The functionality of a ballast tank submarine relies heavily on understanding Archimedes’ principle, which dictates buoyancy. Specifically, ballast tanks, integral components of a ballast tank submarine, control its submersion and surfacing by altering its displacement. Naval architects, often associated with institutions like the U.S. Naval Academy, play a crucial role in designing and optimizing these complex systems. Hydrostatic pressure, a significant environmental factor, influences the operation of a ballast tank submarine, requiring sophisticated engineering solutions. Ultimately, the interplay of these elements ensures the safe and effective navigation of a ballast tank submarine beneath the waves.

Unveiling the Secrets of Ballast Tank Submarines

Submarines, those enigmatic vessels of the deep, have long captured the human imagination. From their initial, somewhat clumsy, iterations to the sophisticated, technologically advanced machines that patrol the oceans today, submarines have played a pivotal role in naval history and power projection. Their ability to operate covertly beneath the waves provides a unique strategic advantage, making them indispensable assets for maritime nations.

At the heart of a submarine’s ability to dive and resurface lies a deceptively simple, yet remarkably effective, system: the ballast tank.

Ballast tanks are not merely compartments; they are the lungs of the submarine, allowing it to control its buoyancy and navigate the underwater realm. Without them, a submarine would be little more than an expensive, immobile underwater observation post.

A Brief History of Submersibles

The concept of underwater navigation dates back centuries, with early experiments involving rudimentary submersibles powered by oars or manual cranks. However, it was the development of effective ballast systems that truly unlocked the potential of these vessels.

Early submarines faced significant challenges in controlling their depth and maintaining stability. These early designs often relied on crude methods for flooding and emptying ballast tanks, making them difficult and dangerous to operate.

The advent of steam power and, later, diesel-electric propulsion, coupled with advancements in ballast tank design, revolutionized submarine technology. Submarines transitioned from experimental curiosities to formidable weapons platforms.

The Indispensable Ballast Tank

The primary function of ballast tanks is to control a submarine’s buoyancy. By selectively flooding these tanks with seawater, a submarine increases its overall density, causing it to submerge. Conversely, expelling water from the tanks with compressed air decreases the submarine’s density, allowing it to surface.

This seemingly straightforward process involves complex engineering and precise control systems. The design, placement, and operation of ballast tanks are critical to a submarine’s stability, maneuverability, and overall operational effectiveness.

Article Scope: Exploring the Depths of Ballast Tank Technology

This article aims to provide a comprehensive exploration of ballast tank submarines. We will delve into the fundamental principles governing their operation, examine the design and engineering considerations that shape their construction, and analyze the operational realities that influence their performance.

From the basic physics of buoyancy to the intricacies of depth control and the challenges of operating in diverse marine environments, this exploration will illuminate the crucial role of ballast tanks in enabling submarines to conquer the underwater world. The journey will cover the scientific underpinnings, the engineering marvels, and the operational protocols that define this fascinating area of naval technology.

At the heart of a submarine’s design lies a mastery of fundamental physics. Understanding how these vessels navigate the depths requires grasping the interplay between buoyancy, Archimedes’ Principle, and density. These concepts, often taught in introductory physics, are not mere academic exercises, but the very bedrock upon which submarine technology is built.

The Science of Submersion: Buoyancy, Archimedes’ Principle, and Density

The ability of a submarine to effortlessly transition between floating on the surface and navigating the ocean depths is a testament to the ingenious application of basic scientific principles. Let’s delve into the key concepts that govern a submarine’s ability to dive and resurface.

Understanding Buoyancy

Buoyancy is the upward force exerted by a fluid that opposes the weight of an immersed object. This force is what allows ships to float and is also crucial for submarines. Without buoyancy, any object placed in water would simply sink.

The magnitude of the buoyant force is determined by the weight of the fluid displaced by the object, which leads us to Archimedes’ Principle.

Archimedes’ Principle Explained

Archimedes’ Principle is a cornerstone of naval architecture and submarine design. It states that the buoyant force acting on an object submerged in a fluid is equal to the weight of the fluid that the object displaces.

In simpler terms, a submarine experiences an upward force equal to the weight of the water it pushes aside. If this upward force is greater than the submarine’s weight, the submarine floats.

Conversely, if the submarine weighs more than the water it displaces, it sinks. Submarines manipulate their weight to control whether they rise, sink, or remain at a constant depth.

