The efficiency of an air conditioning system significantly depends on the reliable operation of its compressor related component. Proper maintenance, a crucial service offered by HVAC professionals, directly affects the lifespan of each compressor related component. Early detection of issues is vital, which requires specialized tools such as pressure gauges to accurately assess system performance. Understanding the function of each compressor related component helps prevent system failures which can lead to costly repairs or replacements from companies like Carrier.

Crafting the Ideal Article Layout: Compressor Component Failing? 5 Fixes You Need To Know!

When developing an article around the topic "Compressor Component Failing? 5 Fixes You Need To Know!" with the keyword focus on "compressor related component," a strategic layout is crucial for engagement and comprehension. This breakdown outlines the optimal structure to achieve an informative and actionable piece.

1. Compelling Introduction: Hook, Problem, Promise

The introduction is paramount. It needs to immediately grab the reader’s attention, establish the problem, and promise a solution.

- Hook: Start with a relatable scenario. For example, "Is your compressor sputtering and losing power? A failing compressor related component could be the culprit."

- Problem: Briefly explain the consequences of ignoring a failing component. This could include reduced efficiency, increased energy costs, or even complete compressor failure.

- Promise: Clearly state that the article will provide actionable fixes. "This article outlines 5 key fixes to address common problems with compressor related components, getting your compressor back in top shape."

2. Understanding Compressor Components & Failure

Before diving into fixes, establish a basic understanding of common compressor related components and the common failure points.

2.1 Key Compressor Components

This section lists and briefly describes important compressor components. A table format can be very effective here.

| Component Name | Function | Common Failure Symptoms |

|---|---|---|

| Air Filter | Prevents dust and debris from entering the compressor. | Reduced airflow, dirty filter appearance. |

| Check Valve | Prevents backflow of air. | Air leaking from the compressor, reduced pressure. |

| Pressure Switch | Controls the compressor’s on/off cycles based on pressure. | Compressor constantly running, compressor not turning on. |

| Motor | Powers the compressor pump. | Humming sound, no start, tripping breaker. |

| Belt (If Applicable) | Transfers power from the motor to the pump. | Squealing noise, visible wear and tear. |

2.2 Common Causes of Component Failure

Explain why these compressor related components might fail. This section provides context for the fixes that will follow.

- Lack of Maintenance: Neglecting regular maintenance (e.g., changing air filters) is a primary cause.

- Overuse: Running the compressor beyond its duty cycle can stress components.

- Contamination: Dirt, moisture, and other contaminants can damage internal parts.

- Wear and Tear: All components eventually wear out with use.

- Improper Installation: Incorrect installation can lead to premature failure.

3. 5 Fixes for Failing Compressor Components

This is the core of the article, where you deliver on the promised solutions. Each fix should be presented in a structured and easy-to-follow manner.

For each fix:

- Clear Heading: Use descriptive headings like "Fix #1: Replacing a Clogged Air Filter".

- Problem Addressed: Briefly restate the problem that this fix resolves.

- Tools & Materials: List all necessary tools and materials in a bulleted list. This adds a practical element.

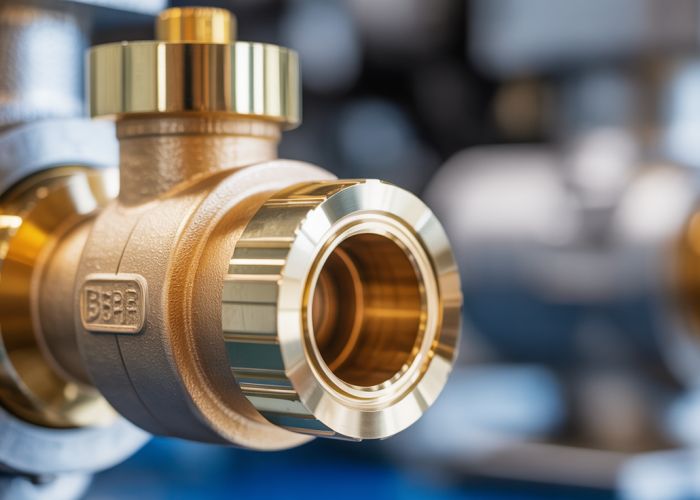

- Step-by-Step Instructions: Provide clear, concise, and numbered instructions. Consider including images or illustrations to visually guide the reader.

- Important Considerations: Highlight any safety precautions, potential challenges, or alternative approaches.

Here’s a sample fix structure:

3.1 Fix #1: Replacing a Clogged Air Filter

- Problem Addressed: Reduced airflow, decreased compressor efficiency, potential damage to internal components.

- Tools & Materials:

- New air filter (correct size for your compressor model)

- Screwdriver or wrench (depending on filter housing)

- Clean cloth

- Step-by-Step Instructions:

- Turn off and unplug the compressor.

- Locate the air filter housing.

- Remove the filter housing cover.

- Remove the old air filter.

- Clean the filter housing with a clean cloth.

- Insert the new air filter.

- Replace the filter housing cover.

- Important Considerations:

- Refer to your compressor’s manual for the correct air filter type and replacement frequency.

- Inspect the air filter housing for damage and replace if necessary.

Follow this structure for each of the 5 fixes. Examples might include:

- Fix #2: Draining Moisture from the Tank

- Fix #3: Inspecting and Replacing the Check Valve

- Fix #4: Checking and Tightening Belt Tension (If Applicable)

- Fix #5: Troubleshooting the Pressure Switch

4. Preventative Maintenance Tips

Offer actionable advice on preventing future compressor related component failures. This reinforces your expertise and provides added value.

- Regular Inspections: Encourage regular visual inspections for leaks, damage, and unusual noises.

- Proper Lubrication: If the compressor requires lubrication, specify the correct type and schedule.

- Cleanliness: Maintain a clean work environment to minimize contamination.

- Duty Cycle Awareness: Avoid overworking the compressor beyond its recommended duty cycle.

- Professional Servicing: Recommend periodic professional servicing for a thorough inspection and maintenance.

This structure ensures the article is not only informative but also practical and user-friendly, directly addressing the reader’s need to troubleshoot and fix a failing compressor related component.

FAQs: Compressor Component Failing? 5 Fixes You Need To Know!

Here are some frequently asked questions about diagnosing and fixing a failing compressor component to help you understand the process better.

How can I tell if the problem is definitely a compressor related component and not something else in the system?

Listen closely! A failing compressor related component often makes unusual noises like rattling, grinding, or hissing. Also, check the refrigerant levels and electrical connections. If those are okay, and the compressor still isn’t working or is making strange sounds, the compressor itself is likely the issue.

What happens if I keep running the system with a failing compressor component?

Continuing to run your system with a damaged compressor related component will likely lead to further damage to the compressor itself, and potentially other parts of the system. This can result in more expensive repairs down the line.

Are there any temporary fixes I can try while waiting for a professional repair of a compressor related component?

Unfortunately, there aren’t really any reliable temporary fixes for a failing compressor related component. It’s best to turn off the system to prevent further damage and call a qualified technician as soon as possible. Attempting DIY fixes could be dangerous and could worsen the situation.

How much does it usually cost to repair or replace a compressor related component?

The cost varies significantly depending on the specific component that’s failing, the type of system you have, and the labor rates in your area. Get quotes from multiple HVAC professionals to ensure you’re getting a fair price.

So, there you have it! Hopefully, you’ve got a better handle on keeping your compressor related component in tip-top shape. Remember, a little maintenance can go a long way! Thanks for reading, and good luck out there!