Understanding the behavior of materials like the Silver-Copper system is critical for advancements in materials science. The ag-cu phase diagram, a fundamental tool in this field, illustrates the thermodynamic stability of different phases as a function of temperature and composition. The National Institute of Standards and Technology (NIST) provides comprehensive datasets which enable precise construction of these diagrams. Such diagrams aid researchers and engineers in optimizing alloy properties, a key focus for organizations like the ASM International. By utilizing computational tools such as Thermo-Calc, engineers can predict the phase evolution of materials described by the ag-cu phase diagram under diverse processing conditions.

Decoding the Ag-Cu Phase Diagram: A Comprehensive Guide

The "ag-cu phase diagram" (silver-copper phase diagram) is a vital tool for materials scientists, engineers, and anyone working with silver-copper alloys. This guide provides a structured approach to understanding this diagram, enabling you to predict alloy behavior at different temperatures and compositions.

1. Introduction to Phase Diagrams and Their Importance

Phase diagrams are graphical representations that show the equilibrium phases present in a material system as a function of temperature, pressure, and composition. For binary systems like Ag-Cu, we usually focus on temperature and composition.

- What is a Phase? A phase is a physically distinct and chemically homogeneous portion of a system. For example, solid silver, solid copper, and liquid mixture are all different phases.

- Why are Phase Diagrams Important?

- Predicting microstructure of alloys.

- Designing heat treatments for specific properties.

- Understanding melting and solidification behavior.

- Controlling the properties of alloy products.

2. Understanding the Ag-Cu Phase Diagram’s Axes and Key Features

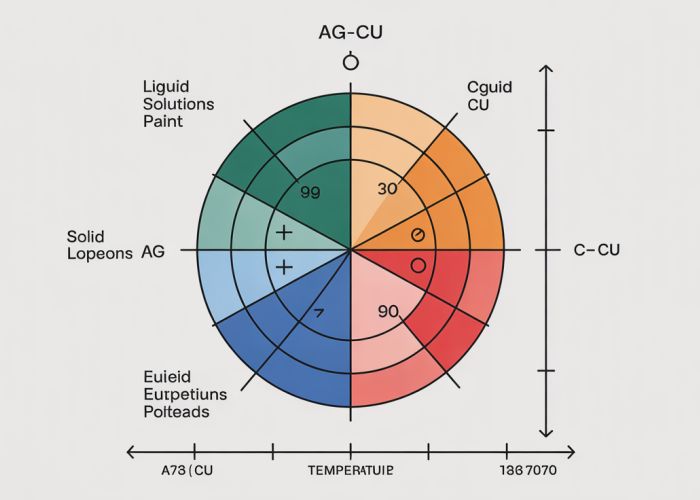

The Ag-Cu phase diagram typically plots temperature (y-axis) against composition (x-axis), where composition represents the weight or atomic percentage of copper in the silver-copper alloy. The diagram is divided into different regions, each representing a stable phase or a mixture of phases.

2.1 Key Features of the Ag-Cu Phase Diagram

- Liquidus Line: The line above which the alloy is entirely liquid.

- Solidus Line: The line below which the alloy is entirely solid.

- Alpha (α) Phase: This is a solid solution of copper in silver. It’s a silver-rich phase.

- Beta (β) Phase: This is a solid solution of silver in copper. It’s a copper-rich phase.

- Eutectic Point: A specific composition and temperature where the liquid phase transforms directly into a mixture of two solid phases (α + β). This is a crucial feature for Ag-Cu alloys.

- Solvus Lines: These lines show the solubility limits of copper in silver (for the α phase) and silver in copper (for the β phase) as a function of temperature.

2.2 Axes Representation

| Axis | Represents | Units |

|---|---|---|

| Y-axis | Temperature | °C or °F |

| X-axis | Composition (Ag or Cu) | wt% or at% |

3. Interpreting the Ag-Cu Phase Diagram: A Step-by-Step Guide

Using the Ag-Cu phase diagram involves understanding the phase(s) present at a given temperature and composition. This can be determined by locating the point corresponding to your alloy’s composition and temperature on the diagram.

3.1 Determining the Phases Present

- Locate the Point: Find the point on the diagram corresponding to your alloy’s composition (e.g., 70 wt% Cu, 30 wt% Ag) and temperature (e.g., 800°C).

- Identify the Region: Determine which region of the phase diagram this point falls into. Each region represents a specific phase or mixture of phases.

- Identify the Phase(s): If the point falls within a single-phase region, that phase is the stable phase. If it falls within a two-phase region, both phases represented in that region are present.

3.2 Calculating Phase Compositions

When a point falls within a two-phase region, you can determine the composition of each phase using the tie line and the lever rule.