The Role of Density in Submarine Operation

Density, defined as mass per unit volume, plays a vital role in determining whether an object floats or sinks. An object will float if its average density is less than the density of the fluid it is placed in.

Conversely, it will sink if its average density is greater than the fluid’s density.

A submarine, however, doesn’t simply rely on its inherent density to control its buoyancy. Instead, it actively adjusts its density by controlling the amount of water in its ballast tanks.

By flooding these tanks with seawater, the submarine increases its overall weight and, therefore, its average density, causing it to submerge.

To surface, the submarine expels water from the ballast tanks, decreasing its overall weight and density, allowing it to rise.

The delicate balance between weight, displacement, and density is what allows submarines to achieve controlled submersion, maintain neutral buoyancy at specific depths, and resurface at will. This interplay of physics is not only fascinating but also essential to understanding the operational capabilities of these remarkable underwater vessels.

Archimedes’ Principle dictates the physics, but the ballast tank is where the theory meets practical engineering. These tanks are the key to a submarine’s ability to control its buoyancy, allowing it to slip beneath the waves and then re-emerge at will.

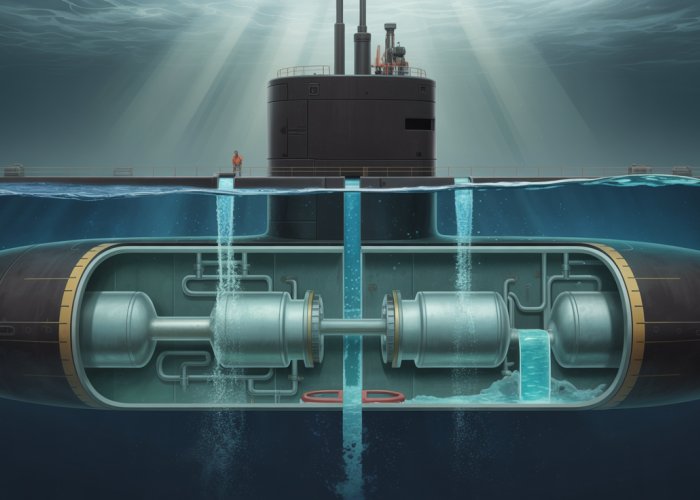

Ballast Tanks: The Heart of Submarine Diving and Surfacing

The ballast tank system is the lynchpin of a submarine’s ability to submerge and surface. It is through the meticulous design, functionality, and operation of these tanks that a submarine can alter its density relative to the surrounding water, thereby controlling its vertical movement.

What Are Ballast Tanks? Definition and Purpose

Ballast tanks are specialized compartments within a submarine specifically designed to hold water. They are not intended for personnel or equipment but solely for managing the vessel’s buoyancy.

The primary purpose of these tanks is to allow the submarine to precisely control its weight and, therefore, its density. By flooding the tanks with seawater, the submarine increases its overall weight, making it denser than the surrounding water and causing it to submerge. Conversely, by expelling the water, the submarine becomes lighter, less dense, and rises to the surface.

Location and Types of Ballast Tanks

The location and configuration of ballast tanks vary depending on the submarine’s design. However, they are typically situated between the inner pressure hull (which houses the crew and sensitive equipment) and the outer hull. This placement provides structural support and allows for efficient flooding and venting.

Several types of ballast tanks exist, each serving a specific purpose:

-

Main Ballast Tanks: These are the largest tanks and are used for the primary submerging and surfacing operations. They are typically located along the sides of the submarine.

-

Trim Tanks: These smaller tanks are located near the bow and stern of the submarine. They are used to fine-tune the submarine’s trim or angle, ensuring it remains level while submerged.

-

Safety Tanks: These tanks are designed for emergency surfacing. They can be rapidly emptied using high-pressure air to quickly increase buoyancy in critical situations.

-

Hard Tanks vs. Soft Tanks: Ballast tanks are also categorized as "hard" or "soft". Hard tanks are designed to withstand significant external pressure when flooded, while soft tanks are open to the sea at the bottom, allowing water to flow in and out freely as the submarine dives or surfaces.

The Process of Diving: Flooding Ballast Tanks

The process of diving involves carefully flooding the main ballast tanks with seawater. This is achieved by opening sea valves located on the bottom of the tanks, allowing water to rush in and displace the air within.

