialized items like a logic analyzer or spectrum analyzer, based on the types of projects you plan to undertake. Finally, don’t forget to factor in storage needs for components, tools, and documentation.

Space Optimization: Making the Most of Your Area

Once you have a clear understanding of your equipment and space requirements, it’s time to consider the physical layout of your test bench.

Begin by measuring your available space accurately.

Consider the dimensions of the room or area where you plan to set up your bench. Then, sketch out a rough layout, experimenting with different configurations to maximize workflow.

Think about the placement of your equipment. Instruments that you use frequently, such as your multimeter and power supply, should be easily accessible. Components and tools should be stored in a way that minimizes clutter and allows you to quickly find what you need.

Vertical space is often underutilized. Shelves and drawers can be valuable for storing components, tools, and documentation, freeing up valuable workspace on the benchtop. Also, consider the placement of power outlets and lighting fixtures. Ensure that you have adequate access to power and that your workspace is well-lit to prevent eye strain.

Optimizing workflow should be central to your design, ensuring that the layout promotes efficiency and reduces unnecessary movement.

Ergonomics: Comfort and Efficiency

Ergonomics is often overlooked in the design of an electronic test bench, but it is crucial for long-term comfort and productivity. Spending hours hunched over a workbench can lead to neck pain, back pain, and other musculoskeletal issues. By prioritizing ergonomics, you can create a workspace that is both comfortable and efficient.

Selecting the right workbench height is essential.

The ideal height will depend on your height and the type of work you will be doing. A general rule of thumb is that the workbench should be at a height that allows you to work with your elbows bent at a 90-degree angle. This will help to prevent strain on your back and shoulders.

Consider a workbench with adjustable height if possible. This allows you to fine-tune the height to your specific needs and preferences. The height of the chair should also be considered.

A comfortable chair with good lumbar support is essential for extended work sessions. Look for a chair with adjustable height, backrest, and armrests to ensure proper posture.

Consider using a footrest to further improve your posture and reduce strain on your legs. Additionally, ensure adequate lighting to minimize eye strain. Task lighting that can be positioned to illuminate your work area is ideal.

By prioritizing ergonomics, you can create a workspace that is not only functional but also comfortable and conducive to productivity. A well-designed test bench is an investment in your long-term health and well-being.

Planning and thoughtful design can lay a solid groundwork, but it’s the selection of the right tools that truly brings your electronic test bench to life. Like a painter needs their brushes or a chef their knives, the electronics enthusiast requires a carefully curated collection of equipment to bring their ideas to fruition. This next step involves assembling your arsenal, a set of core measurement instruments, essential hand tools, and a selection of fundamental electronic components. With the right gear at your disposal, you’ll be well-equipped to tackle any project that sparks your interest.

Essential Equipment and Tools: Your Arsenal for Success

An electronic test bench is only as good as the tools it houses. Selecting the right equipment can be the difference between a frustrating experience and a productive one. This section details the core measurement instruments, basic hand tools, and electronic components necessary for building a functional and versatile electronic test bench.

Core Measurement Instruments: Precision at Your Fingertips

These instruments are the cornerstones of any electronics workbench, allowing you to accurately measure and analyze circuit behavior. Investing in quality measurement tools is paramount for obtaining reliable data and ensuring project success.

Multimeter: The Indispensable Diagnostic Tool

The multimeter is arguably the most versatile and essential instrument on any electronic test bench. It’s your go-to tool for measuring voltage (AC and DC), current, and resistance.

Beyond these basic functions, many multimeters also offer continuity testing (identifying broken connections), diode testing, and even temperature measurements.

When choosing a multimeter, consider the following:

- Accuracy: Look for a multimeter with a specified accuracy rating that meets your project requirements.

- Resolution: A higher resolution allows for more precise readings, particularly when measuring small values.

- Features: Determine which additional features are important for your needs, such as auto-ranging, true RMS measurement, and data logging.

