Accurate project cost estimation relies heavily on understanding the asphalt tonnage formula, a critical calculation for paving projects. Asphalt density, typically measured in pounds per cubic foot, significantly impacts the total tonnage needed for a job. The National Asphalt Pavement Association (NAPA) provides industry guidelines and resources to help contractors refine their estimation methods, including the application of the asphalt tonnage formula. Project managers often use specialized construction estimation software to automate these calculations, improving accuracy and efficiency. These tools help in ensuring projects avoid material waste and stay within budget, both crucial goals for organizations operating in this competitive space. Ultimately, mastering the asphalt tonnage formula is paramount for civil engineers aiming to optimize material usage and ensure project profitability.

Decoding the Asphalt Tonnage Formula: Achieving Accurate Project Estimates

Accurately estimating the required asphalt tonnage is crucial for any paving project, from driveways to highways. Underestimating can lead to delays and cost overruns, while overestimating results in wasted materials and unnecessary expenses. Understanding and correctly applying the asphalt tonnage formula is therefore paramount. This guide provides a comprehensive breakdown of the formula and its components.

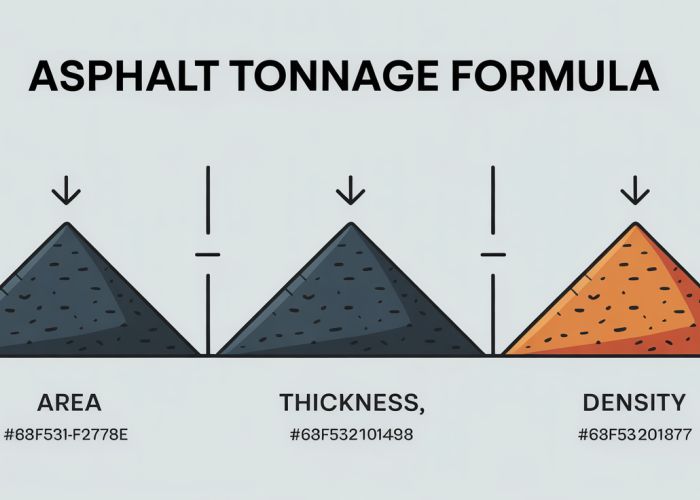

Understanding the Basic Asphalt Tonnage Formula

The core formula for calculating asphalt tonnage is relatively straightforward:

Asphalt Tonnage = (Area x Thickness x Density) / 2000

Let’s dissect each component to ensure clarity.

Area: Measuring the Project’s Surface

The Area refers to the total surface area to be paved, measured in square feet. Accurate measurement is critical.

- For rectangular areas: Area = Length x Width

- For irregular shapes: Divide the area into simpler geometric shapes, calculate the area of each, and sum the results. Construction plans often provide area calculations, but always verify them.

- Accounting for Curves: When working with curved driveways or pathways, use appropriate geometric formulas (e.g., sector of a circle) or employ digital measurement tools for greater accuracy.

Thickness: Specifying the Asphalt Layer Depth

The Thickness represents the depth of the asphalt layer, typically measured in inches. It’s vital to convert inches to feet before using the formula. To convert inches to feet, divide the thickness in inches by 12.

- Typical Asphalt Thicknesses: Driveways generally require 2-4 inches of asphalt, while roads can range from 4 inches for residential streets to 12+ inches for highways, depending on the anticipated traffic load. Consult local building codes and engineering specifications for the required thickness for your specific project.

- Compaction Considerations: Asphalt compacts during the paving process. This formula doesn’t account for compaction. The density component indirectly addresses compaction.

Density: Factoring in Asphalt Weight

Density refers to the weight of asphalt per cubic foot, typically measured in pounds per cubic foot (lbs/ft³). This value varies based on the asphalt mix design.

- Typical Asphalt Density: Asphalt density typically ranges from 140 to 150 lbs/ft³. A value of 145 lbs/ft³ is often used as a general average. Always verify the density of the specific asphalt mix being used for your project. Request the density information from your asphalt supplier.

- Mix Design Impact: The aggregate type, binder content, and other factors in the asphalt mix design significantly influence its density.