As the tanks fill, the submarine’s weight increases, and its overall density becomes greater than that of the surrounding water. This negative buoyancy causes the submarine to descend. The rate of descent is controlled by adjusting the amount of water in the ballast tanks and by using the submarine’s hydroplanes (underwater rudders).

The Process of Surfacing: Expelling Water and Venting

Surfacing requires reversing the process of diving. To rise, the submarine must decrease its weight and reduce its density. This is accomplished by expelling the seawater from the ballast tanks.

-

Using Compressed Air: Compressed air, stored in high-pressure reservoirs within the submarine, is forced into the ballast tanks. This air pressure displaces the water, pushing it out through the sea valves.

-

Venting the Tanks: As the water is expelled, the displaced air needs a way to escape. Vents located at the top of the ballast tanks are opened to allow the air to vent to the atmosphere.

By removing the water from the ballast tanks, the submarine reduces its weight and increases its buoyancy, causing it to ascend.

Achieving Neutral Buoyancy: Balancing Weight and Displacement

Neutral buoyancy is the state where a submarine’s weight is exactly equal to the weight of the water it displaces. In this state, the submarine neither rises nor sinks but remains at a constant depth.

Achieving and maintaining neutral buoyancy is crucial for efficient and stable underwater operation. It allows the submarine to move with minimal energy expenditure and maintain a desired depth without constant adjustments.

The crew achieves neutral buoyancy by carefully balancing the amount of water in the trim tanks and making small adjustments to the ballast tanks. Sonar and depth gauges provide real-time feedback, allowing the crew to fine-tune the submarine’s buoyancy and maintain its equilibrium in the water.

Archimedes’ Principle dictates the physics, but the ballast tank is where the theory meets practical engineering. These tanks are the key to a submarine’s ability to control its buoyancy, allowing it to slip beneath the waves and then re-emerge at will.

However, simply submerging isn’t enough. A submarine must also maintain its equilibrium, controlling its depth and attitude with precision. This intricate dance between buoyancy, gravity, and hydrodynamic forces demands a sophisticated understanding of trim, depth control mechanisms, and the structural integrity of the pressure hull.

Maintaining Equilibrium: Depth Control, Trim, and the Pressure Hull

The ability to submerge is only the first step. True mastery of underwater navigation lies in maintaining equilibrium – a delicate balance achieved through precise depth control, careful adjustment of trim, and a pressure hull that can withstand the crushing depths.

The Art of Trim: Achieving Level Navigation

Trim refers to the submarine’s attitude or orientation in the water. An ideally trimmed submarine maintains a level horizontal attitude, neither pitching bow-up nor bow-down.

Achieving proper trim is crucial for efficient and stable underwater navigation. An improperly trimmed submarine will require constant adjustments from its control surfaces, increasing drag and reducing speed and maneuverability.

Adjusting Weight Distribution

Trim is primarily adjusted by carefully shifting the weight distribution within the submarine. This is accomplished using dedicated trim tanks, smaller ballast tanks located fore and aft.

By transferring water between these trim tanks, the crew can subtly alter the submarine’s center of gravity, correcting any imbalances and achieving the desired level attitude.

The Role of Auxiliary Systems

Auxiliary systems, such as pumps and valves, play a critical role in the precise movement of water between trim tanks. These systems are designed for both speed and accuracy, allowing the crew to make real-time adjustments in response to changing conditions.

Depth Control: Mastering Vertical Movement

While trim ensures level navigation, depth control allows the submarine to maintain its desired position in the water column. This requires a combination of ballast tank management and the use of hydrodynamic control surfaces.

Ballast Tanks and Buoyancy Adjustments

Fine-tuning of buoyancy is achieved by making slight adjustments to the amount of water in the ballast tanks. This is a continuous process, as factors such as changes in water density and the submarine’s speed can affect its buoyancy.

Hydroplanes: The Wings of the Deep

Hydroplanes, also known as diving planes, are wing-like control surfaces located on the submarine’s hull. By adjusting the angle of these planes, the crew can generate hydrodynamic forces that push the submarine up or down in the water.

The forward hydroplanes, located near the bow, are particularly important for depth control. They work in conjunction with the stern planes to provide precise control over the submarine’s vertical movement.

Automated Depth Control Systems

Modern submarines are equipped with sophisticated automated depth control systems. These systems use sensors to monitor the submarine’s depth and automatically adjust the hydroplanes to maintain the desired level. The integration of computer technology and advanced sensors has significantly improved the precision and efficiency of depth control.