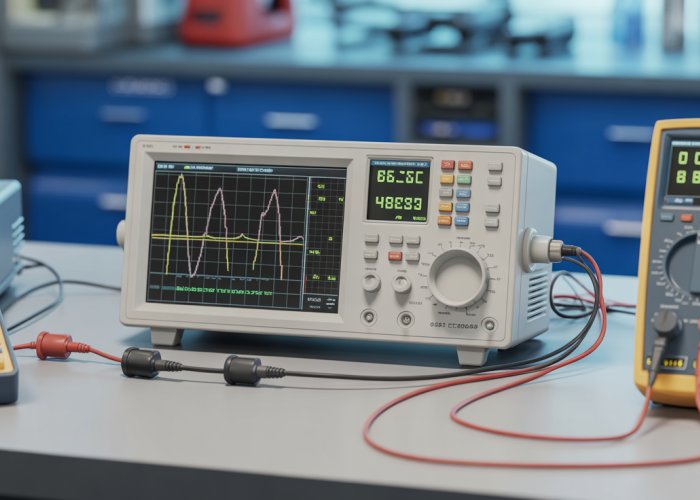

Oscilloscope: Visualizing Signals

The oscilloscope provides a visual representation of voltage signals over time, enabling you to analyze signal characteristics such as amplitude, frequency, and pulse width. It is an indispensable tool for debugging circuits, identifying signal distortion, and analyzing complex waveforms.

Key features to consider when selecting an oscilloscope include:

- Bandwidth: The bandwidth determines the maximum frequency signal the oscilloscope can accurately measure. Choose an oscilloscope with a bandwidth significantly higher than the highest frequency you anticipate working with.

- Sampling Rate: The sampling rate dictates how frequently the oscilloscope samples the input signal. A higher sampling rate is necessary for accurately capturing fast-changing signals.

- Triggering: Triggering allows you to stabilize the display by synchronizing the sweep with a specific point on the input signal. Look for oscilloscopes with versatile triggering options.

Power Supply: Supplying the Juice

A variable power supply provides a stable and adjustable source of DC voltage and current to power your circuits. It is essential for testing and prototyping, as it allows you to experiment with different voltage levels without risking damage to your components.

When selecting a power supply, consider:

- Voltage and Current Range: Choose a power supply that can provide the voltage and current levels required for your projects.

- Regulation: Look for a power supply with good voltage and current regulation to ensure a stable output even under varying load conditions.

- Protection Features: Over-voltage protection (OVP) and over-current protection (OCP) are crucial for protecting your circuits from damage.

Signal Generator: Creating Test Signals

A signal generator produces various waveforms, such as sine waves, square waves, and triangle waves, which are used for testing and analyzing circuit behavior. It is an invaluable tool for characterizing filter responses, testing amplifier performance, and simulating real-world signals.

Basic Hand Tools: The Foundation of Any Build

While advanced instruments are essential for analysis, a good set of hand tools is the foundation for any electronics project. These tools enable you to physically assemble, modify, and repair circuits.

Soldering Iron: Making the Connections

A soldering iron is used to create permanent electrical connections between components. Choosing the right soldering iron is crucial for achieving reliable and long-lasting solder joints.

Consider the following when selecting a soldering iron:

- Type: Soldering stations with adjustable temperature control are highly recommended for their versatility.

- Wattage: Higher wattage soldering irons heat up faster and are better suited for soldering larger components.

- Tip Style: Different tip styles are available for various soldering tasks. A conical tip is a good general-purpose option.

Wiring: Connecting the Dots

Selecting the appropriate wire gauge and type is crucial for ensuring reliable connections and preventing overheating. Different wires are appropriate for different applications.

- Solid core wire is generally used for breadboarding and point-to-point wiring.

- Stranded wire offers better flexibility and is suitable for connections that are subject to movement or vibration.

- Wire gauge indicates the wire’s thickness; a lower gauge number indicates a thicker wire, capable of carrying more current.

