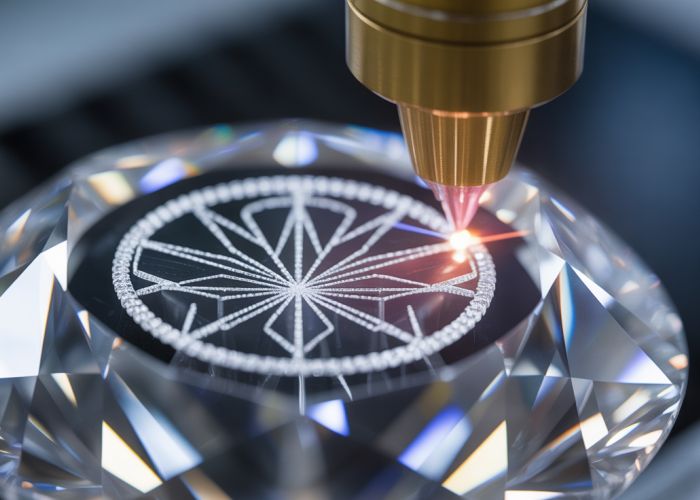

The industrial applications of Femtosecond Lasers are expanding, and diamond laser cutting exemplifies this trend. De Beers Group, a prominent figure in the diamond industry, recognizes the potential of this technology. Material Ablation, a key mechanism in the process, achieves highly precise cuts. Advanced systems located in Antwerp, Belgium now utilize these techniques to improve efficiency.

Diamond Laser Cutting: Structuring an Informative Article

To create a comprehensive and effective article on "Diamond Laser Cutting: The Future of Precision!", a well-structured layout is crucial. This layout should prioritize clarity, readability, and a logical flow of information, focusing heavily on explaining the core technology and its implications.

Introduction: Setting the Stage

The introduction needs to grab the reader’s attention and clearly define the article’s scope.

- Hook: Begin with a compelling statement or question about the traditional methods of diamond cutting and their limitations. For example, highlight the imperfections and material waste associated with older techniques.

- Definition: Introduce "diamond laser cutting" as a more precise and efficient alternative. Clearly state that the article will explore its principles, advantages, and potential applications.

- Thesis Statement: Summarize the main point of the article. For example, "Diamond laser cutting is poised to revolutionize various industries by offering unparalleled precision, reduced material waste, and the ability to create intricate designs previously unattainable."

Understanding Diamond Laser Cutting Technology

This section provides the technical foundation for understanding the process.

The Fundamentals of Laser Cutting

Explain the basic principles of laser cutting.

- What is a Laser? Define a laser as a highly focused beam of light that generates intense heat. Mention key properties like coherence and monochromaticity without delving into overly technical details.

- How it Works: Describe how the laser beam interacts with the diamond. Explain that the focused energy vaporizes or ablates the material.

- Types of Lasers Used: Discuss the different types of lasers suitable for diamond cutting, such as femtosecond lasers or UV lasers. Highlight the advantages of each type for this specific application.

The Diamond-Laser Interaction

This subsection explores the specific challenges and considerations when using lasers on diamonds.

- Material Properties: Briefly explain the unique hardness and thermal conductivity of diamonds, and how these properties impact the laser cutting process.

- Heat Management: Discuss the importance of managing heat buildup during laser cutting to prevent thermal damage or cracking. Explain techniques like using pulsed lasers or cooling systems.

- Precision Control: Emphasize the crucial role of precise laser control and sophisticated software for achieving intricate cuts and minimizing material loss.

Advantages of Diamond Laser Cutting

This section outlines the key benefits of using diamond laser cutting compared to traditional methods.

- Enhanced Precision: Provide specific examples of the level of precision achievable with laser cutting. For example, "Achieving cuts down to microns in size."

- Reduced Material Waste: Quantify the reduction in material waste compared to traditional sawing or cleaving. For instance, "Laser cutting can reduce material waste by up to 30%."

- Intricate Designs: Highlight the ability to create complex geometries and intricate designs that are impossible to achieve with conventional methods.

- Non-Contact Process: Explain that laser cutting is a non-contact process, minimizing the risk of mechanical stress or damage to the diamond.

- Automation and Speed: Discuss the potential for automating the laser cutting process, leading to increased production speed and reduced labor costs.

Comparison Table: Laser Cutting vs. Traditional Methods

| Feature | Diamond Laser Cutting | Traditional Methods (Sawing, Cleaving) |

|---|---|---|

| Precision | Very High | Moderate |

| Material Waste | Low | High |

| Design Complexity | High | Low |

| Process | Non-Contact | Contact |

| Automation | High | Low |

Applications of Diamond Laser Cutting

Explore the various industries and applications that benefit from diamond laser cutting.

- Jewelry Industry: Focus on the ability to create intricate cuts, customized designs, and unique diamond shapes for jewelry.

- Industrial Applications: Discuss the use of laser-cut diamonds in tools, cutting instruments, and wear-resistant coatings.

- Scientific Research: Highlight the use of diamond laser cutting in creating microfluidic devices, optical components, and other specialized research tools.

- Medical Applications: Explore the potential for using laser-cut diamonds in surgical instruments or drug delivery systems.

Challenges and Future Trends

Address the limitations and future developments in diamond laser cutting technology.

- Initial Investment: Acknowledge the higher upfront cost of laser cutting equipment compared to traditional methods.

- Expertise Required: Explain that operating and maintaining laser cutting systems requires specialized training and expertise.

- Laser Technology Advancements: Discuss ongoing research and development in laser technology that could further improve the efficiency and precision of diamond laser cutting.

- Automation and AI Integration: Highlight the potential for integrating artificial intelligence and advanced automation systems to optimize the laser cutting process.

- Expanding Applications: Speculate on potential new applications for diamond laser cutting in emerging fields like nanotechnology and quantum computing.

Diamond Laser Cutting: Frequently Asked Questions

Diamond laser cutting is a revolutionary technology, and it’s natural to have questions. Here are some common ones.

What materials can diamond laser cutting be used on?

While the name focuses on diamonds, diamond laser cutting can be used on a variety of ultra-hard materials. These include cubic boron nitride (CBN), ceramics, and other advanced materials that are difficult to machine with traditional methods. It offers precise cuts on materials that would otherwise be prone to damage.

How does diamond laser cutting achieve such high precision?

Diamond laser cutting relies on focused laser beams. These beams are extremely precise and generate minimal heat compared to traditional methods. This allows for very accurate cuts with narrow kerf widths, resulting in minimal material waste and highly detailed designs.

Is diamond laser cutting suitable for mass production?

Yes, diamond laser cutting is suitable for mass production. Once a program is set, the process is highly repeatable. Automation can further increase throughput, making it ideal for applications where large quantities of parts are required with consistently high precision.

What are the advantages of diamond laser cutting over traditional methods?

Diamond laser cutting offers numerous advantages. It is more precise, creates less waste, and can cut intricate shapes. Furthermore, it reduces the risk of damage to the material being cut. These factors combined make it a superior option for many advanced manufacturing applications.

So there you have it – a glimpse into how diamond laser cutting is shaping the future. We hope you found it insightful. Ready to explore how this tech can benefit your project? Let’s get in touch!