The Pressure Hull: A Fortress Against the Deep

The pressure hull is the structural shell that encloses the crew compartments and critical equipment. It is designed to withstand the immense pressure exerted by the surrounding water at depth.

Without a robust pressure hull, the submarine would be crushed by the forces of the deep.

Material Science and Engineering

The pressure hull is typically constructed of high-strength steel alloys, carefully selected for their ability to withstand compressive forces. The design and construction of the pressure hull are subject to rigorous engineering standards and quality control procedures.

The Limits of Depth

The maximum operating depth of a submarine is ultimately limited by the strength of its pressure hull. Deeper diving submarines require more robust hulls, adding weight and cost.

Operational Realities: Environmental Factors and Design Considerations

The design and operation of ballast tank systems are not purely theoretical exercises. Real-world environmental conditions and practical engineering constraints significantly influence their effectiveness. Understanding these factors is crucial for optimizing submarine performance and ensuring operational safety.

The Influence of Seawater Conditions

Seawater is far from a uniform substance. Its properties, particularly temperature and salinity, vary considerably depending on geographic location, depth, and season. These variations directly impact the density of the water, which, in turn, affects a submarine’s buoyancy and the performance of its ballast tanks.

Temperature Effects

Cold seawater is denser than warm seawater. This means a submarine operating in colder waters will experience greater buoyancy compared to operating in warmer waters at the same depth and with the same ballast configuration.

Naval architects must account for these temperature-induced density changes when designing ballast tank systems. Submarines may need to adjust their ballast load depending on the water temperature to maintain neutral buoyancy.

Salinity Variations

Salinity, the concentration of dissolved salts in seawater, also affects density. Higher salinity increases seawater density. Submarines operating in estuaries or areas with significant freshwater runoff will encounter lower salinity levels, reducing the water’s density and affecting buoyancy.

Salinity gradients can also create challenges for depth control. A submarine crossing a region with a sudden change in salinity may experience unexpected changes in buoyancy, requiring immediate adjustments to the ballast system.

Optimizing Ballast Tank Design

Submarine design must address these environmental variables to ensure optimal performance across a range of operating conditions. Several design considerations are critical:

Tank Size and Configuration

The size and configuration of ballast tanks are carefully calculated to provide sufficient buoyancy control for various operating scenarios. The volume of the tanks must be adequate to compensate for the submarine’s weight and the density of the surrounding water.

Tank placement is equally important. Distributing ballast tanks strategically throughout the hull allows for precise trim adjustments and enhances stability.

Material Selection and Corrosion Resistance

Ballast tanks are constantly exposed to seawater, making them vulnerable to corrosion. Selecting corrosion-resistant materials is paramount for ensuring the long-term integrity of the tanks and the submarine as a whole.

Common materials include specialized steel alloys and protective coatings designed to withstand the harsh marine environment. Regular inspections and maintenance are also essential for detecting and addressing any signs of corrosion before they compromise the system’s functionality.

Venting and Flooding Systems

The efficiency of the venting and flooding systems directly impacts the speed and effectiveness of submersion and surfacing operations. These systems must be designed to handle large volumes of water quickly and reliably.

Furthermore, the design must prevent the ingress of debris or marine organisms that could clog the system and impair its performance. Regular cleaning and maintenance are crucial for maintaining the optimal operation of these vital systems.

By carefully considering these environmental and design factors, engineers can create ballast tank systems that enable submarines to operate safely and effectively in diverse underwater environments.

Looking Ahead: Innovations and the Future of Ballast Tank Technology

The enduring success of the submarine as a critical naval asset is inextricably linked to the ingenuity and constant refinement of its ballast systems. These systems, while seemingly simple in concept, are the key to controlled submersion and resurfacing, granting the submarine its unique operational capabilities.

As we look to the future, several trends are emerging that promise to further enhance the performance, efficiency, and adaptability of ballast tank technology.

The Unwavering Importance of Ballast Tanks

Before delving into future innovations, it’s essential to reiterate the fundamental role of ballast tanks. They are not merely auxiliary components; they are integral to the very essence of submarine operation.

By carefully managing the intake and expulsion of seawater, ballast tanks allow a submarine to precisely control its buoyancy, enabling it to dive, maintain depth, and surface with accuracy and reliability.

Without this capability, the submarine would be rendered a surface vessel, losing its stealth and underwater maneuverability – its core advantages.

Automation and Enhanced Control Systems

One of the most promising areas of development lies in the automation of ballast tank operations.