Test Leads: Bridging the Gap

Test leads are used to connect your measurement instruments to your circuits. Investing in high-quality test leads is essential for obtaining accurate measurements and ensuring safety.

Look for test leads with:

- Durable insulation to prevent short circuits.

- Secure connections to the multimeter and the circuit.

- Appropriate connectors for your specific instruments and components.

Electronic Components: Stocking Your Inventory

Having a selection of common electronic components on hand will allow you to quickly prototype and experiment with different circuit designs. Essential components to stock include:

- Resistors: Used to limit current flow and provide voltage division. Keep a variety of resistance values on hand.

- Capacitors: Used to store electrical energy and filter signals. Stock a range of capacitance values and voltage ratings.

- Inductors: Used to store energy in a magnetic field and filter signals. Different types and values of inductors are useful for various applications.

Organizing these components in labeled bins or drawers will make it easier to find what you need and prevent them from getting lost or damaged.

Planning and thoughtful design can lay a solid groundwork, but it’s the selection of the right tools that truly brings your electronic test bench to life. Like a painter needs their brushes or a chef their knives, the electronics enthusiast requires a carefully curated collection of equipment to bring their ideas to fruition. This next step involves assembling your arsenal, a set of core measurement instruments, essential hand tools, and a selection of fundamental electronic components. With the right gear at your disposal, you’ll be well-equipped to tackle any project that sparks your interest.

Building the Bench: From Concept to Reality

An electronic test bench is only as good as the tools it houses. Selecting the right equipment can be the difference between a frustrating experience and a productive one.

With your design finalized and your equipment selected, the exciting part begins: constructing the physical manifestation of your vision. This phase transforms your carefully laid plans into a tangible workspace where ideas take shape.

This section provides a detailed guide to building your electronic test bench, from selecting the right materials to optimizing lighting for intricate work.

Workbench Construction: A Solid Foundation

The workbench forms the very bedrock of your electronics endeavors. Its stability, durability, and size will directly impact your comfort and efficiency.

Choosing the right material is the first crucial decision. Common options include wood, metal, and even pre-fabricated workbenches. Each material offers distinct advantages and disadvantages.

Material Choices: Weighing the Options

Wood is a popular choice due to its affordability, ease of workability, and natural aesthetic. Solid wood offers excellent strength and stability, while plywood provides a cost-effective alternative. However, wood is susceptible to moisture damage and may require sealing or painting for added protection.

Metal offers superior strength and durability, making it ideal for heavy-duty applications. Steel is a common choice, providing a robust and stable platform for sensitive equipment. However, metal workbenches can be more expensive and require specialized tools for assembly. Consider grounding requirements when using a metal frame.

Pre-fabricated workbenches offer convenience and ease of assembly. These benches are typically made from a combination of materials, such as metal frames and laminate tops. While offering a quick solution, they may lack the customization options of a DIY build.

Step-by-Step Guide to Building a Sturdy Workbench

-

Planning and Measurements: Before you begin, finalize your workbench dimensions based on your available space and equipment requirements. Create a detailed plan, including all measurements and material lists.

-

Frame Construction: Build the frame using your chosen material. Ensure all joints are strong and secure. For wood frames, use screws and wood glue for maximum stability. For metal frames, welding or bolting are common methods.

-

Work Surface Installation: Attach the work surface to the frame. Use appropriate fasteners to ensure a secure and flush fit. Consider adding a non-slip mat or a static-dissipative surface to protect your components.

-

Reinforcement: Reinforce the workbench frame with additional supports as needed. This is especially important for heavy equipment or if you plan to mount accessories.

-

Finishing: Apply a protective finish to the workbench surface. This will help prevent damage from spills, scratches, and other hazards.

Equipment Mounting and Placement: Strategic Organization

Once your workbench is built, the next step is strategically placing your equipment. Careful consideration of ergonomics and workflow can significantly improve your efficiency and reduce fatigue.