The Constant: Dividing by 2000

The division by 2000 converts the result from pounds to tons. Since a ton equals 2000 pounds, this step is essential for obtaining the final asphalt tonnage estimate.

Applying the Formula: A Step-by-Step Example

Let’s illustrate the asphalt tonnage formula with a practical example:

-

Scenario: Paving a rectangular driveway 50 feet long and 10 feet wide with a 3-inch thick layer of asphalt. The asphalt density is 145 lbs/ft³.

-

Area Calculation: Area = Length x Width = 50 ft x 10 ft = 500 ft²

-

Thickness Conversion: Thickness = 3 inches / 12 inches/foot = 0.25 ft

-

Asphalt Tonnage Calculation:

Asphalt Tonnage = (Area x Thickness x Density) / 2000

Asphalt Tonnage = (500 ft² x 0.25 ft x 145 lbs/ft³) / 2000

Asphalt Tonnage = (18125) / 2000

Asphalt Tonnage = 9.06 tons (approximately)

Therefore, approximately 9.06 tons of asphalt would be required for this driveway.

Factors That Can Affect Asphalt Tonnage Estimates

While the asphalt tonnage formula provides a solid foundation for estimating, several factors can influence the actual tonnage required.

- Waste Factor: Account for material waste due to spillage, uneven surfaces, and compaction variations. A waste factor of 5-10% is generally recommended.

- Calculate waste: Estimated tonnage * waste percentage. Add this value to the estimated tonnage from the main formula.

- Subgrade Condition: An unstable or poorly prepared subgrade can lead to increased asphalt consumption as the asphalt fills voids and compensates for irregularities.

- Compaction Rate: While the density factor partially accounts for compaction, variations in compaction techniques and equipment can impact the final tonnage.

- Asphalt Mix Variations: Subtle differences in asphalt mix designs between batches can influence the density and, consequently, the tonnage required.

- Equipment Calibration: Ensure paving equipment is properly calibrated to deliver the desired asphalt thickness consistently.

Tools and Resources for Tonnage Calculation

Several tools and resources can assist in accurately calculating asphalt tonnage:

- Online Calculators: Numerous websites offer free asphalt tonnage calculators. While convenient, always double-check the input values and the underlying formula.

- Spreadsheet Software: Using spreadsheet software like Microsoft Excel or Google Sheets allows for custom calculations, incorporating waste factors and other variables.

- Construction Estimating Software: Advanced construction estimating software provides comprehensive tools for material estimation, including asphalt tonnage calculations.

By understanding the components of the asphalt tonnage formula and accounting for potential influencing factors, you can significantly improve the accuracy of your project estimates and avoid costly surprises.

Asphalt Tonnage Formula FAQs

Here are some common questions readers have about calculating asphalt tonnage. Hopefully these answers will help you nail your project estimates!

What does the asphalt tonnage formula actually tell me?

The asphalt tonnage formula allows you to estimate the total weight of asphalt you’ll need for a paving project. Knowing this helps you budget accurately and ensure you order the correct amount of material, reducing waste and extra costs. It essentially translates the volume of asphalt needed into a weight.

Why is it important to calculate asphalt tonnage accurately?

Accurate asphalt tonnage calculation prevents over-ordering (wasting money) or under-ordering (causing project delays). It ensures you have enough asphalt to complete the job without unnecessary surplus, optimizing resource use and project efficiency.

What are the key factors that influence the asphalt tonnage formula?

The most important factors are the area you’re paving (length and width), the desired asphalt thickness, and the density of the specific asphalt mix you are using. Density will vary slightly, so confirming this with your supplier is crucial for accurate asphalt tonnage calculation.

Where can I find the asphalt density needed for the formula?

Typically, the density of your specific asphalt mix will be provided by your asphalt supplier. They should be able to give you the weight per cubic foot or cubic yard. Using the correct density is critical for getting an accurate asphalt tonnage estimate.

So, that’s the lowdown on the asphalt tonnage formula! Hopefully, you’ve got a better handle on how to estimate those projects now. Go nail those bids!