- Draw a Tie Line: At the given temperature, draw a horizontal line (the tie line) across the two-phase region, connecting the boundaries of the region.

- Find the Compositions: The composition of each phase is given by the point where the tie line intersects the boundary of that phase’s region.

- Apply the Lever Rule: The lever rule allows you to calculate the relative amounts (fractions) of each phase. The fraction of a phase is proportional to the length of the tie line opposite that phase, divided by the total length of the tie line.

For example, consider an alloy of composition ‘C’ within the α + β region:

Fraction of α phase = (Composition of β – C) / (Composition of β – Composition of α)

Fraction of β phase = (C – Composition of α) / (Composition of β – Composition of α)

3.3 Example Scenario

Consider an Ag-Cu alloy with 40 wt% copper at 800°C.

- Locate the point (40 wt% Cu, 800°C) on the phase diagram. This point falls within the α + Liquid region.

- Draw a tie line across the α + Liquid region at 800°C.

- The tie line intersects the α phase boundary at approximately 8 wt% Cu. This is the composition of the α phase.

- The tie line intersects the Liquid phase boundary at approximately 62 wt% Cu. This is the composition of the Liquid phase.

- Apply the lever rule to calculate the fractions of α and Liquid.

4. The Eutectic Transformation in Ag-Cu Alloys

The eutectic point is a special feature in the Ag-Cu phase diagram, typically around 71.9 wt% Ag (28.1 wt% Cu) and 779°C.

- Eutectic Reaction: Liquid (71.9 wt% Ag) → α (8.0 wt% Cu) + β (92.0 wt% Cu) upon cooling below 779°C.

- Eutectic Microstructure: Alloys with eutectic composition solidify into a characteristic fine-grained microstructure consisting of alternating layers (lamellae) of α and β phases. This microstructure often exhibits superior mechanical properties compared to other compositions.

- Hypoeutectic and Hypereutectic Alloys: Alloys with compositions to the left of the eutectic point are hypoeutectic, while those to the right are hypereutectic. These alloys solidify in a different manner, involving the formation of a primary α or β phase before the eutectic reaction occurs.

5. Practical Applications of the Ag-Cu Phase Diagram

The Ag-Cu phase diagram has wide-ranging applications in various fields:

- Soldering: Ag-Cu alloys near the eutectic composition are excellent soldering materials due to their low melting point and good wetting properties.

- Jewelry: Silver-copper alloys are used in jewelry making, with different compositions tailored for specific properties like hardness and tarnish resistance.

- Electrical Contacts: These alloys offer a good balance of conductivity and mechanical strength for electrical contacts.

- Dental Amalgams: Certain Ag-Cu alloys are used in dental fillings.

6. Factors Affecting Phase Diagrams

While the Ag-Cu phase diagram is a useful tool, it is important to remember that it represents equilibrium conditions. Deviations from equilibrium can occur due to factors such as:

- Cooling Rate: Rapid cooling can suppress the formation of equilibrium phases and lead to non-equilibrium microstructures.

- Pressure: While typically not considered for Ag-Cu alloys, pressure can affect phase stability.

- Impurities: The presence of impurities can alter the phase diagram.

It is important to consider these factors when applying the phase diagram to real-world scenarios.

Understanding the Ag-Cu Phase Diagram: Your Questions Answered

Here are some frequently asked questions to further clarify the Ag-Cu phase diagram and its applications.

What exactly does the Ag-Cu phase diagram tell us?

The Ag-Cu phase diagram shows the phases that are stable at different temperatures and compositions of silver (Ag) and copper (Cu) alloys. It allows you to predict the microstructure and properties of an Ag-Cu alloy at a given temperature and composition, crucial for material selection and processing.

What are the key features to look for in the Ag-Cu phase diagram?

Pay attention to the liquidus and solidus lines, which define the melting range. Note the eutectic point (at around 72% Ag and 780°C), where the liquid solidifies directly into two solid phases simultaneously. The Ag-Cu phase diagram also shows regions of solid solutions (alpha and beta).

How can the Ag-Cu phase diagram help in selecting alloys for specific applications?

By using the Ag-Cu phase diagram, you can choose an alloy composition that will provide the desired properties at the operating temperature. For example, if you need a low melting point alloy, you might select a composition close to the eutectic point on the Ag-Cu phase diagram.

Why is understanding the eutectic point so important for Ag-Cu alloys?

The eutectic point on the Ag-Cu phase diagram is significant because alloys with this specific composition have the lowest melting point. These alloys are commonly used in solders because of their ability to form strong bonds at relatively low temperatures.

So, that’s a wrap on diving into the ag-cu phase diagram! Hopefully, you found some nuggets of wisdom in there. Now, go forth and conquer those material challenges!