Think of your workbench as a cockpit – everything should be within easy reach and logically arranged.

Instrument Placement: Optimizing Accessibility

Oscilloscope: Position the oscilloscope at eye level and within easy reach. This allows for comfortable viewing of waveforms during analysis.

Multimeter: Keep the multimeter close at hand for quick measurements. Consider a stand or mounting bracket to free up bench space.

Power Supply: Place the power supply within easy reach of your project area. Ensure adequate ventilation to prevent overheating.

Shelving and Storage: Keeping Components Organized

Integrate shelves and drawers into your workbench design to store electronic components, tools, and accessories.

Clear plastic bins with labels can help you quickly locate resistors, capacitors, and other essential parts. Drawers are ideal for storing hand tools, soldering equipment, and other items that you want to keep out of sight.

Consider a pegboard to hang frequently used tools, keeping them readily accessible.

Illumination: Shedding Light on the Details

Proper lighting is crucial for detailed electronics work. Adequate illumination reduces eye strain, improves accuracy, and enhances overall comfort.

Selecting Task Lighting: Brightness and Color Temperature

Choose task lighting that provides sufficient brightness for your specific needs. LED lights are a popular choice due to their energy efficiency, long lifespan, and adjustable brightness.

Consider the color temperature of the lighting. Cool white light (5000-6500K) is ideal for detailed work, as it provides good contrast and clarity. Warm white light (2700-3000K) is more comfortable for general illumination.

Positioning for Optimal Visibility

Position your task lighting to minimize shadows and glare. Adjustable lamps allow you to direct the light precisely where you need it.

Consider using multiple light sources to provide balanced illumination. A combination of overhead lighting and task lighting can create a comfortable and productive workspace.

Avoid placing lights directly in your line of sight, as this can cause glare and eye strain. Experiment with different angles and positions to find the optimal lighting arrangement for your specific needs.

Safety Considerations: Prioritizing Your Well-being

The allure of electronics projects is undeniable. The prospect of creating something tangible, of bending technology to your will, is a powerful motivator. However, this creative pursuit must always be tempered with a deep respect for safety. Working with electricity, even at low voltages, presents inherent risks that demand careful consideration and preventative measures. A commitment to safety isn’t just a recommendation; it’s an absolute requirement for a sustainable and enjoyable electronics hobby or profession.

This section outlines essential safety practices, covering electrostatic discharge (ESD) protection, electrical safety protocols, and safe soldering techniques.

ESD Protection: Guarding Against Static

Electrostatic discharge, or ESD, is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. You’ve likely experienced this as a static shock when touching a doorknob after walking across a carpet. While that small shock is harmless to you, it can be devastating to sensitive electronic components.

Many semiconductors, particularly CMOS and MOSFET devices, are easily damaged by even small amounts of static electricity. Preventing ESD is therefore critical for preserving the lifespan and functionality of your components.

Grounding Techniques: Your First Line of Defense

Grounding is the most effective way to prevent ESD damage. The principle is simple: provide a path for static electricity to safely discharge to the ground, preventing it from building up and damaging components.

- The Grounded Workbench: Your workbench should be grounded using a grounding mat connected to the mains earth ground. This creates a common ground point for all your equipment and components.

- Grounding Cords: All equipment such as oscilloscopes, power supplies, and soldering stations should be connected to properly grounded outlets.

- Wrist Straps: Wear an antistatic wrist strap connected to the grounding mat while handling electronic components. The wrist strap keeps you at the same electrical potential as the grounded surface.

Antistatic Mats and Wrist Straps: Added Assurance

While grounding the workbench is crucial, antistatic mats and wrist straps provide an extra layer of protection.

- Antistatic Mats: These mats are designed to dissipate static charges quickly and safely. They are placed on the workbench to provide a grounded work surface.

- Wrist Straps: An antistatic wrist strap consists of a conductive strap worn around the wrist and connected to the grounding mat with a wire. It ensures that any static charge on your body is safely discharged to the ground. Always ensure the wrist strap makes good contact with your skin for it to be effective.