Modern submarines already incorporate sophisticated control systems, but future iterations are likely to feature even greater levels of automation, leveraging advanced sensors, artificial intelligence, and machine learning algorithms.

These systems will be capable of real-time optimization of ballast distribution, taking into account a multitude of factors such as water density, depth, speed, and sea state.

This increased automation promises to not only reduce the workload on human operators, but also to improve the speed and precision of depth control, particularly in dynamic and challenging environments.

Material Science Advancements

The materials used in ballast tank construction are critical to their long-term reliability and resistance to corrosion. Traditional materials are constantly being re-evaluated and improved.

New alloys, composites, and coatings are being developed to enhance strength, reduce weight, and extend the lifespan of ballast tanks in harsh marine environments.

The use of advanced corrosion-resistant materials is crucial, especially as submarines operate in increasingly diverse and potentially corrosive ocean environments.

Nanomaterials and self-healing polymers are also being explored as potential game-changers, offering the possibility of self-repairing ballast tanks that can withstand minor damage without compromising structural integrity.

Alternative Ballast Systems and Concepts

While traditional ballast tanks are likely to remain a mainstay of submarine design for the foreseeable future, research is underway exploring alternative ballast systems and concepts.

One promising avenue is the development of variable displacement systems, which utilize internal mechanisms to alter the volume of the submarine without the need to flood or expel seawater.

These systems could offer advantages in terms of speed, efficiency, and reduced noise signature.

Another area of interest is the exploration of buoyancy control using shape-changing materials. These materials, which can alter their density or volume in response to external stimuli, could potentially be integrated into the hull of the submarine, allowing for seamless and highly precise buoyancy adjustments.

Adapting to Increased Operating Depths and Demanding Missions

The future of submarine warfare is likely to involve operations at greater depths and in more complex environments.

As submarines venture into deeper waters, the demands on their ballast systems will increase significantly. The pressure hull and associated systems, including ballast tanks, must be designed to withstand immense pressures while maintaining operational efficiency.

Furthermore, future mission profiles may require submarines to operate for extended periods without surfacing, necessitating advanced ballast water management systems to prevent the build-up of biofouling and maintain water quality.

The development of closed-loop ballast systems, which recycle and purify ballast water, could be crucial for enabling these extended submerged operations.

Efficiency and Environmental Considerations

In an era of growing environmental awareness, the efficiency and environmental impact of ballast tank operations are also coming under increasing scrutiny.

Efforts are underway to minimize the discharge of invasive species and pollutants from ballast water, through the development of advanced filtration, sterilization, and treatment technologies.

Furthermore, there is a growing emphasis on reducing the energy consumption associated with ballast tank operations, through the use of more efficient pumps, valves, and control systems.

The integration of renewable energy sources, such as solar or wave power, could also help to reduce the carbon footprint of submarine operations.

In conclusion, the future of ballast tank technology is one of continuous innovation and refinement. By embracing new materials, automation, and alternative concepts, we can ensure that submarines remain a vital and effective component of naval power for generations to come.

Ballast Tank Submarines FAQs

Here are some frequently asked questions about ballast tank submarines and how they function.

How do ballast tanks allow a submarine to dive?

Ballast tanks are compartments within a submarine that can be flooded with seawater. When these tanks fill with water, it increases the submarine’s overall density. This increased density makes the submarine heavier than the water it displaces, causing it to submerge.

What happens to the air when ballast tanks are flooded?

As a ballast tank submarine dives, air in the ballast tanks is vented to the surface or compressed into onboard storage tanks. This venting process is crucial for replacing the air volume with water, which increases the submarine’s weight and allows it to descend.

How does a ballast tank submarine resurface?

To resurface, a ballast tank submarine uses compressed air to force water out of the ballast tanks. This reduces the submarine’s overall density, making it lighter than the water it displaces. The resulting buoyancy allows the submarine to ascend.

Are ballast tanks the only way a submarine controls its depth?

While ballast tanks are essential for initial diving and surfacing, a ballast tank submarine also uses hydroplanes (underwater wings) to fine-tune its depth and maintain a specific level. These hydroplanes help control pitch and depth while submerged and underway.

Hopefully, you’ve got a solid grasp on the fascinating world of the ballast tank submarine now! Whether you’re a seasoned engineer or just curious, we hope this article sparked your interest. Happy diving… virtually speaking, of course!