Electrical Safety: Avoiding Hazards

Working with electricity requires a healthy dose of respect and adherence to safety protocols. Even seemingly low voltages can be dangerous under the wrong circumstances. Understanding basic electrical safety principles is paramount to preventing shocks, burns, and equipment damage.

Proper Wiring and Grounding: Foundation of Safe Circuits

The foundation of electrical safety lies in proper wiring and grounding practices.

- Outlet Integrity: Ensure that all electrical outlets used in your workspace are properly wired and grounded. Use an outlet tester to verify correct wiring.

- Grounding Compliance: Never bypass or defeat grounding connections. The grounding system is designed to protect you from electrical shock by providing a safe path for fault currents.

- Regular Inspections: Regularly inspect power cords and cables for damage. Replace any cords with cracked insulation or exposed wires.

Surge Protection: Shielding Your Equipment

Power surges and voltage spikes can damage sensitive electronic equipment. A surge protector is a device designed to protect electronic devices from voltage spikes.

- Surge Protector Usage: Connect all your electronic equipment to a surge protector.

- Quality Matters: Invest in a high-quality surge protector with sufficient joule rating to handle potential surges.

- Regular Replacement: Surge protectors have a limited lifespan. Replace them periodically, especially after a major electrical event.

Safe Soldering Practices: Minimizing Risks

Soldering is a fundamental skill in electronics, but it involves working with high temperatures and potentially harmful fumes.

Handling Hot Soldering Tools: Respect the Heat

Soldering irons operate at temperatures high enough to cause severe burns.

- Secure Placement: Always place the soldering iron in its stand when not in use. Never leave a hot soldering iron unattended.

- Careful Handling: Use caution when handling the soldering iron. Avoid touching the hot tip or any heated metal parts.

- Protective Gear: Consider wearing heat-resistant gloves or finger guards to protect your hands from accidental burns.

Ventilation: Breathing Easy

Soldering produces fumes that can be harmful if inhaled. These fumes contain rosin, a substance that can cause respiratory irritation and allergic reactions.

- Well-Ventilated Area: Always solder in a well-ventilated area. Open windows and doors to allow fresh air to circulate.

- Fume Extractor: A fume extractor is a device that removes soldering fumes from the air. It is highly recommended for frequent soldering.

- Respiratory Protection: If you are sensitive to soldering fumes, consider wearing a respirator or dust mask to protect your lungs.

Organization and Storage: Maintaining a Tidy Workspace

After meticulously planning your electronic test bench, acquiring the necessary equipment, and carefully constructing the physical structure, it’s easy to overlook a crucial aspect: organization. A cluttered workspace is not only visually unappealing but also significantly hinders efficiency and can even compromise the safety of your projects.

Effective organization and storage are paramount to maximizing productivity and minimizing frustration. This section provides practical tips and strategies for keeping your components, tools, and wiring neatly organized, ensuring that everything you need is readily accessible and your workspace remains a haven for creativity and innovation.

Component Storage: A Place for Everything

The sheer number of components involved in electronics projects, from resistors and capacitors to integrated circuits, can quickly lead to chaos if not managed effectively. The key to successful component storage is a system that allows you to quickly locate the parts you need without having to sift through a jumbled mess.

Bins, drawers, and labels are your allies in this endeavor. Small, clear plastic bins are ideal for storing resistors, capacitors, and other discrete components. Label each bin clearly with the component type and value.

Drawers, especially those with dividers, are perfect for organizing integrated circuits, transistors, and other larger components. Again, labeling is essential. Consider using a label maker for professional-looking and durable labels.

For larger components, such as transformers or heatsinks, consider using larger storage containers or shelves. The goal is to have a designated place for every type of component.

Finally, remember to store your components in a dry, safe place to prevent damage from moisture or physical impact. Anti-static bags can be used for sensitive components.

Tool Organization: Accessibility and Efficiency

Having the right tools readily available is crucial for a smooth and efficient workflow. Fumbling through a drawer or toolbox searching for a specific screwdriver or soldering iron is a waste of valuable time and can be incredibly frustrating. A well-organized tool setup streamlines your work and helps you maintain focus.

Consider creating a system that keeps your most frequently used tools within easy reach. Tool organizers, pegboards, and magnetic strips are excellent options.

Tool organizers with designated slots for each tool are perfect for keeping screwdrivers, pliers, wire strippers, and other hand tools neatly arranged. Pegboards are incredibly versatile and can be customized to hold a wide variety of tools using hooks and hangers.

Magnetic strips are ideal for storing small metal tools, such as tweezers, precision screwdrivers, and soldering aids. Mount the magnetic strip on a wall or the side of your workbench for easy access.

Don’t forget about your soldering iron. A dedicated soldering iron stand is a must-have for safety and convenience. Choose a stand with a sponge for cleaning the soldering tip.

Wiring Management: Taming the Cables

Cables are the bane of many electronic workspaces. They can quickly become tangled, creating a mess that is difficult to navigate and can even pose a safety hazard. Effective wiring management is essential for maintaining a clean and organized workspace.

Start by routing your cables carefully, keeping them as short and direct as possible. Avoid running cables across walkways or areas where they could be easily snagged.

Labeling cables is crucial for identifying them quickly and easily. Use a label maker or write directly on the cable with a permanent marker. Label both ends of each cable with a clear and concise description of its purpose.

Cable ties and organizers are indispensable for keeping wiring neat and tidy. Use cable ties to bundle cables together and prevent them from tangling. Cable organizers, such as cable sleeves or cable channels, can be used to conceal and protect cables.

Consider using different colored cables for different types of connections. This can make it easier to identify and trace cables. For example, you could use red cables for power connections and black cables for ground connections.

By implementing these organization and storage strategies, you can create a workspace that is not only visually appealing but also highly functional and efficient. A well-organized electronic test bench will enhance your productivity, reduce frustration, and allow you to focus on the creative aspects of your projects.

Testing and Calibration: Ensuring Accuracy

Building a meticulously planned and well-equipped electronic test bench is only half the battle. The true value of your test bench lies in the accuracy and reliability of the measurements you obtain. This section focuses on the essential procedures for testing and calibrating your core instruments, ensuring that your power supply, oscilloscope, and multimeter are performing optimally. Accurate measurements are the foundation of sound analysis and successful project outcomes, making these steps indispensable.

Verifying Power Supply Output: Accurate Voltage and Current

Your power supply is the lifeblood of your electronic projects, providing the necessary voltage and current to power your circuits. Before relying on it for critical tasks, it’s essential to verify its output accuracy.

First, visually inspect the power supply for any signs of damage, such as frayed cords, loose connections, or bulging capacitors. Address any issues before proceeding.

Next, use your multimeter to measure the output voltage at various settings. Compare the measured values to the settings on the power supply.

Ideally, the measured voltage should be within a specified tolerance (e.g., ±1% or ±0.1V) of the set voltage. Consult the power supply’s datasheet for its accuracy specifications.

Similarly, verify the current output. Connect a suitable load resistor to the power supply output and measure the current flowing through the circuit using your multimeter. Again, compare the measured current to the expected value based on the power supply’s current limit setting and the load resistance.

If the voltage or current readings are significantly off, consult the power supply’s manual for troubleshooting steps or consider recalibrating the unit if it has that capability. If not, it may be time for a replacement to ensure accurate and reliable power delivery to your circuits.

Calibrating Oscilloscope and Multimeter: Achieving Precision

An oscilloscope and multimeter are your primary tools for analyzing and troubleshooting electronic circuits. Regular calibration is crucial for maintaining the accuracy of their measurements.

Oscilloscope Calibration

Oscilloscope calibration involves adjusting its internal settings to ensure that the displayed waveforms accurately represent the input signals.

Most oscilloscopes have a built-in calibration signal, typically a square wave with a known frequency and amplitude. This signal is used as a reference for adjusting the probe compensation and vertical gain.

- Probe Compensation: Connect a probe to the oscilloscope’s calibration output. Adjust the probe’s compensation capacitor until the displayed square wave has flat tops and bottoms, with no overshoot or undershoot. An improperly compensated probe can distort the displayed waveform, leading to inaccurate measurements.

- Vertical Gain: Apply the calibration signal to a channel on the oscilloscope. Adjust the vertical gain (volts/division) control until the displayed waveform’s amplitude matches the specified value of the calibration signal. This ensures that the oscilloscope accurately measures voltage levels.

- Timebase Calibration: Verify the accuracy of the timebase (seconds/division) by comparing the measured period of the calibration signal to its known frequency. Adjust the timebase control if necessary to ensure accurate time measurements.

It’s important to note that some oscilloscopes require professional calibration by a qualified technician, especially for high-precision measurements. Refer to the oscilloscope’s manual for detailed calibration instructions and recommendations.

Multimeter Calibration

Multimeter calibration ensures that the instrument accurately measures voltage, current, resistance, and other parameters.

Unlike oscilloscopes, most handheld multimeters do not have built-in calibration signals or procedures. Calibration typically involves comparing the multimeter’s readings to those of a calibrated reference meter or a precision voltage/current source.

- Voltage Calibration: Use a precision voltage source to apply known voltages to the multimeter’s input terminals. Compare the multimeter’s readings to the source’s output voltage. Adjust the multimeter’s internal calibration potentiometers, if accessible, to minimize the difference between the measured and reference values.

- Current Calibration: Use a precision current source to supply known currents to the multimeter’s input terminals. Compare the multimeter’s readings to the source’s output current. Adjust the internal calibration potentiometers, if accessible, to minimize the difference between the measured and reference values.

- Resistance Calibration: Use precision resistors with known values. Compare the multimeter’s resistance readings to the resistor’s nominal values. Adjust the internal calibration potentiometers, if accessible, to minimize the difference between the measured and reference values.

If your multimeter requires calibration beyond the capabilities of basic adjustments, it’s best to send it to a certified calibration laboratory. These labs have specialized equipment and trained technicians to ensure that your multimeter meets its accuracy specifications.

Regular testing and calibration are vital for maintaining the accuracy and reliability of your electronic test bench instruments. By following these guidelines, you can ensure that your measurements are trustworthy and that your projects are built on a solid foundation of precision.

DIY Electronic Test Bench FAQs

This section addresses common questions about building your own electronic test bench. We aim to provide clarity and helpful information for your project.

What’s the most important thing to consider when designing an electronic test bench?

Ergonomics and organization. Ensure the workbench height is comfortable for prolonged use. Optimize the layout for easy access to tools, components, and power outlets. Good organization reduces clutter and improves efficiency.

What are some essential tools for an electronic test bench?

A multimeter is fundamental for voltage, current, and resistance measurements. A variable power supply is crucial for powering circuits under test. An oscilloscope helps visualize waveforms and analyze circuit behavior. Consider adding a signal generator for injecting test signals.

How much should I budget for building an electronic test bench?

The cost varies greatly depending on your needs and existing resources. A basic bench can be built for under $200 using repurposed materials. A fully equipped electronic test bench with new tools and a custom frame could cost significantly more.

Where can I find inspiration for my own electronic test bench design?

Online communities and forums dedicated to electronics and DIY projects are excellent resources. Search for "DIY workbench" or "electronics lab setup" on platforms like Reddit, YouTube, and Instructables. Many builders share their designs and experiences.

So, get out there and start building your own awesome electronic test bench! I’m confident you’ll see a huge difference in your projects. Have fun, and let me know what cool things you come up with!